A superhydrophilic/underwater superoleophobic co-deposition coating and preparation method thereof

An underwater superoleophobic and co-deposition technology, applied in antifouling/underwater coatings, water/sewage treatment, adsorbed water/sewage treatment, etc. The effect of mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention has a preparation method of superpocade coating, including the following steps, including the following steps.

[0041] Step 1, the cleaning of the substrate surface,

[0042] Take a 20 × 20mm 2 The base sheet is soaked for 8 to 24 h with anhydrous acetone, and then the ultrasonic ethanol, anhydrous acetone and distilled water are performed, respectively, and finally dry;

[0043] The substrate can be a polymer sheet, a glass sheet, a metal sheet, a screen, a silicon wafer and a fiber cloth;

[0044] Step 2, refer to the existing method, formulate Tris buffer solution or PBS buffer solution,

[0045]The formulation of the TRIS buffer solution is specifically: Tris hydroxymethylmethhane (i.e., Tris), adding distilled water to be dissolved to completely, using acid substances to adjust the pH to 7 to 10, i.e., Tris buffer solution, Tris buffer solution The concentration of 10 to 100 mmol / L; acid substances are one or more of inorganic acid and organic ...

Embodiment 1

[0056] The present invention has a method of preparing a coating coating of super hydrate / underwater superovight, and specifically includes the following steps.

[0057] Step 1, the cleaning of the PE sheet surface,

[0058] Take a 20 × 20mm 2 The PE tablets were soaked for 12h with anhydrous acetone, and anhydrous ethanol, anhydrous acetone and distilled water were used for 10 min, and naturally dried;

[0059] Step 2, the formulation of the Tris buffer solution,

[0060] 0.97 g of trihydroxymethylmethhane (TRI) was accurately weighed, and the mixture was stirred with distilled water to completely, and the pH = 8 of hydrochloric acid was used, and the solution concentration was 80 mmol / L.

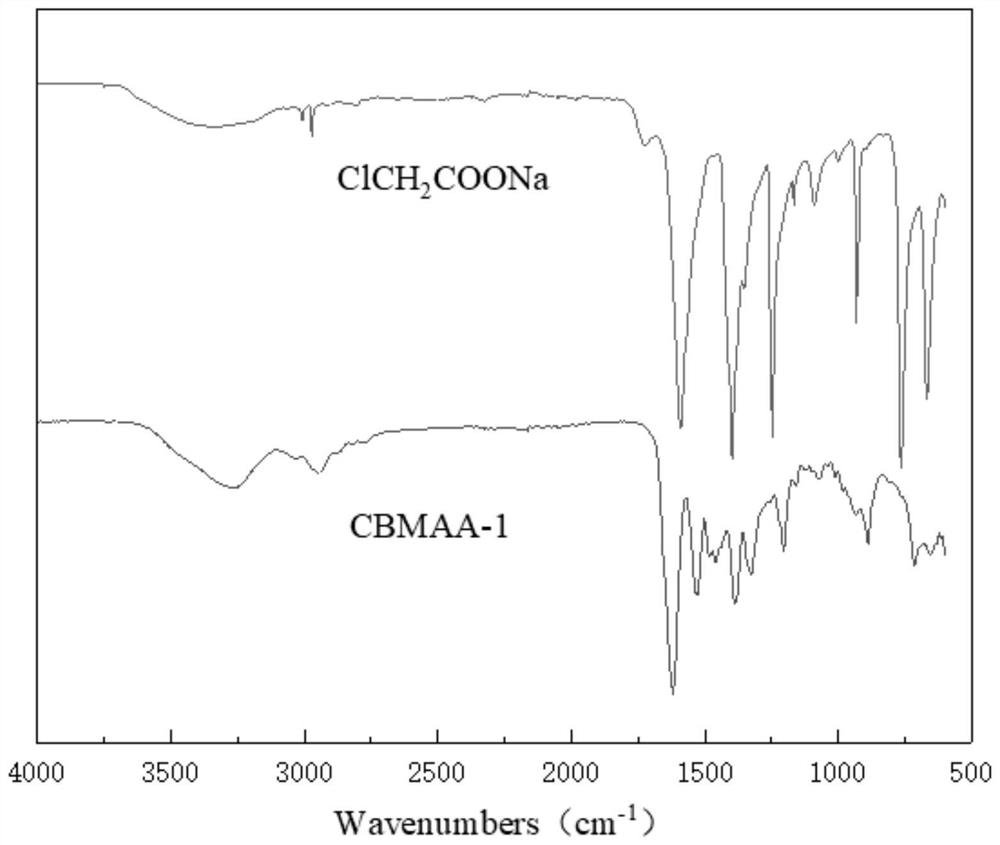

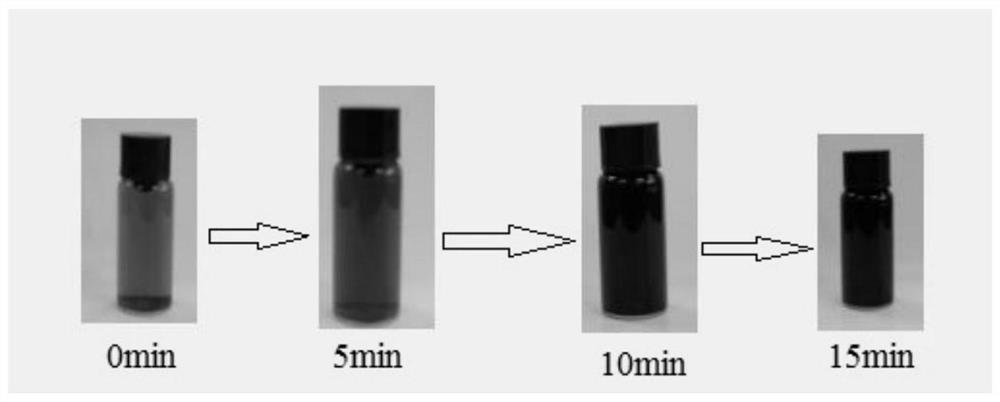

[0061] Step 3, the preparation of the amphoteric ion monomer 1-carboxy-N, N-dimethyl-N-methacrylamide propyl salt (CBMAA-1),

[0062] 2.5 g of N- (3-dimethylamine) methacrylamide (DMAPMA) was sufficiently dissolved with 2 mL of distilled water, and condensate was installed in 100 mL of fou...

Embodiment 2

[0073] The present invention has a method of preparing a coating coating of super hydrate / underwater superovight, and specifically includes the following steps.

[0074] Step 1, the surface of the glass sheet is cleaned,

[0075] Take a 20 × 20mm 2 The glass sheet is soaked for 18 h with anhydrous acetone, and anhydrous ethanol, anhydrous acetone and distilled water are used in sequentially, and naturally dry;

[0076] Step 2, the formulation of the Tris buffer solution,

[0077]0.48 g of trimethylmethylmethhane (TRI) was accurately weighed, and the mixture was stirred with distilled water to completely, and the solution was adjusted to be adjusted to pH = 8.5, and the solution concentration was 40 mmol / L;

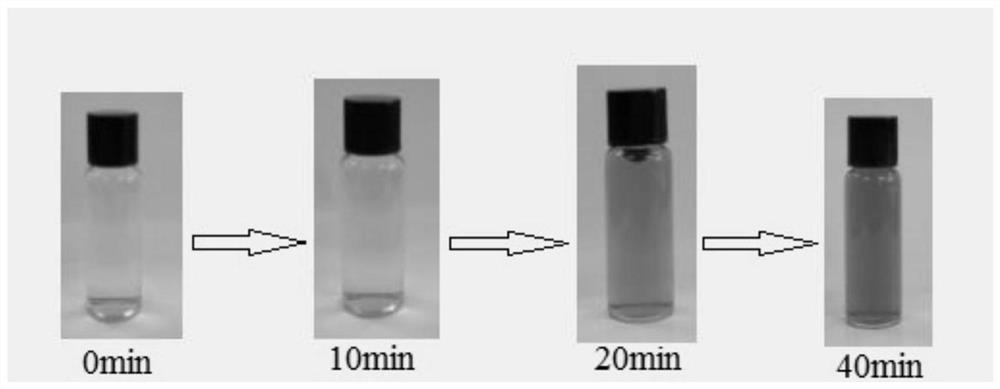

[0078] Step 3, the preparation of dimethylbarboxylatyl methacrylate (CBMA) of gender ion monomeric methacrylate,

[0079] 3.5 g of dimethyl methacrylate (DMAEMA) was sufficiently dissolved with 5 ml of distilled water, and the condensed tube and thermometer were filled wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com