Multi-purpose rice noodle roll machine

The technology of a rice roll machine and a rack is applied in the field of multi-purpose rice roll machine, which can solve the problems of low utilization rate of thermal energy, slow food production, and increase in use cost, so as to improve the production speed and heat energy utilization rate, and reduce kitchen utensils. The effect of reducing equipment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

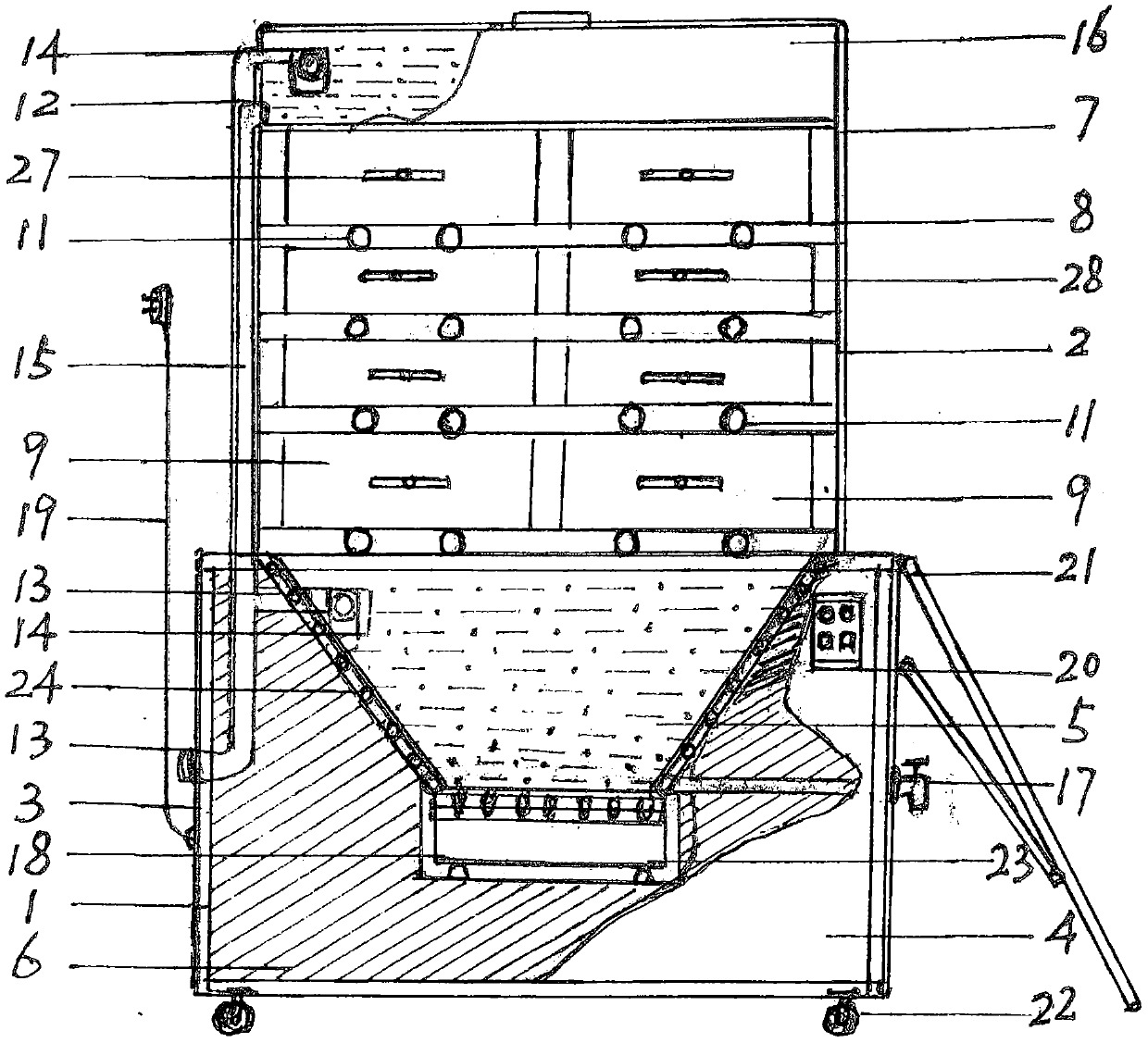

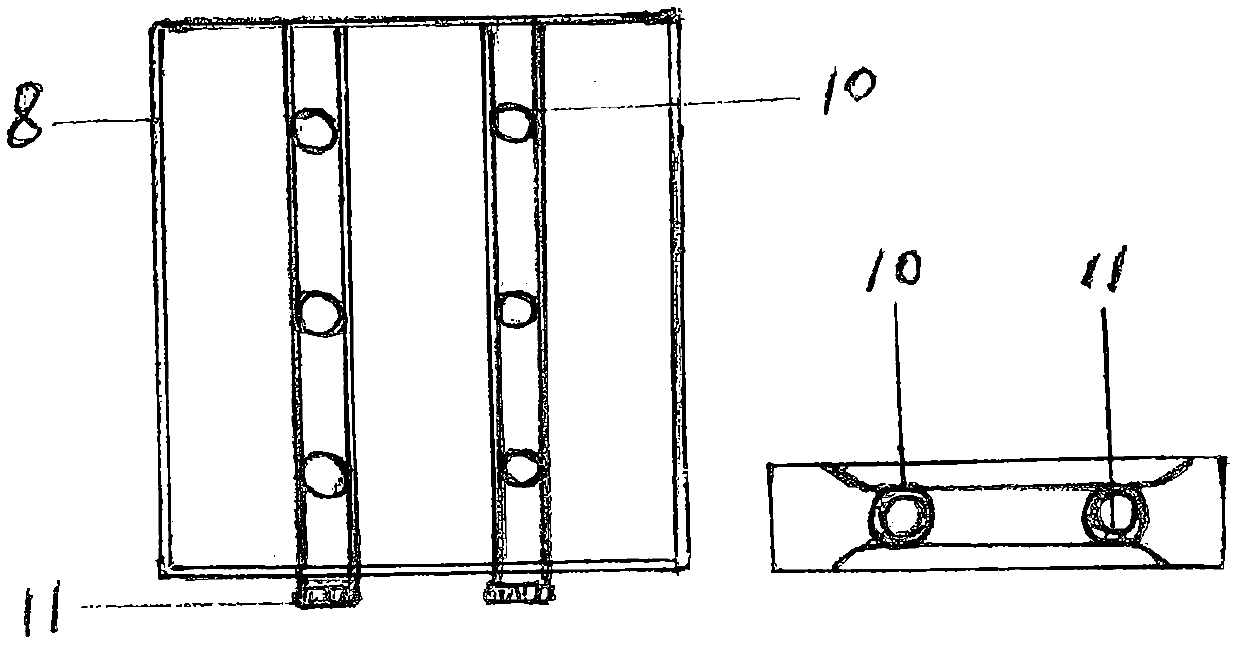

[0017] Embodiment 1: refer to figure 1 , figure 2 The shown multi-purpose intestine powder machine comprises a heating device 1 and a steamer device 2, and the heating device 1 is a vertical furnace composed of a frame 3, a shroud 4, a thermal insulation layer 6, a cooking pot 5 and a heating appliance 18, The steamer device 2 located on the frame 3 and the cooking pot 5 is a drawer-type metal steamer composed of a frame 7, a thermal insulation layer 6, a coaming plate 4, a drawer layer 8, and a steamer 9. The drawer layer 8 A pair of perforated sleeves 10 and a pair of perforated steam regulating drums 11 are arranged in the middle of the eight inner side panels 4 of the frame 7. The special-shaped metal shells, the steaming drawers 9 are arranged on the drawer compartment 8 There are eight metal drawers with the same length and width and different depths, and a set of heat insulation layer 6, water inlet pipe 12, water inlet 13, buoyancy valve 14, water outlet, and water o...

Embodiment 2

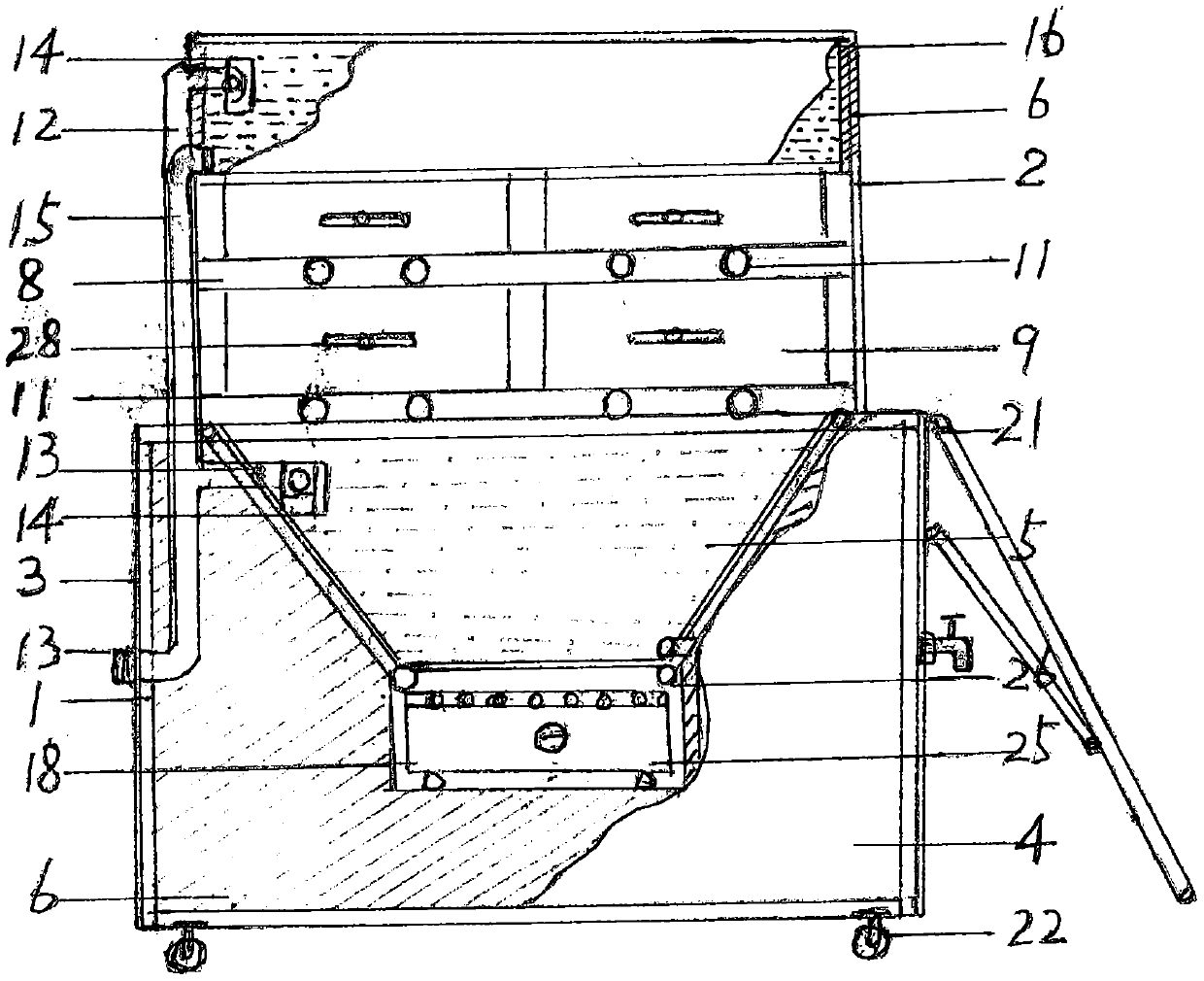

[0024] Embodiment 2: refer to figure 2 , image 3 The shown multi-purpose rice roll machine has roughly the same structure as the multi-purpose rice roll machine in Example 1, except that there are four drawer compartments 8, four steaming drawers 9, and 9 steaming drawers. It includes two large deep-bottomed steel drawers on the lower two drawer compartments 8 and two small shallow-bottomed steel drawers on the upper two drawer compartments 8, which are located on the heating appliance 18 outside the cooking pot 5 It is a set of square fire exhaust gas stove 25 with smoke exhaust duct 26. Compared with Embodiment 1, the design of this intestine powder machine is suitable for the use of catering stores or takeaway stalls with few processing quantities and varieties, and shortage of electric heating energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com