Method and system for measuring dynamic electromagnetic loss of giant magnetostrictive transducer

A giant magnetostriction and electromagnetic loss technology, which is applied in the direction of measuring devices, measuring electrical variables, measuring magnetic variables, etc., can solve the problems of inability to calculate the electromagnetic loss of the transducer in real time, low energy conversion efficiency, and limited frequency range of measurement, etc. problem, to achieve fast, more accurate and more effective measurement, simple and direct measurement method, and convenient data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

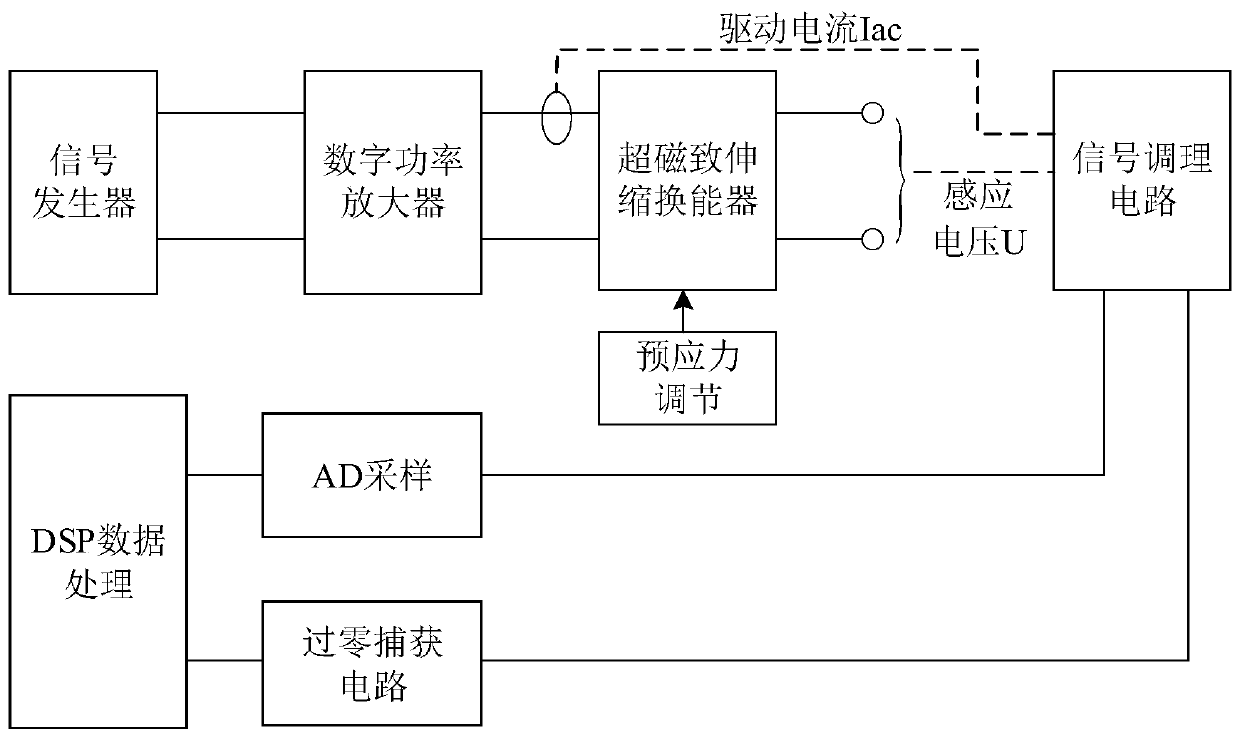

[0028] The present invention comprises the following steps:

[0029] 1) The signal generator and digital power amplifier form a dynamic magnetic field drive unit, which generates a drive signal with adjustable amplitude and frequency. The elongation of the giant magnetostrictive material changes under the drive magnetic field, thereby generating vibration to drive the entire transducer to vibrate. ;

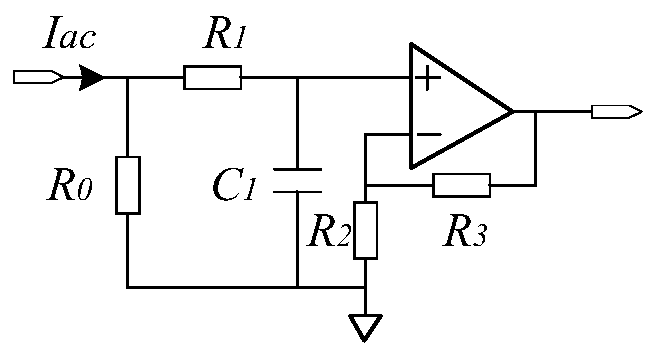

[0030] 2) Voltage and current sensors form a signal measurement unit, which respectively detects the driving current signal Iac of the driving coil of the giant magnetostrictive transducer and the induced voltage signal U of the detection coil. The conditioning circuit converts the driving current signal Iac sent by the sensor and the induced voltage signal U of the detection coil into a voltage signal within ±10V, which is converted into a digital signal by the built-in AD sampling of the DSP. The DSP obtains the maximum value of the drive current Iac signal and the induced vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com