Automatic ore drawing experiment method and system based on image recognition

An image recognition and experimental method technology, applied in the field of automatic ore drawing experimental methods and systems based on image recognition, can solve the problems of time-consuming, laborious, discontinuous, and unfavorable research work, and achieve the effect of realizing process automation and accurate shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

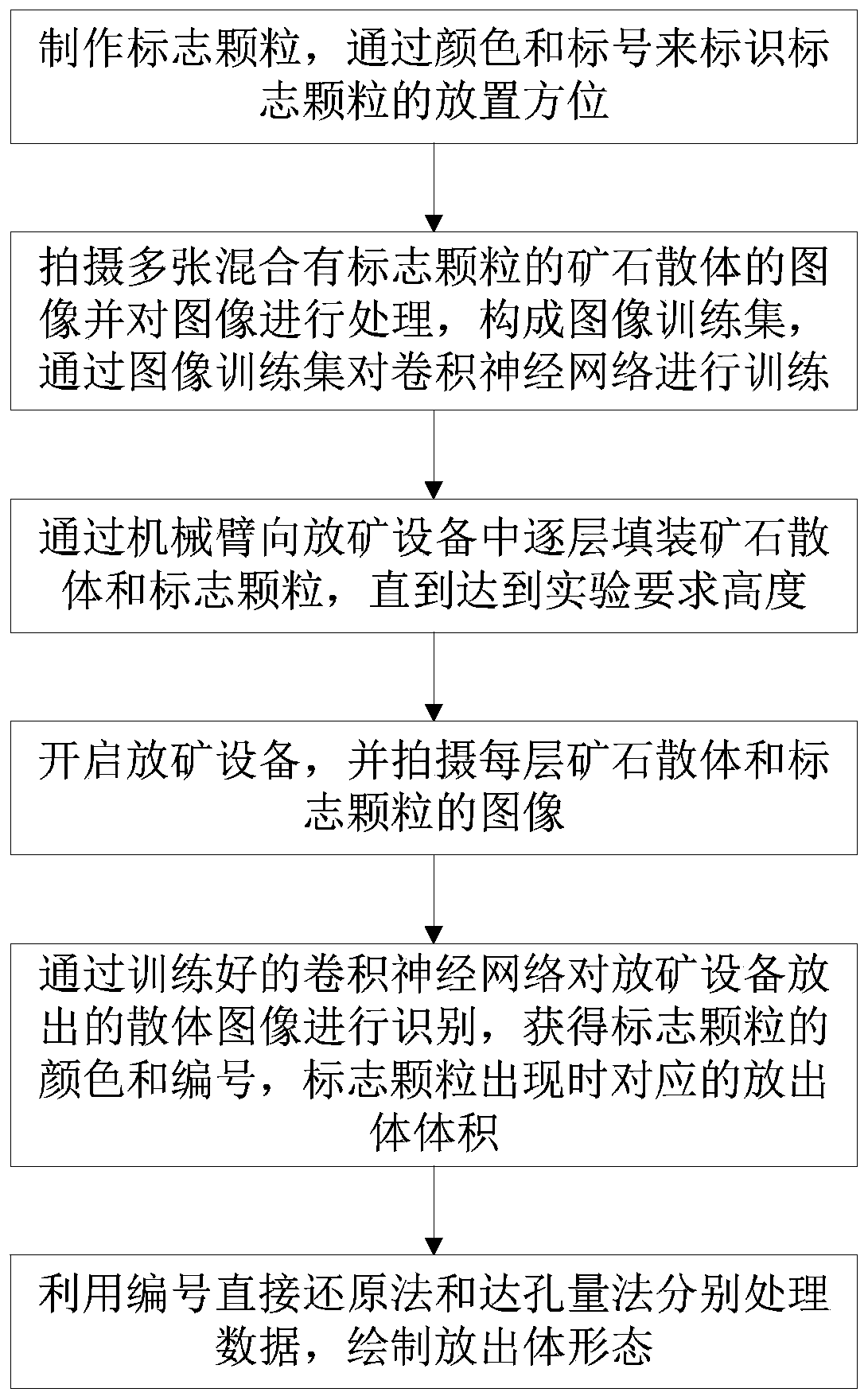

[0064] Such as figure 1 Shown, a kind of automatic ore-drawing experimental method based on image recognition of the present invention comprises the following steps:

[0065] Step 1: Make the logo particles, and identify the placement orientation of the logo particles by color and label. The step 1 is specifically:

[0066] Step 1.1: Dye the logo particles into different colors to indicate the difference in height, and then dry them;

[0067] Step 1.2: Mark a two-digit number on the dyed and dried marker particles, the first digit indicates the direction angle, and the second digit indicates the distance between the position of the marker particle and the center.

[0068] In order to improve the accuracy of image recognition, the produced logo particles should be able to accurately identify the color and number when placed at any angle. For this reason, when making logo particles, try to select particles with regular shapes and carry out in multiple directions. number for ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com