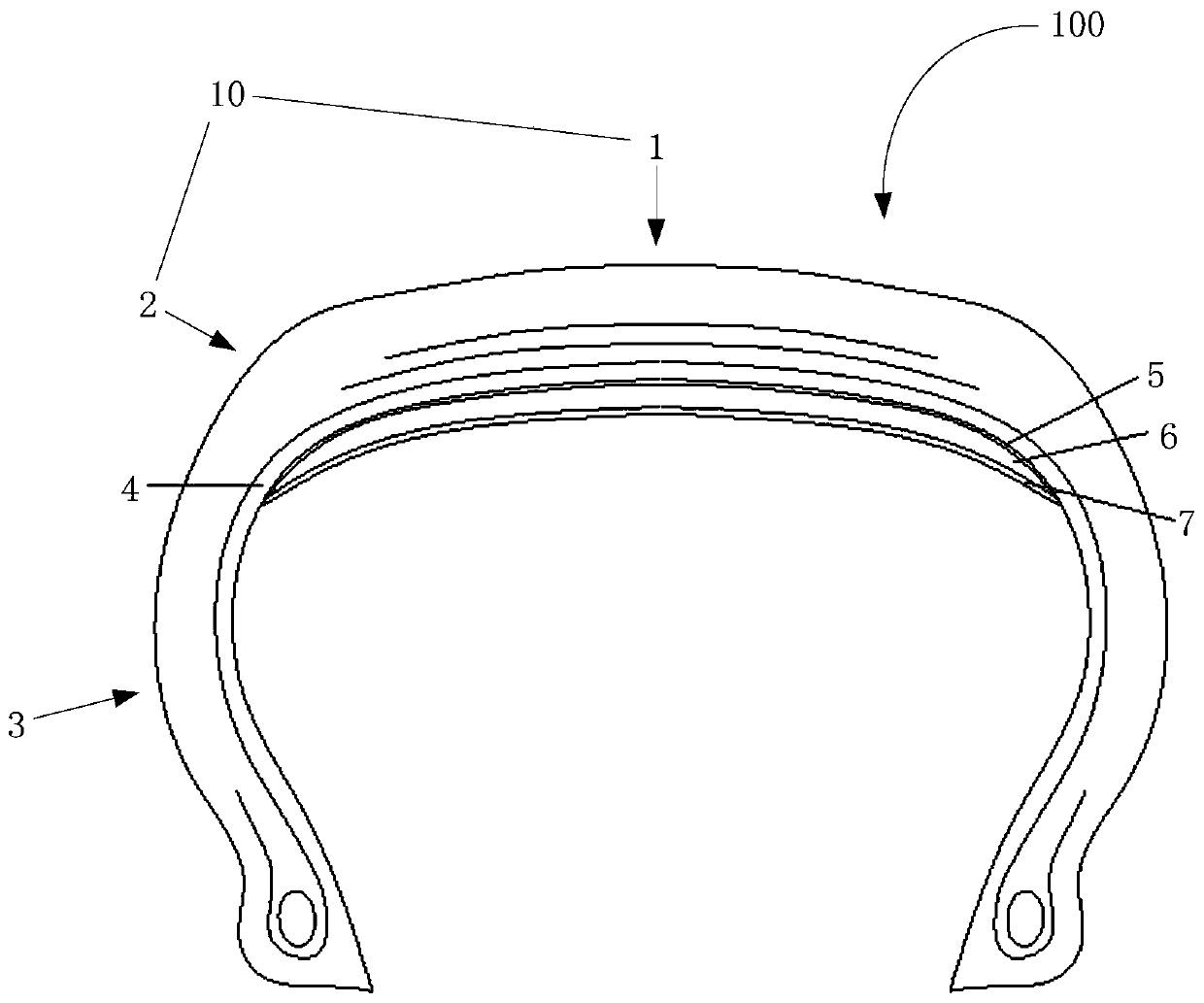

All-weather all-season tire and preparation method thereof

An all-season tire and all-weather technology, which is applied to tire parts, reinforcement layers of pneumatic tires, vehicle components, etc., can solve the problems that the grip performance is not as good as that of snow tires, driving safety cannot be guaranteed, and tire noise is loud. Improve wear resistance, facilitate popularization and application, and avoid safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

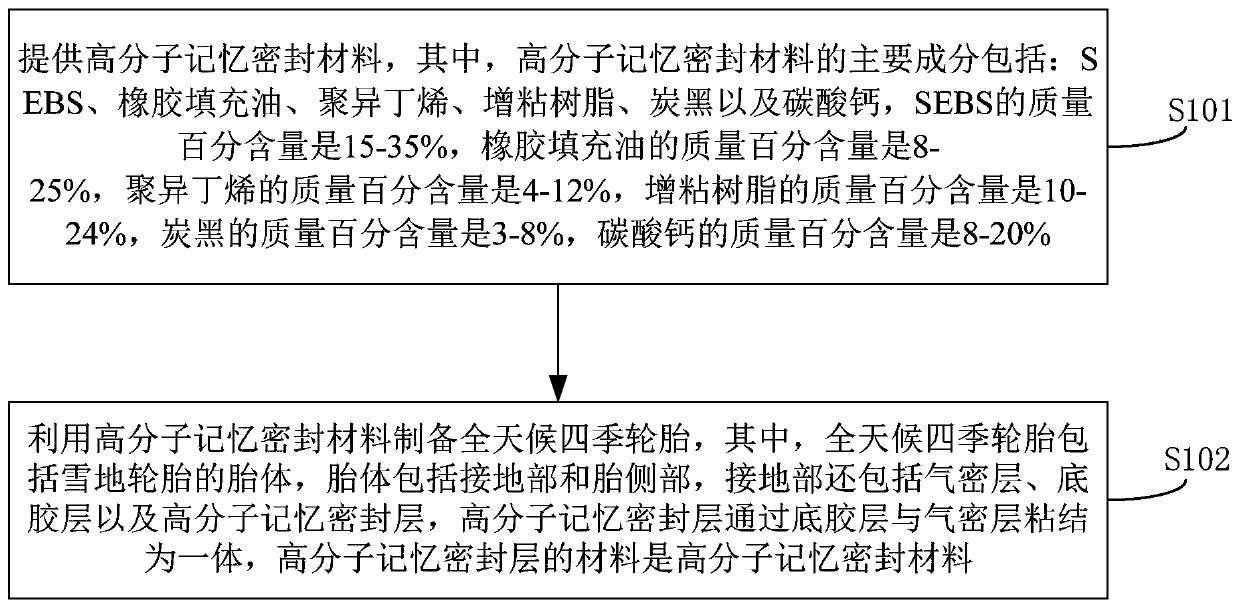

[0040] See also figure 2 , figure 2 It is a schematic flow diagram of an embodiment of the preparation method of all-weather four-season tires of the present invention. The preparation method of this embodiment can prepare the above-mentioned all-weather four-season tires. For detailed descriptions of related content, please refer to the above-mentioned all-weather four-season tires. . The method includes:

[0041] Step S101: Provide a polymer memory sealing material, where the main components of the polymer memory sealing material include: SEBS (styrene-ethylene-butylene-styrene block copolymer), rubber filling oil, polyisobutylene, and tackifying resin , Carbon black and calcium carbonate, the mass percentage of SEBS is 15-35%, the mass percentage of rubber extender is 8-25%, the mass percentage of polyisobutylene is 4-12%, the tackifying resin The mass percentage is 10-24%, the mass percentage of carbon black is 3-8%, and the mass percentage of calcium carbonate is 8-20%....

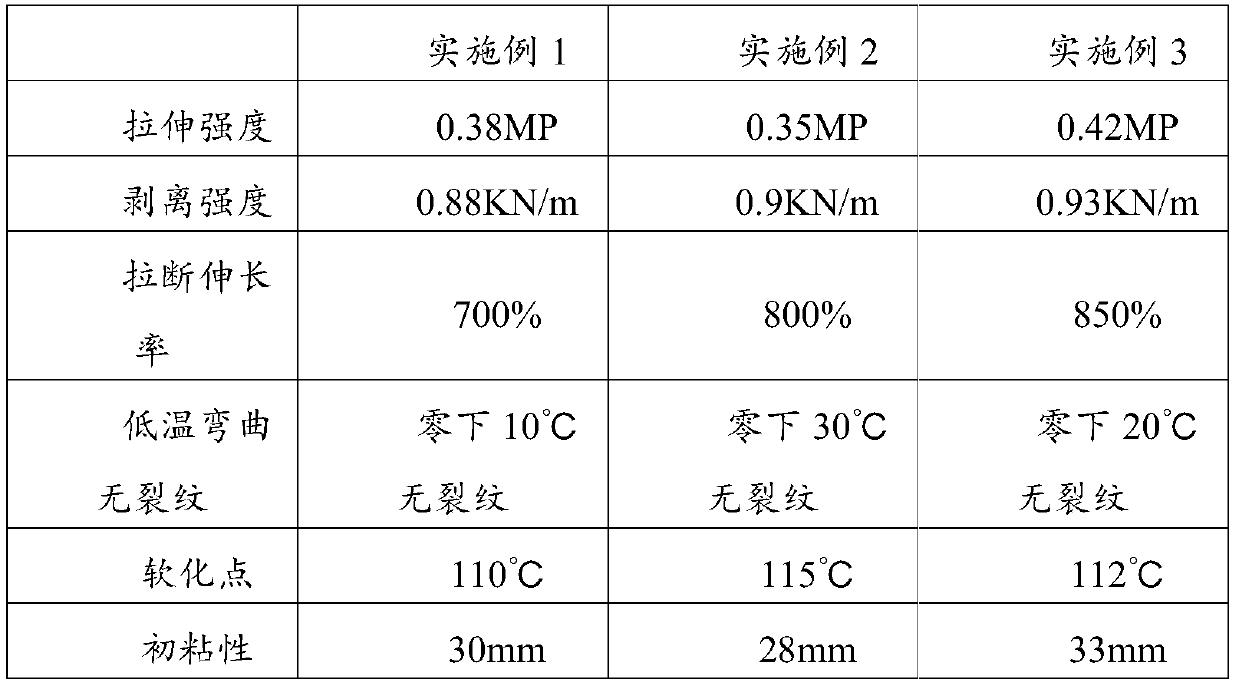

Embodiment 1

[0058] The mass percentages of each component of the polymer memory sealing material are: 27% SEBS, 15% rubber filler oil, 12% polyisobutylene, 22% tackifying resin, 6% carbon black, 18% carbonic acid calcium.

Embodiment 2

[0060] The mass percentage of each component of the polymer memory sealing material is: 30% SEBS, 20% rubber filler oil, 10% polyisobutylene, 20% tackifying resin, 5% carbon black, 15% carbonic acid calcium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com