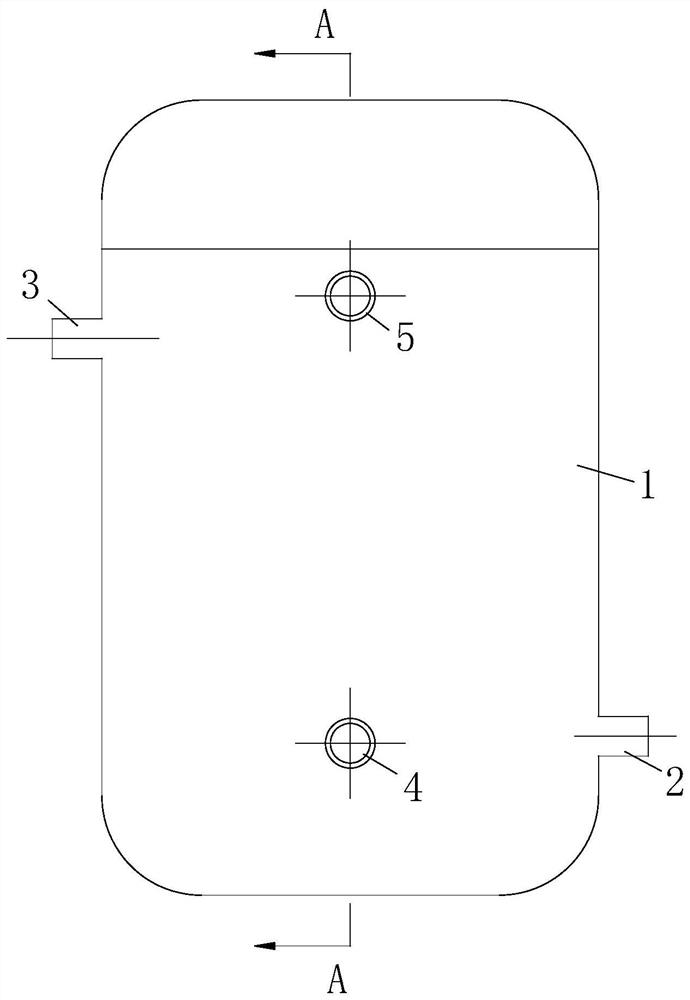

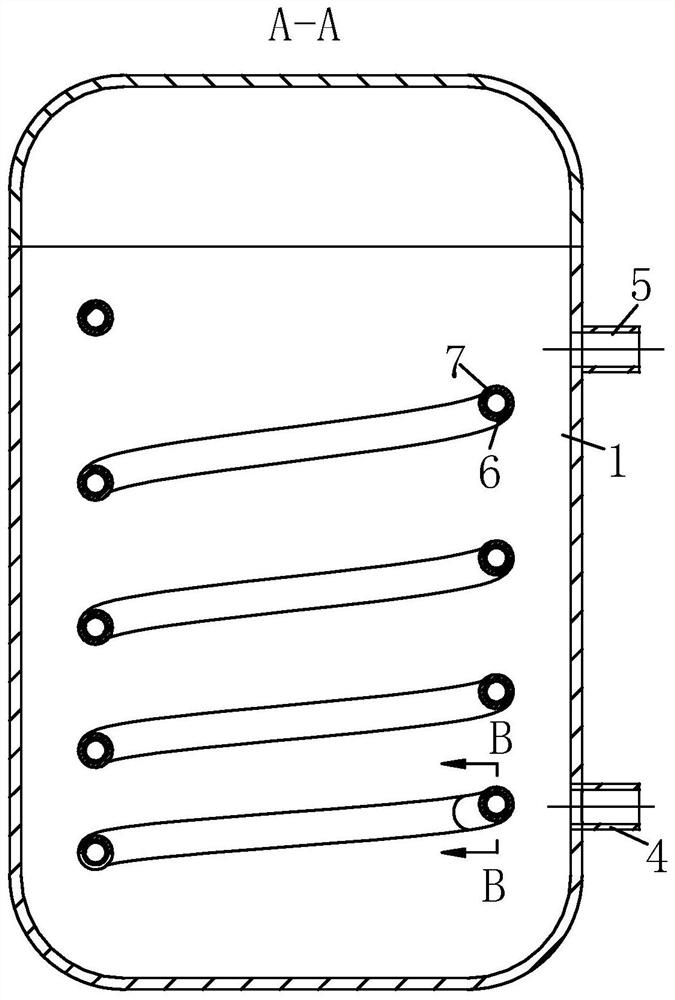

A liquid chlorine vaporizer

A vaporizer and liquid chlorine technology, applied in the direction of indirect heat exchangers, heat exchanger sealing devices, lighting and heating equipment, etc., can solve the problems of corrosion perforation, box corrosion, leakage, etc., and achieve enhanced strength and less crack leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

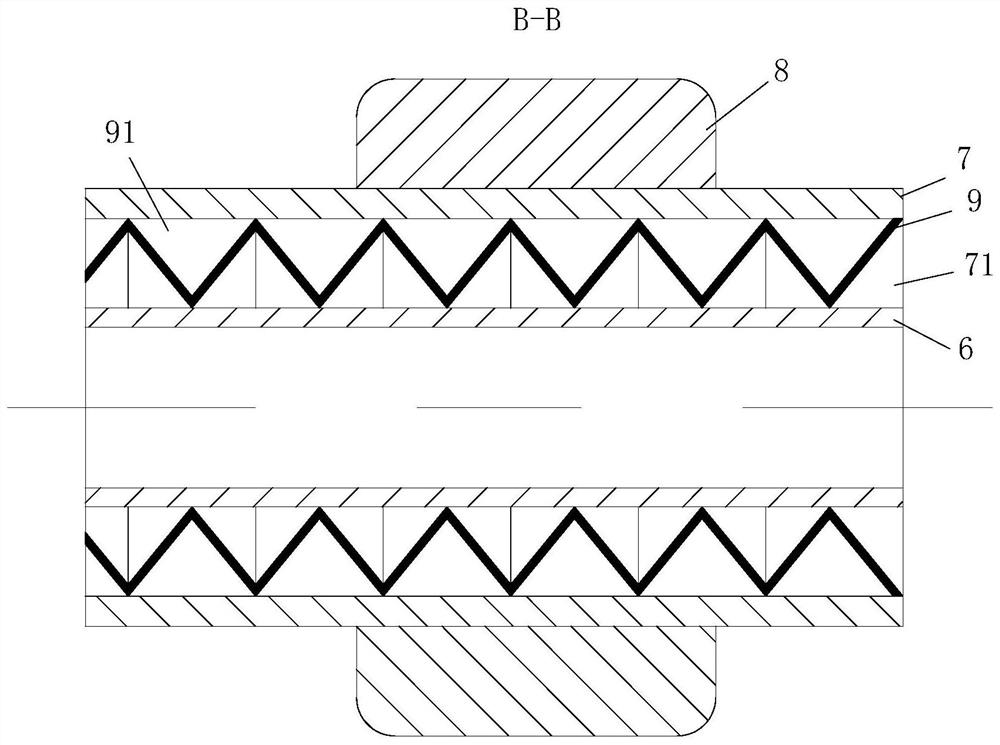

[0033] As an embodiment of the present invention, the V-shaped flap 91 is provided with a spring assembly 911, the spring assembly 911 is composed of two small springs, the small springs are connected by a connecting plate, and the spring assembly 911 is composed of It is made of porous water-absorbing anti-corrosion material, and the two ends of the spring assembly 911 are installed at the end of each V-shaped flap 91; when working, chlorine gas flows into the V-shaped flap 91 in the isolation layer 9 from the leak point of the vaporization pipeline 6, The spring assembly 911 can absorb the moisture in the chlorine gas, and at the same time, the air pressure pushes the inclined plate of the V-shaped folding plate 91 to squeeze to both ends, and the spring assembly 911 at the end of the V-shaped folding plate 91 at the leakage point gives a certain force to the inclined plates at both ends. Tensile force, the spring assembly 911 on the V-shaped folded plate 91 on both sides adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com