Preparation method for casing tofu

A technology of sausage casing and tofu, which is applied in the field of casing tofu preparation, can solve the problems of inability to effectively absorb nutrients, harm human health, and cause life, and achieve the effects of eliminating the need to peel off packaging, convenient cooking, and good eating taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

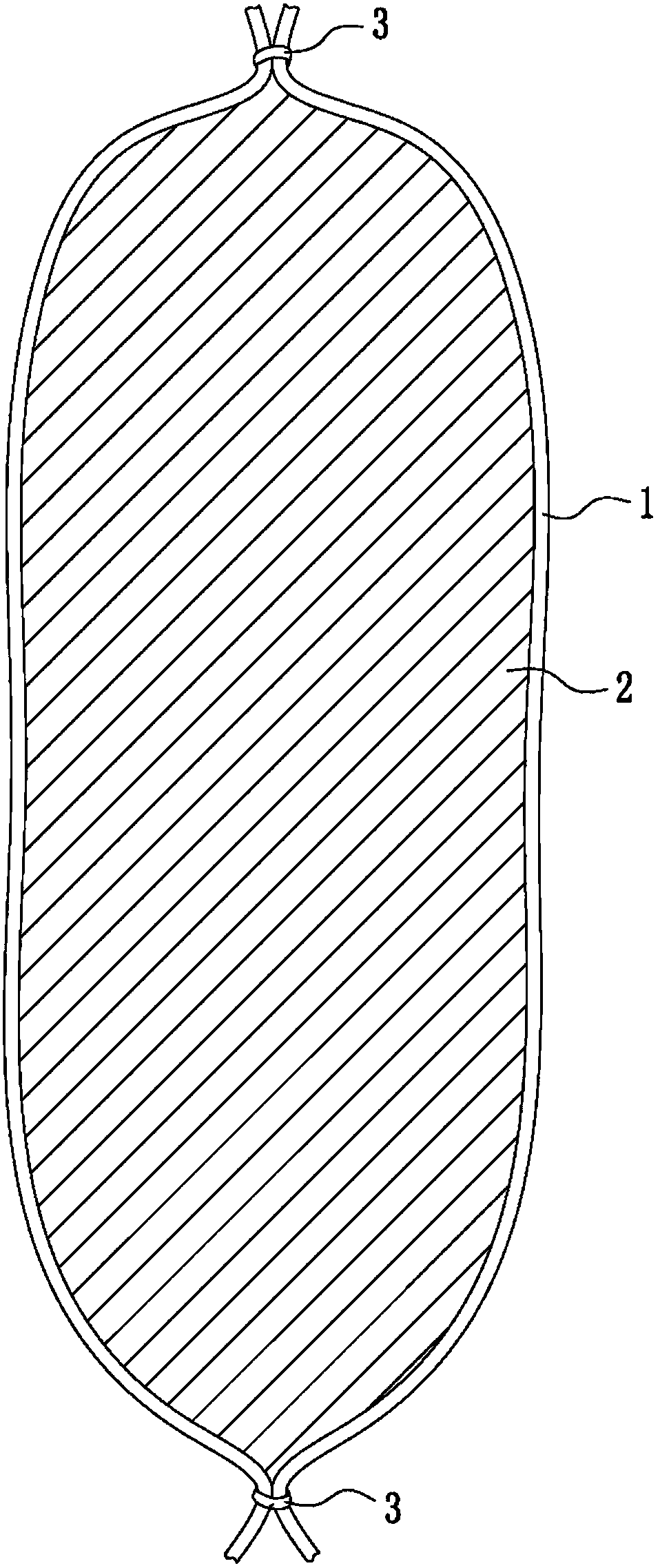

Image

Examples

Embodiment 1

[0020] The invention provides a kind of preparation method of casing bean curd, it comprises the steps:

[0021] The first step is to cook the soymilk: boil the soymilk and keep it at 100°C for 10 to 15 minutes; the steps of the soymilk preparation method are as follows:

[0022] (1), select high-quality non-transgenic soybeans, soak them in drinking water at 9-11°C (the water temperature is preferably 10°C) until the soybeans absorb water and reach saturation, and soak the soybeans until they are saturated for 2 hours, then wash the soybeans; 1 hour is a repeated unit of soaking and washing, repeating 3 times, to remove miasma, plant acid and harmful substances in soybeans;

[0023] (2) Use drinking water at 9-11°C (the water temperature is preferably 10°C), soak and wash the soybeans with a repeat unit of 3 hours, repeat 14 times, further remove phytic acid, and further expand the protein particles in the soybeans ;

[0024] (3) Use drinking water at 9-11°C (the water temp...

Embodiment 2

[0030] A preparation method of casing bean curd, it comprises the steps:

[0031] The first step is to cook the soy milk: boil the soy milk and keep it at 100°C for 10 to 15 minutes, then cool the soy milk and keep the temperature of the soy milk below 40°C, then add food-grade vegetable protein coagulant or glucose Sodium fat and stir well;

[0032] Wherein the preparation method step of this soybean milk is as follows:

[0033] (1), select high-quality non-transgenic soybeans, soak them in drinking water at 9-11°C (the water temperature is preferably 10°C) until the soybeans absorb water and reach saturation, and soak the soybeans until they are saturated for 2 hours, then wash the soybeans; 1 hour is a repeated unit of soaking and washing, repeating 3 times, to remove miasma, plant acid and harmful substances in soybeans;

[0034] (2) Use drinking water at 9-11°C (the water temperature is preferably 10°C), soak and wash the soybeans with a repeat unit of 3 hours, repeat 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com