Wind power generation device

A wind power generation device and generator technology, applied in the electric power field, can solve the problems of high component installation cost, long recovery period and high transportation cost, and achieve the effects of less installation difficulty, low installation cost and low transportation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the drawings and specific embodiments:

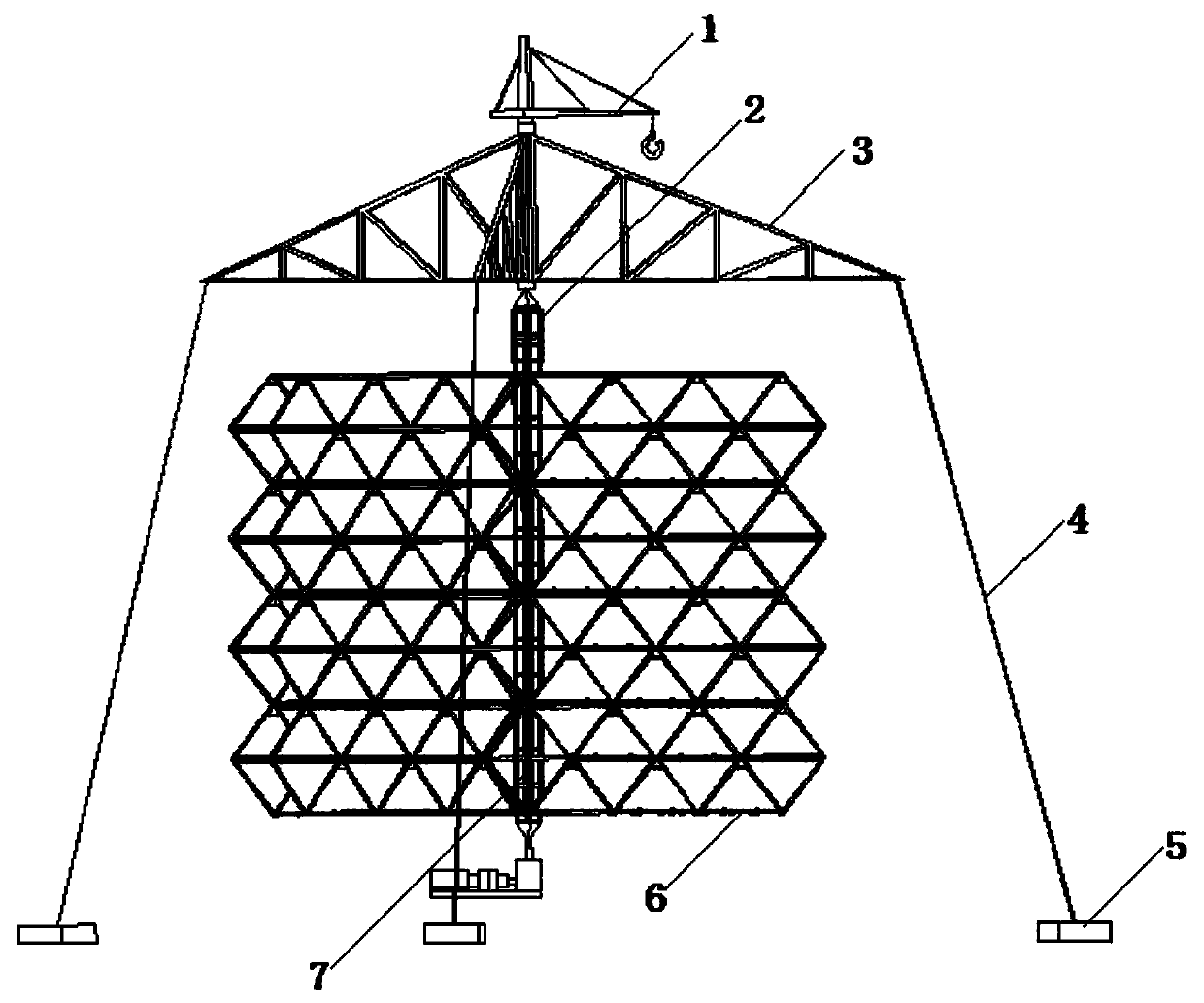

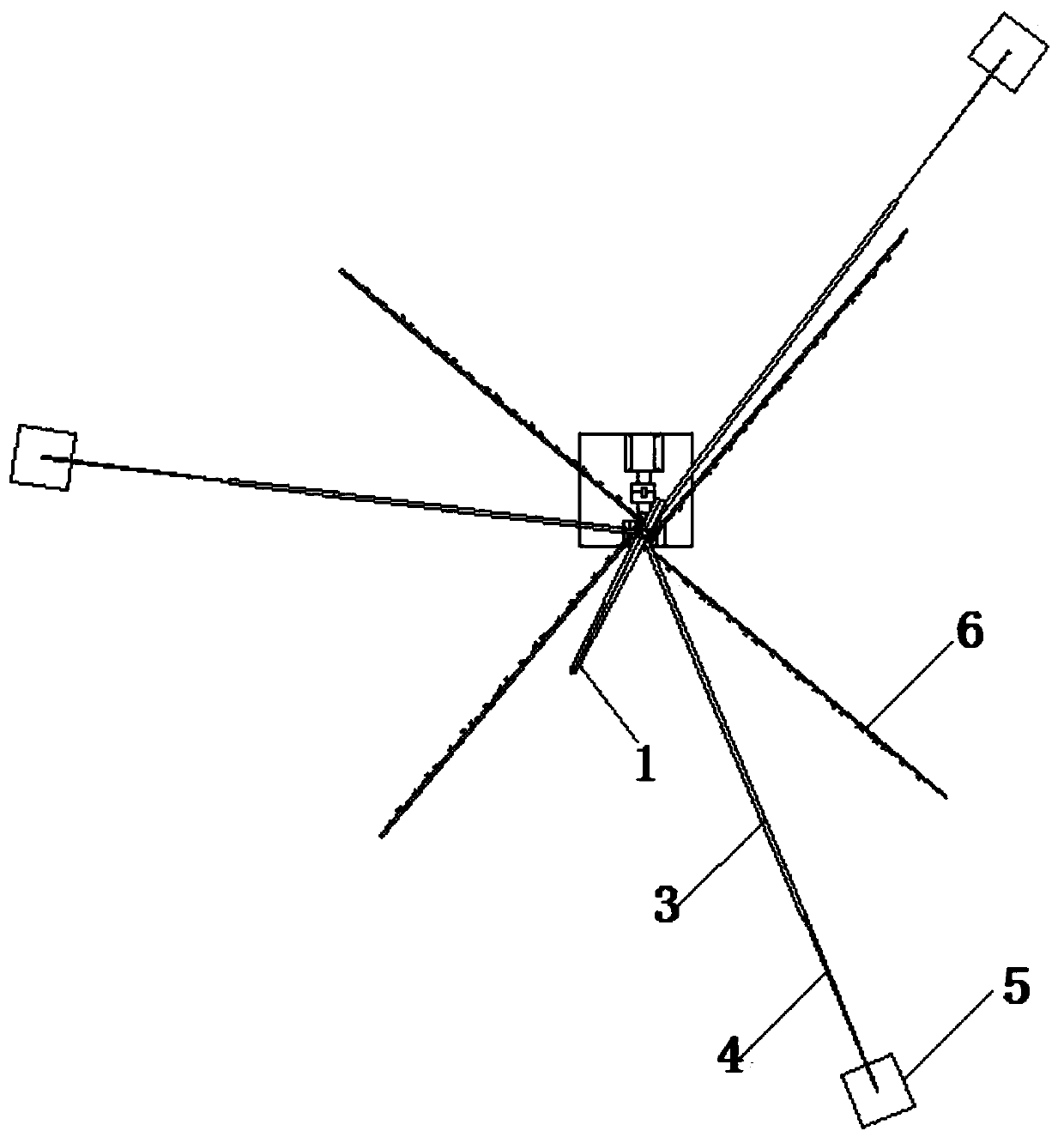

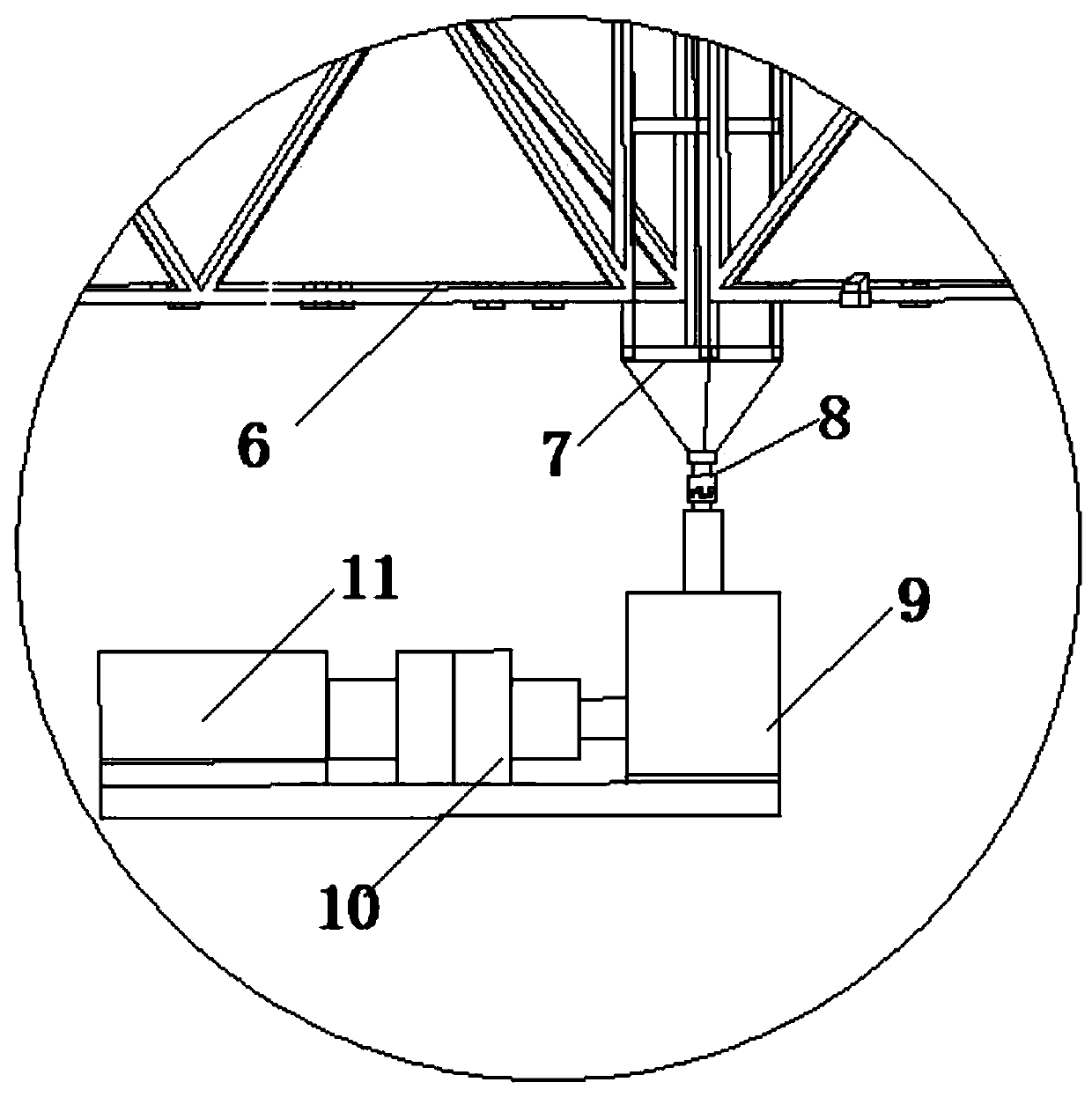

[0044] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the wind power generation device of the present invention includes a generator 11, a right-angle transmission gearbox 9, a first shaft coupling 8, a main shaft 7, a choke plate 6, a second shaft coupling 16 and a fixing frame. The generator 11 is fixedly connected to the ground. The right-angle transmission gearbox 9 is fixed on the ground, and the right-angle transmission gearbox 9 is drivingly connected with the input shaft of the generator 11. The first shaft coupling 8 is in transmission connection with the right-angle transmission gearbox 9. The main shaft 7 has a square shape or a triangle shape, and both ends are tapered. The main shaft 7 is made up of at least two sections fixedly connected by bolts. The main shaft 7 is preferably made of angle steel fixed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap