Adjustable feeding mechanism of numerical control machine tool

A CNC machine tool, adjustable technology, applied in metal processing and other directions, can solve the problems of material blockage, jamming, lack of guide parts in the feeding pipe, etc., and achieve the effect of accelerating the discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

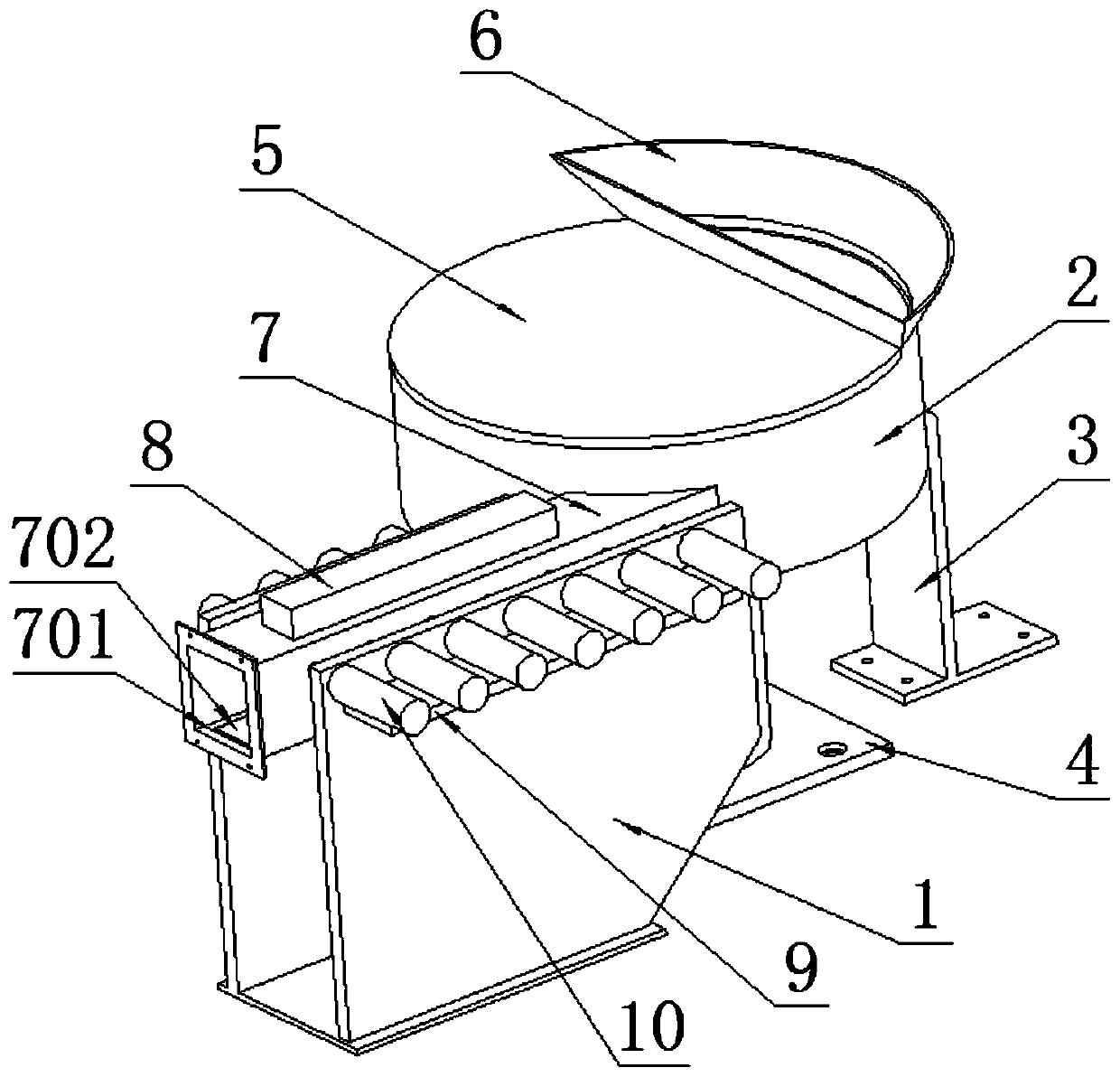

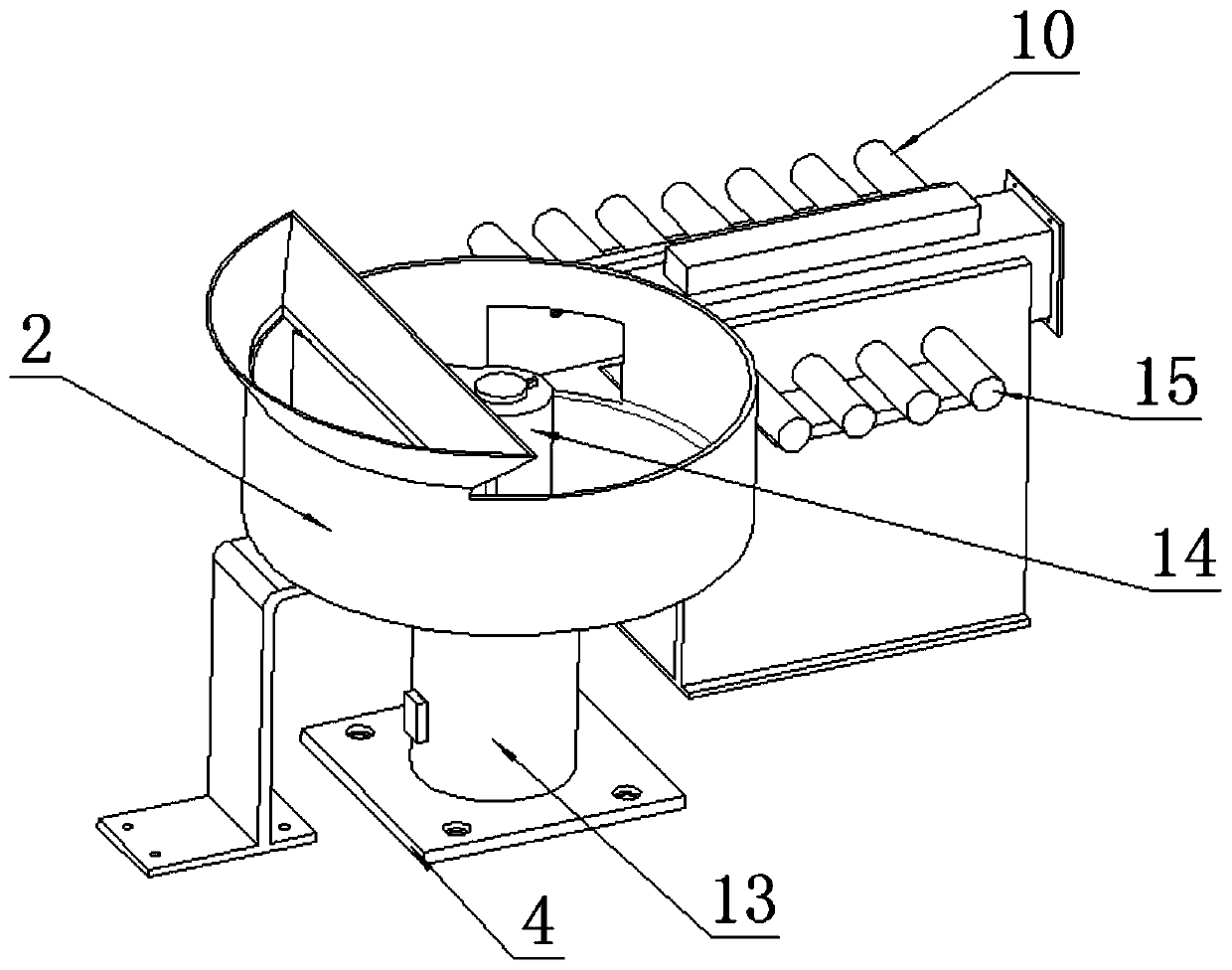

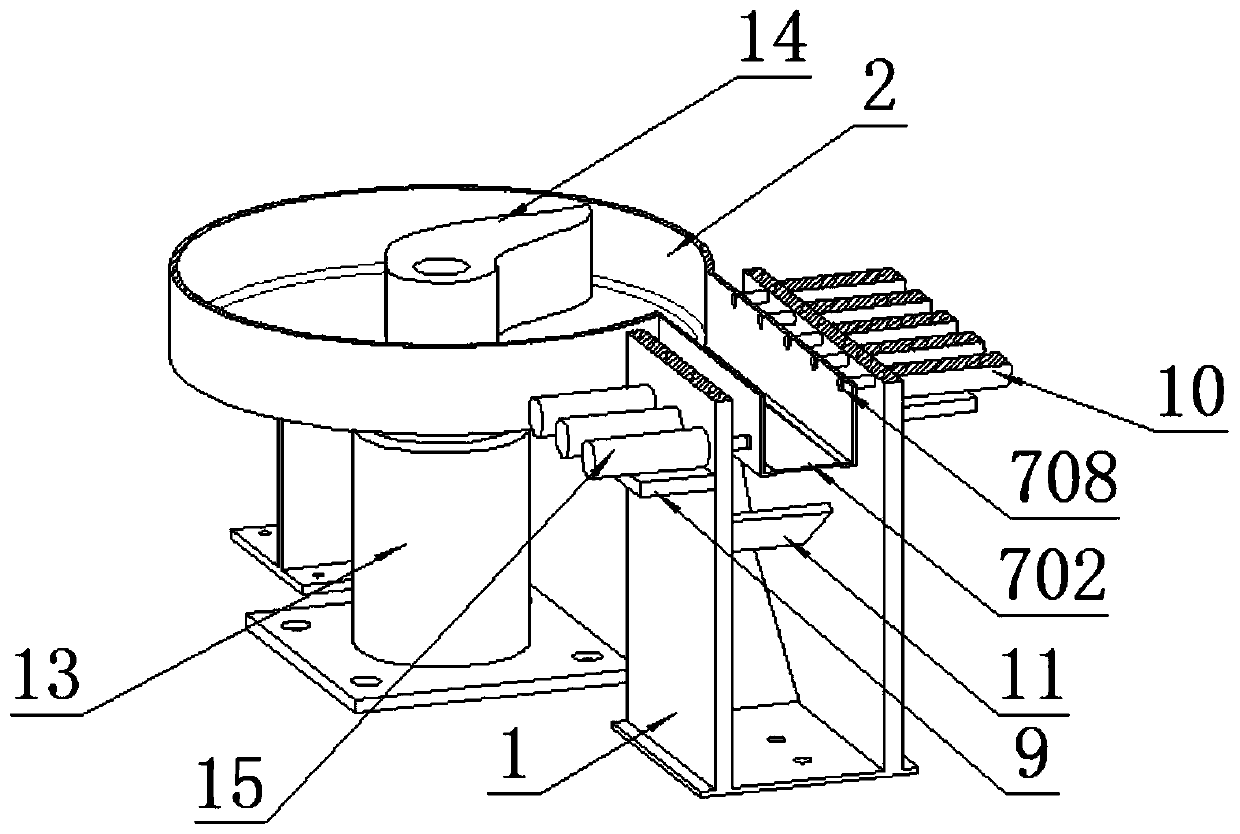

[0032] as attached figure 1 to the attached Figure 10 shown:

[0033] The present invention provides an adjustable feeding mechanism of a numerically controlled machine tool, including a vertical plate 1, a disc-shaped cabin 2, a vertical frame 3, a mounting plate 4, a cabin plate 5, a feeding port 6, a discharging pipe 7, a reserved groove 701, The first accessory plate 702, the second accessory plate 703, the shading 704, the top seat 706, the U-shaped clamp seat 707, the perforation 708, the power seat 8, the fixing plate 9, the right electric cylinder 10, the welding plate 11, the middle electric cylinder 12. The rotary motor 13, the material stopper 14 and the left electric cylinder 15; the vertical plate 1 is left and right, and their inner regions are jointly welded with a rectangular plate structure welding plate 11 in a backward inclined manner. A middle electric cylinder 12 is installed in the middle of the welding plate 11; the rotary motor 13 is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com