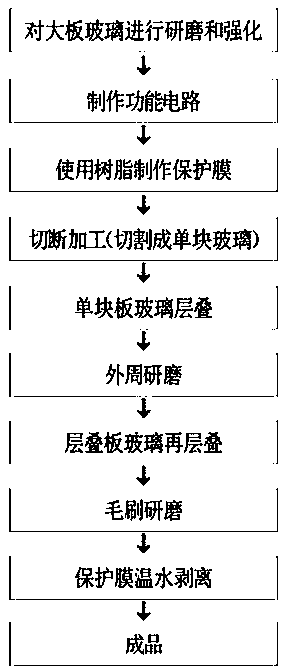

Method for processing plate glass provided with functional circuit

A processing method and functional circuit technology, applied in the direction of circuit substrate materials, printed circuits, printed circuit manufacturing, etc., can solve problems such as unstable physical strength of products, and achieve the effects of saving manpower, avoiding corrosion, and rapid peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the following specific examples are only used to explain the present invention, but not to limit the present invention.

[0034] The cover glass used for electronic products is originally ordinary glass, and its surface has been ground and polished to meet the requirements of optical mirrors, but the surface is very fragile. Since the touch screen panel glass is relatively thin, the surface flatness requirements are high, and forming is difficult, the manufacturing process is much more complicated than that of ordinary flat glass. Up to polishing and other processes, it is very easy to cause a certain degree of scratches on the glass substrate in the machine or other operations, and the scratch rate is generally above 42%, which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com