A kind of food-grade water-soluble dry anti-wear chain road lubricant and preparation method thereof

A food-grade, water-soluble technology, used in lubricating compositions, additives, petroleum industry, etc., can solve the problems of chain wear, affecting the lubricating effect of lubricants and storage time, etc., to improve stability, eliminate food safety hazards, and improve The effect of lubrication and anti-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

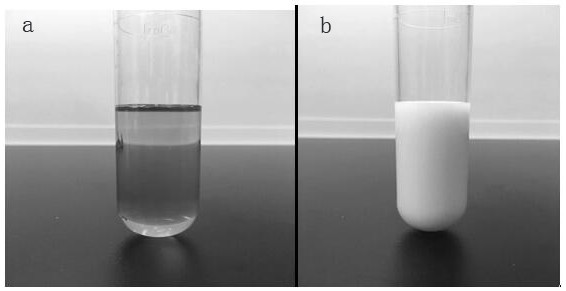

Image

Examples

Embodiment Construction

[0019] The following specific examples further illustrate the present invention, so that those skilled in the art can better understand the present invention and implement it, but the given examples are not intended to limit the present invention.

[0020] The water-soluble food-grade dry chain lubricant of the present invention is calculated according to weight percentage, selects an appropriate amount of components, first adds glucose powder pentahydroxyhexanal to deionized water and stirs evenly, then adds soybean lecithin powder into the solution to fully Stir and moisten, until there are no visible lumps in the solution, add surfactant to the above solution and continue to stir until the solution is completely clear and transparent; finally add antioxidant, bactericide, defoamer and stir until completely dissolved .

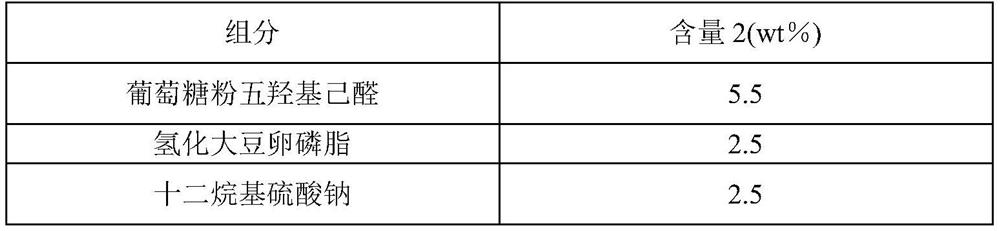

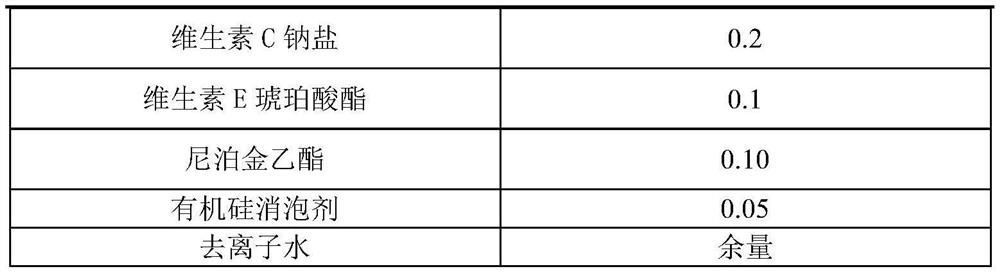

[0021] See Table 7 for the component contents (Table 1-6) and performance evaluation data of Examples 1-6. Each component can be obtained in the form of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com