Heat pipe type heat exchanger

A heat exchanger and heat pipe technology, applied in the field of heat exchanger devices, can solve the problems of uneven fuel combustion and heat exchange, small heat exchange coefficient between gas and high temperature heat exchanger, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

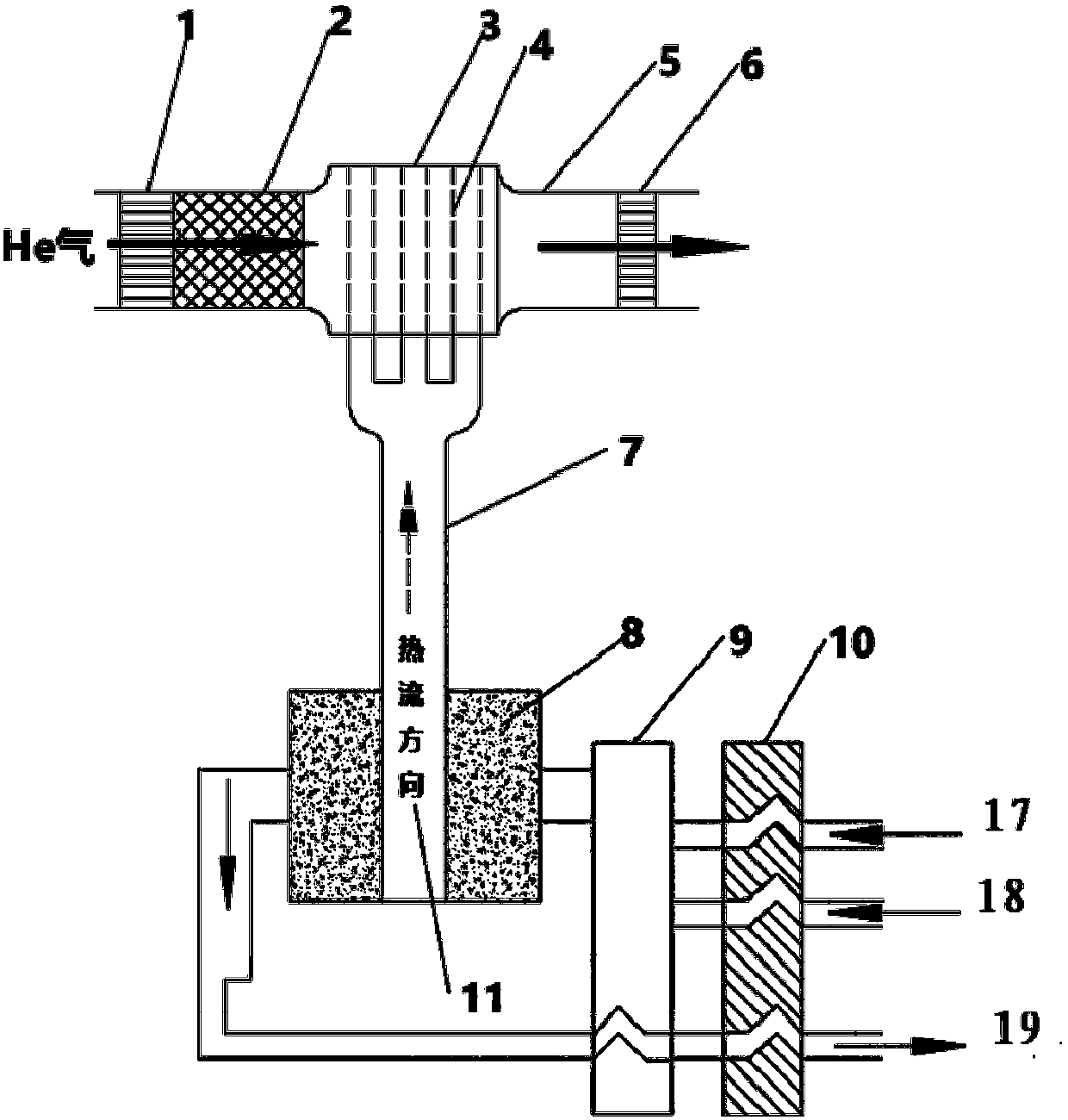

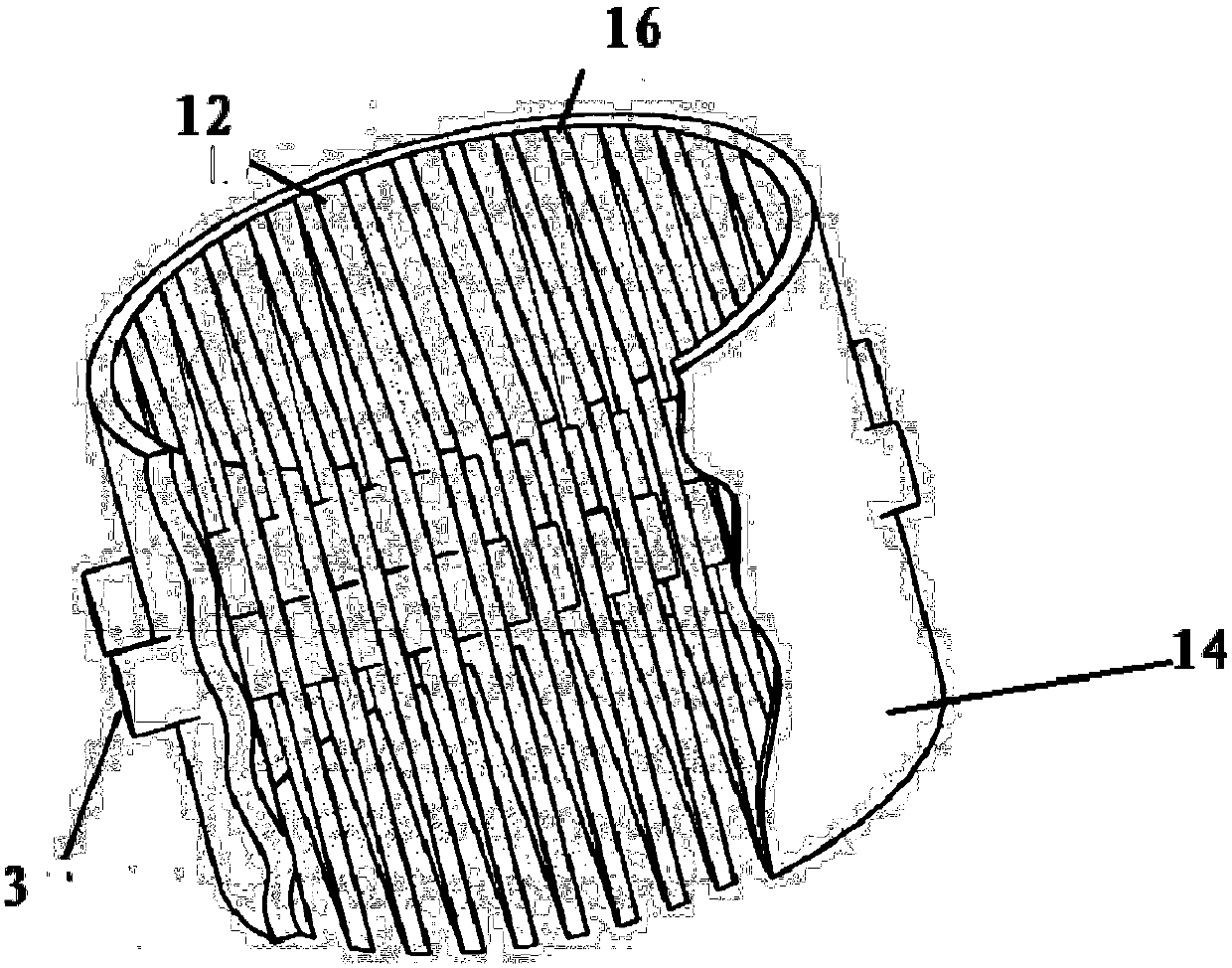

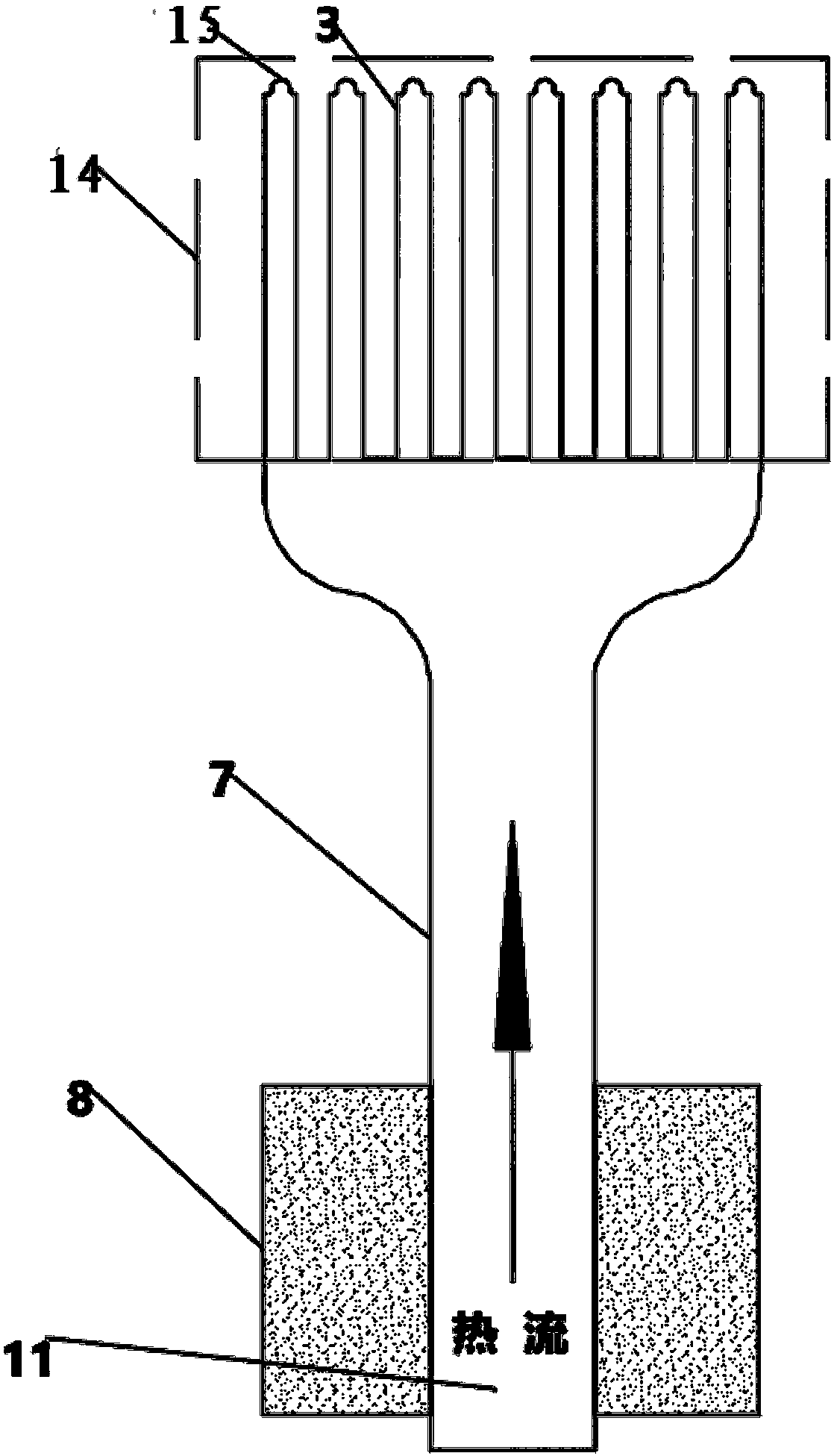

[0059] figure 2 It is a structural schematic diagram of a high temperature heat exchanger according to a preferred embodiment of the present invention,

[0060] image 3 It is a schematic diagram of an integrated heat pipe according to a preferred embodiment of the present invention, such as figure 2 and image 3 As shown, the structure of this embodiment adopts a linear integrated heat pipe, which mainly includes a heat pipe condensation section 3, a heat pipe insulation section 7, a porous medium material 8, a heat pipe evaporation section 11, a high-temperature heat exchanger shell 14 and a gas collection bubble 15 compositions. This structure unifies the traditional multiple heat pipes discharged in parallel into a linear one-piece fork row structure. The heat pipes of this structure share the same heat pipe evaporation section 11, heat pipe insulation section 7 and heat pipe condensation section 3 respectively. Structures such as the heat-absorbing core in the conde...

Embodiment 2

[0063] Figure 4 It is a structural schematic diagram of a high temperature heat exchanger according to a preferred embodiment of the present invention,

[0064] Figure 5 It is a schematic diagram of an integrated heat pipe according to a preferred embodiment of the present invention, such as Figure 4 and Figure 5 As shown, the structure of this embodiment adopts an L-shaped integrated heat pipe, which consists of a heat pipe condensation section 3, a heat pipe insulation section 7, a porous medium material 8, a heat pipe evaporation section 11, a high-temperature heat exchanger shell 14, and a gas collection bubble 15 Composed of gas working medium heat exchange tubes 13. This structure respectively shares the same heat pipe evaporation section 11 , heat pipe insulation section 7 and heat pipe condensation section 3 . On the condensing section 3 of the heat pipe, the gas working medium heat exchange tubes 13 vertically inserted into the equidistant fork row, and the ma...

Embodiment 3

[0066] Figure 6 It is a schematic diagram of an integrated heat pipe according to a preferred embodiment of the present invention, such as Figure 6 As shown, the structure of this embodiment adopts an annular integrated heat pipe. The liquid working medium passes through the heat pipe evaporation section 11 after burning in the porous medium in the burner, and rises along the heat pipe adiabatic section 7 to enter the high-temperature heat exchanger of the thermoacoustic engine, and flows back to the burner along the annular heat pipe after condensing in the high-temperature heat exchanger , forming a flow loop. The inert gas working medium of the thermoacoustic engine flows through the high-temperature heat exchanger, and exchanges heat with the gaseous sodium-potassium alloy through the tube wall. When in use, the annular heat pipe obtains heat from a high-temperature heat source. In the condensation section 3 of the heat pipe, the steam in the heat pipe condenses and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com