A kind of variable thickness composite material stator blade and its forming method

A technology of composite materials and stator blades, which is applied in the integral molding of variable thickness stator blades, variable thickness composite material stator blades and their forming fields, and can solve the problem that cannot meet the needs of large variable thickness, high rigidity, high strength, and comprehensive performance of aeroengine stators. Blades and other issues, to achieve economic benefits and forward-looking outstanding, obvious technical advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

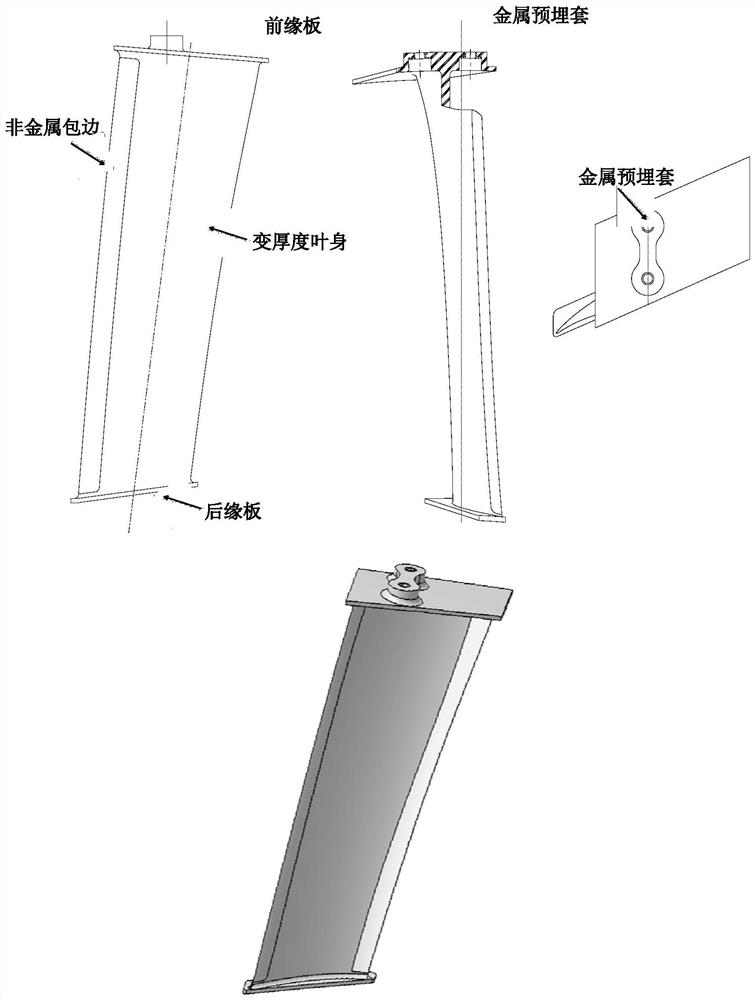

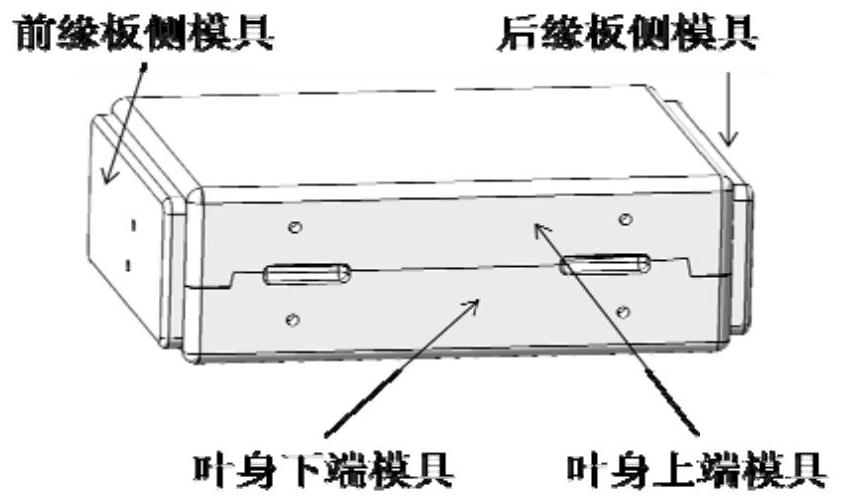

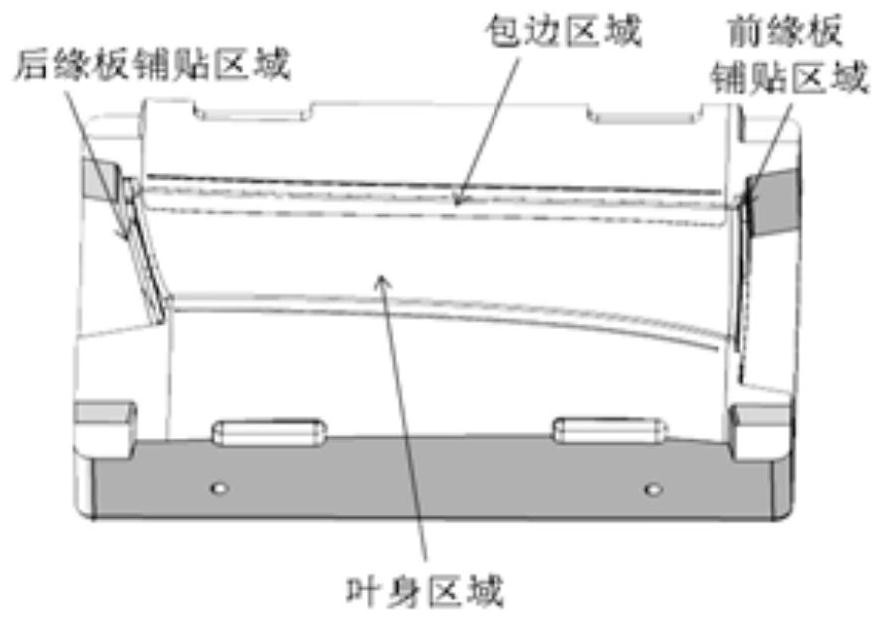

[0053] The variable-thickness composite stator blade described in the embodiment of the present invention includes a leading edge plate, a variable-thickness blade body, and a trailing edge plate, and the variable-thickness blade body is located between the leading edge plate and the trailing edge plate, and the leading edge plate, The variable-thickness blade body and the trailing edge plate are made of the same composite material and the three are integrally formed, and the windward surface of the blade body is protected by wear-resistant non-metal edging. The reinforcement used for the manufacturing materials of the leading edge plate, the blade body and the trailing edge plate is T800 carbon fiber twill fabric, the resin matrix is toughened 603 ring epoxy resin, and the prepared prepreg grade is T800-6k-XW / 603, The thickness of the single layer after curing is 0.2mm.

[0054] The thickness of the blade body from the root of the leading edge plate to the root of the trail...

Embodiment 2

[0066] The variable-thickness composite stator blade described in the embodiment of the present invention includes a leading edge plate, a variable-thickness blade body, and a trailing edge plate, and the variable-thickness blade body is located between the leading edge plate and the trailing edge plate, and the leading edge plate, The variable-thickness blade body and the trailing edge plate are made of the same composite material and the three are integrally formed, and the windward surface of the blade body is protected by wear-resistant non-metal edging. The reinforcement used in the manufacture of the leading edge plate, the blade body and the trailing edge plate is T800 carbon fiber twill fabric, the resin matrix is toughened 602 epoxy resin, and the prepared prepreg grade is T800-6k-XW / 602. The thickness of the single layer after curing is 0.2mm.

[0067] The thickness of the blade body from the root of the leading edge plate to the root of the trailing edge plate gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com