Method for preparing environment-friendly waterproof plant asphalt by using plant raw materials

A technology of plant asphalt and plant raw materials, which is applied in the direction of processing tar asphalt/petroleum asphalt/natural asphalt by chemical methods, which can solve the problems of environmental pollution, high cost, and low utilization rate of waste asphalt, and achieve broad application prospects and high equipment efficiency. The effect of low requirements and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

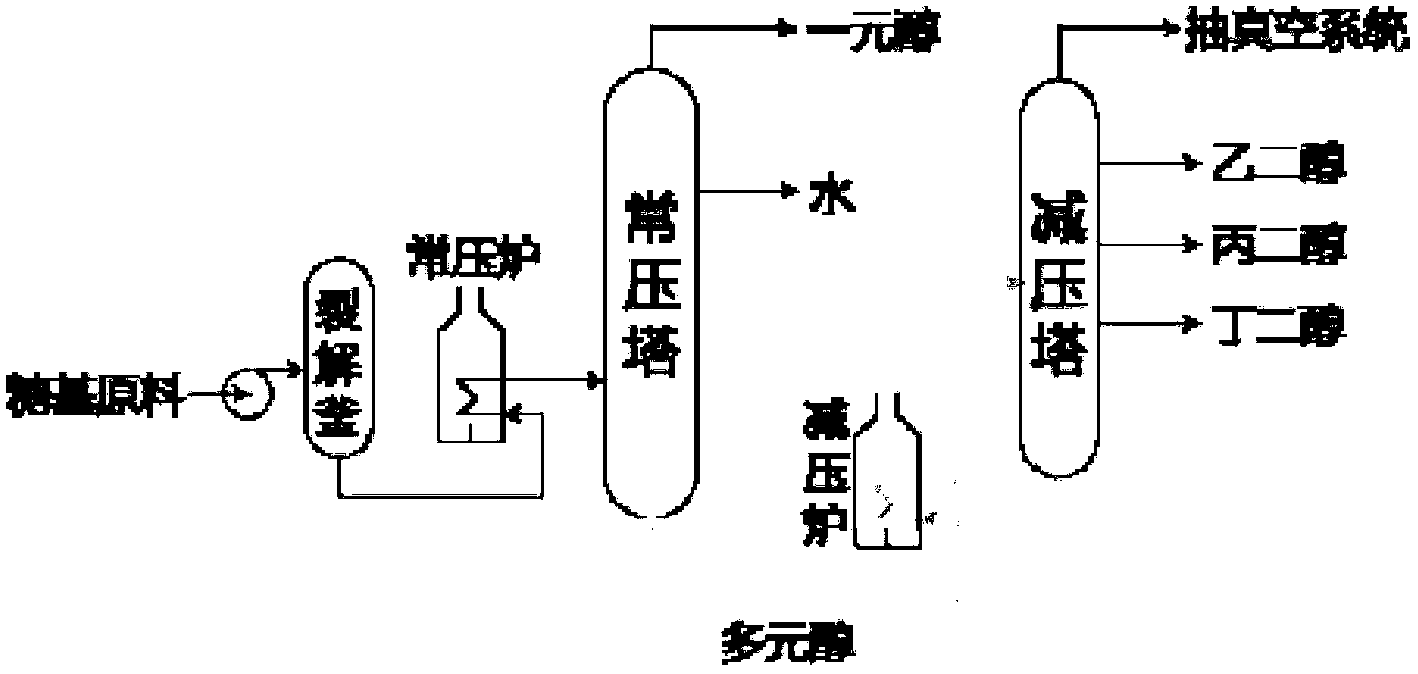

Method used

Image

Examples

Embodiment 1

[0037] Import 300 kilograms of 808 plant asphalt at 230-240 degrees from the separation tower into a 1 cubic esterification kettle commonly used in the polyester industry, add 30 kilograms of phthalic anhydride, stir in the temperature range of 190-210 degrees, and carry out esterification Cyclization reaction; the initial pressure of the reaction is zero. After 34 minutes, the pressure gauge began to display the pressure; at about 90 minutes, on the recorded pressure-time curve chart, the maximum pressure change rate was displayed, and the pressure was 0.28MPa (2.8 kg); at 200 minutes, the pressure was stable at 0.35MPa; After 220 minutes, slowly open the valve of the esterification outlet pipe of the esterification kettle, put the outlet pipe into the condensate pool, and release the water to relieve the pressure. After the pressure is relieved, the brown-black 828-1 vegetable asphalt with a temperature of 215 degrees is obtained in the kettle.

[0038] Sampling measurement...

Embodiment 2

[0041] Import 300 kg of 808 vegetable asphalt at 230-240 ° C from the fractionating tower into a 1 cubic esterification kettle commonly used in the polyester industry, add 45 kg of phthalic anhydride, stir in the temperature range of 190-210 ° C, and carry out esterification Cyclization reaction; the initial pressure of the reaction is zero. After 30 minutes, the pressure gauge began to display the pressure; at about 100 minutes, it showed the maximum pressure change rate, and the pressure at this time was 0.29MPa (2.9 kg); at 210 minutes, the pressure was stable at 0.37MPa; after 240 minutes, release the water to relieve the pressure . After the pressure is released, a 217°C, dark brown-black 828-2 plant pitch is obtained in the kettle.

[0042] Sampling measurement shows that 828-2 plant asphalt is also insoluble in water; compare the 828-2 plant asphalt sample at 200 degrees with the 90# petroleum asphalt at 200 degrees, the former has no obvious smoke and no serious odor ...

Embodiment 3

[0045] With 300 kilograms of plant asphalt obtained in Example 1 828-1 at 213 ° C, import in a 10-liter stirring tank, add 1350 kilograms of 90# petroleum asphalt, and 750 kilograms of 10# petroleum asphalt, 200 kilograms of machine oil, poly 100 kg of propylene, 200 kg of SBS, 300 kg of waste rubber powder, and 2,000 kg of calcium carbonate; stir for 24 hours in the temperature range of 200-220°C, and discharge. The above-mentioned about 5 tons of materials are used to prepare waterproof asphalt coils on the production line, and the same process is used to prepare waterproof asphalt coils. The low temperature resistance of the finished product was tested, compared with the original process without 828-1 plant asphalt, the low temperature resistance changed from -15°C of the original control sample to -20°C, which indicated that the plant pitch of 828-1 In addition to being used as a substitute for petroleum asphalt, asphalt can also improve the low temperature resistance of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com