Sustainable determination system for remanufacturing system based on energy, environment and economy

A remanufacturing and sustainable technology, applied in the field of remanufacturing system sustainability measurement system, can solve the problems of no extension of remanufacturing process, excessive energy consumption, subjectivity and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

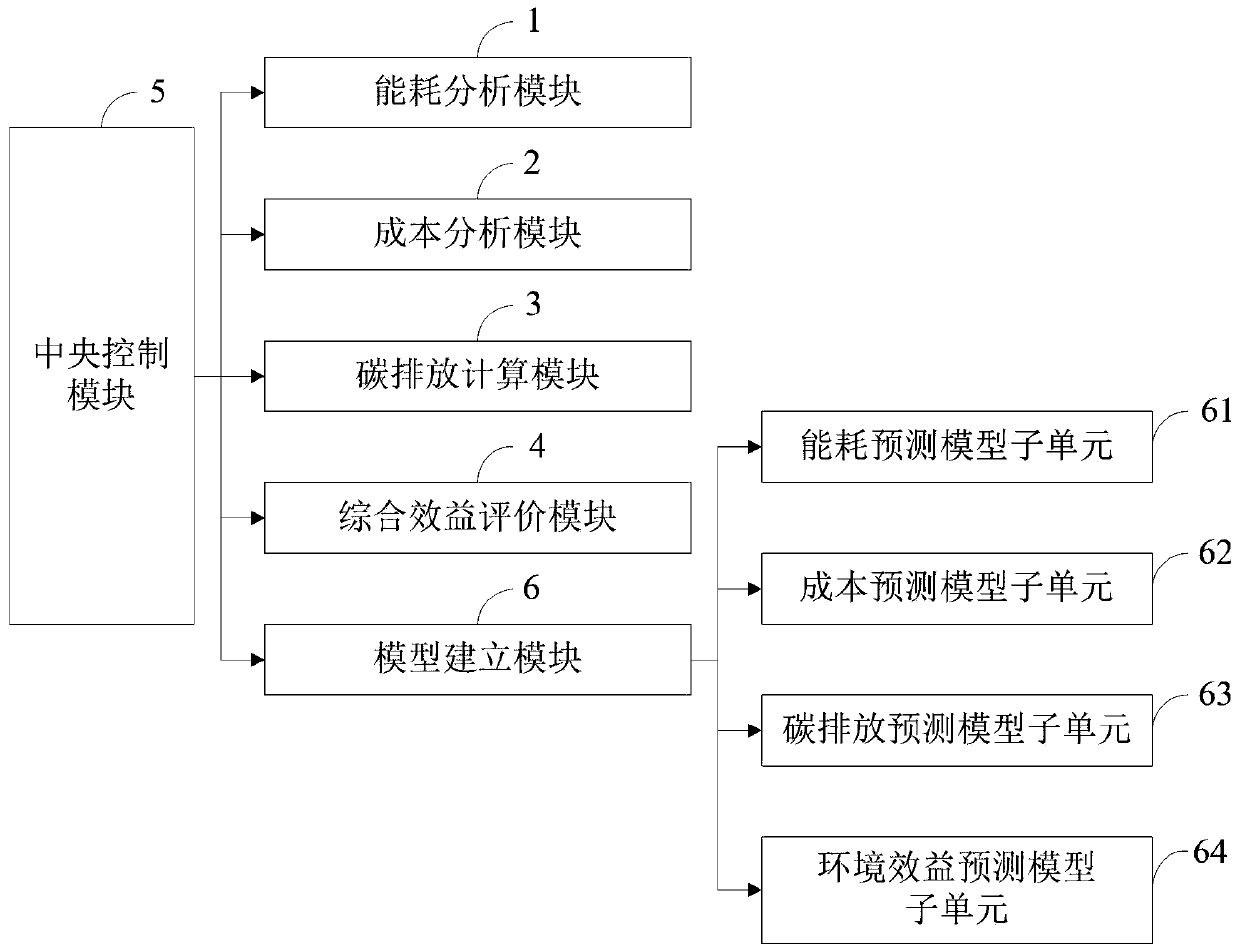

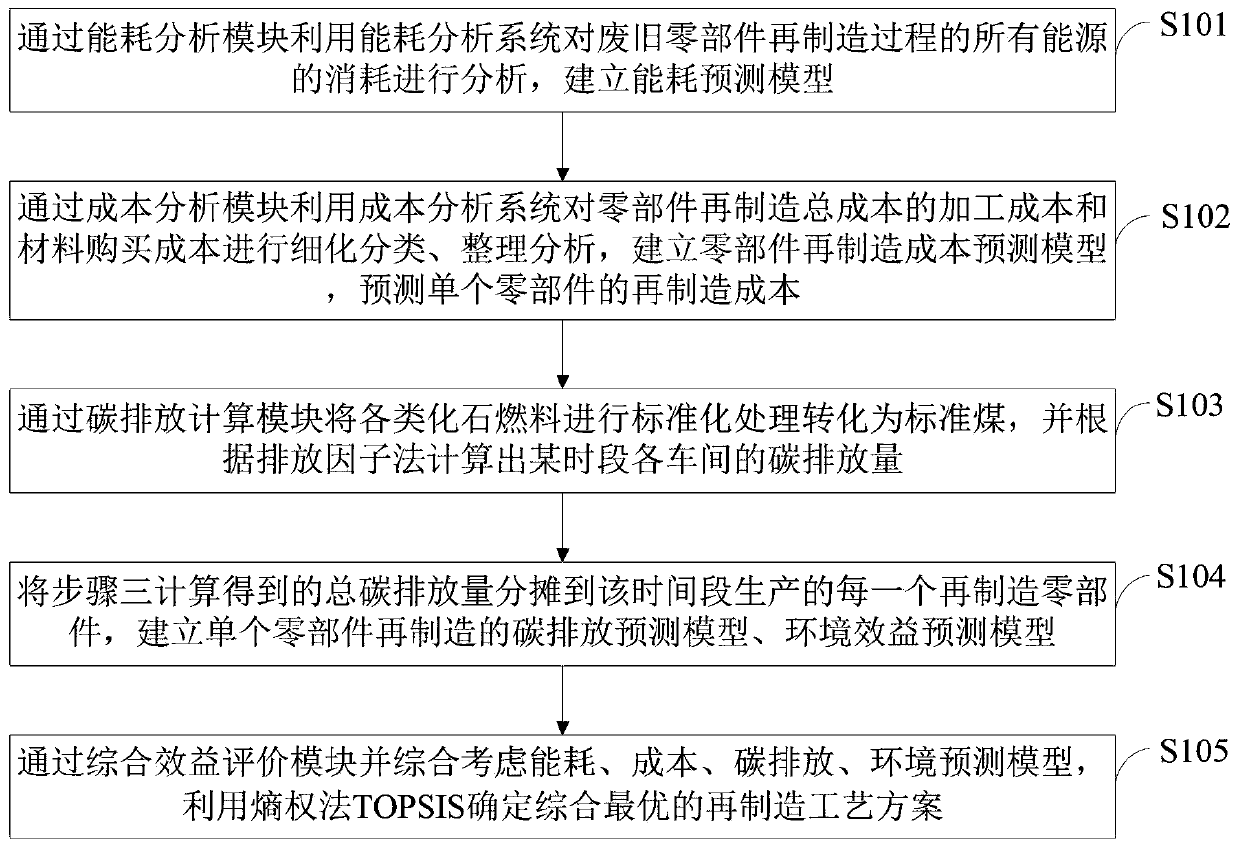

Method used

Image

Examples

Embodiment 1

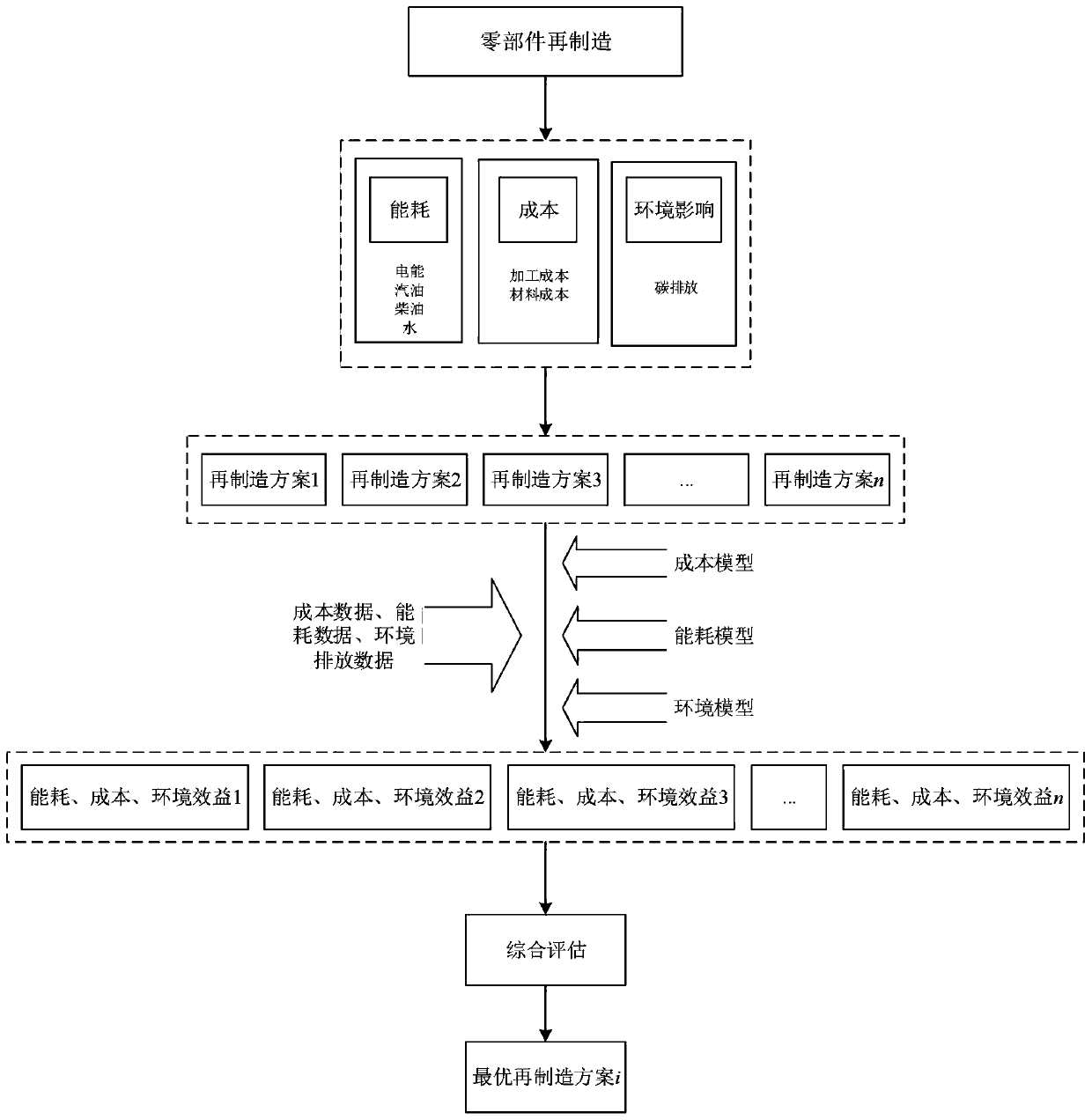

[0243] 1. Goal

[0244] The object of the present invention is to evaluate the sustainability of the remanufacturing system and find a comprehensive and optimal remanufacturing scheme by comprehensively considering the indicators such as environment, cost, and energy consumption. Taking the waste parts that can be remanufactured and repaired as the research object, the waste parts can be repaired through remanufacturing so that they can meet or even exceed the quality and performance of new parts. Each stage of remanufacturing includes cleaning, testing, repairing, retesting, packaging, transportation, etc. The boundary of the waste parts remanufacturing system is as follows: Figure 4 shown.

[0245] (1) method

[0246] The quality of parts remanufacturing scheme directly affects the cost of remanufacturing, the quality of parts and the time of remanufacturing. The optimization of remanufacturing scheme can effectively improve the quality of remanufactured parts, reduce the...

Embodiment 2

[0340] The invention establishes a comprehensive optimal remanufacturing sustainability evaluation model based on economy, energy and environment, and verifies the practicability of the method in actual production. Case analysis includes the following points: research object, result, discussion.

[0341] (1) Research object

[0342] The embodiment of the present invention aims to establish a remanufacturing sustainability evaluation model of the C6132A1 machine tool spindle of Guangzhou Machine Tool Works. The main shaft is a rotating shaft, and it is easy to cause torsional fatigue and bending fatigue fracture under the alternating load of bending and torsion. During high-speed operation, severe vibration will cause excessive deformation, cracks, and even fatigue fracture of the spindle. Spindle remanufacturing includes three main stages: cleaning inspection, surface repair and machining. Each process will generate certain costs, energy consumption and carbon dioxide emissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com