Reactor

A technology for reactors and changing parts, applied in the field of reactors, can solve problems such as difficulty in ensuring safety, and achieve the effects of avoiding temperature drop, reducing the amount of addition, and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

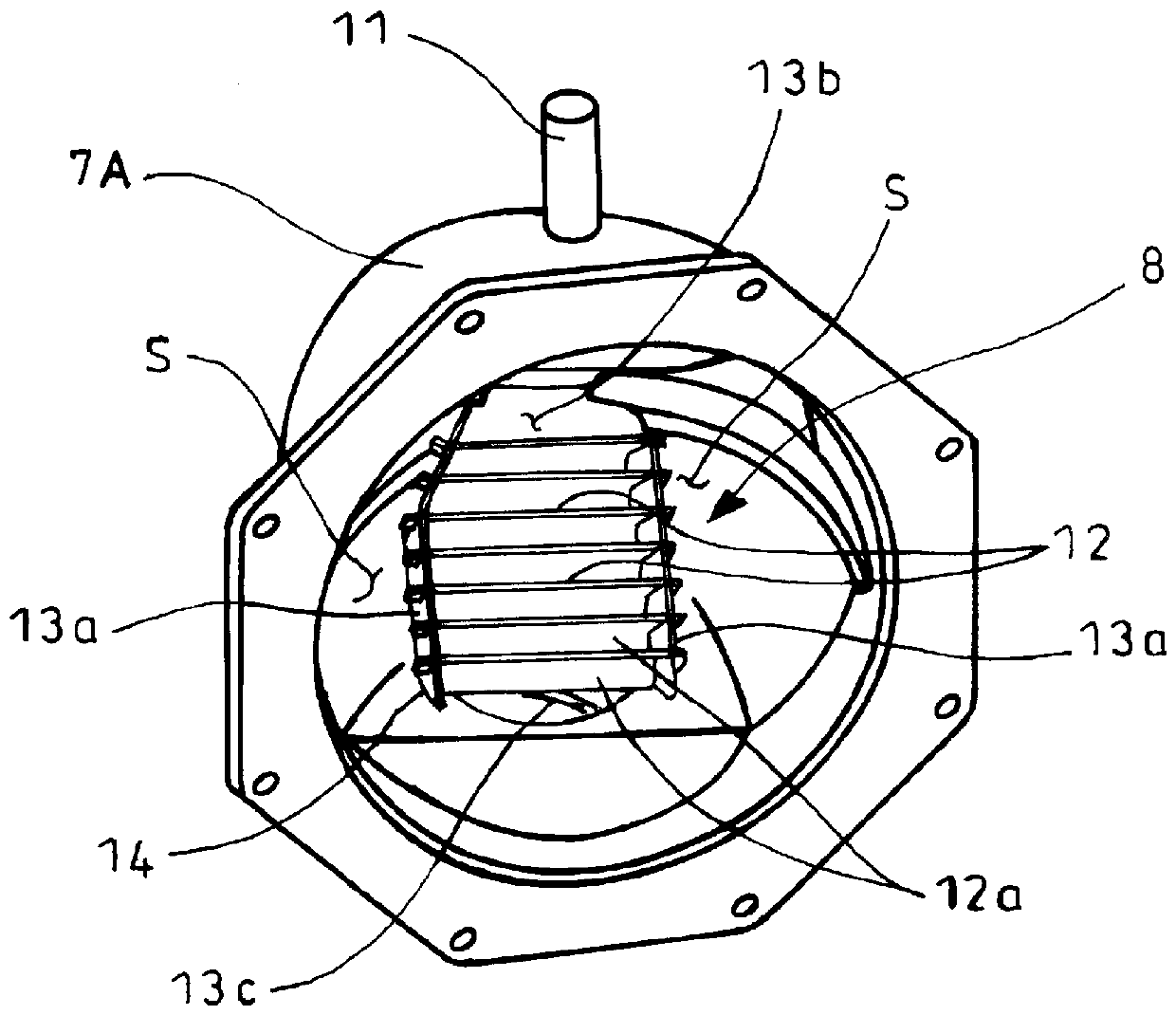

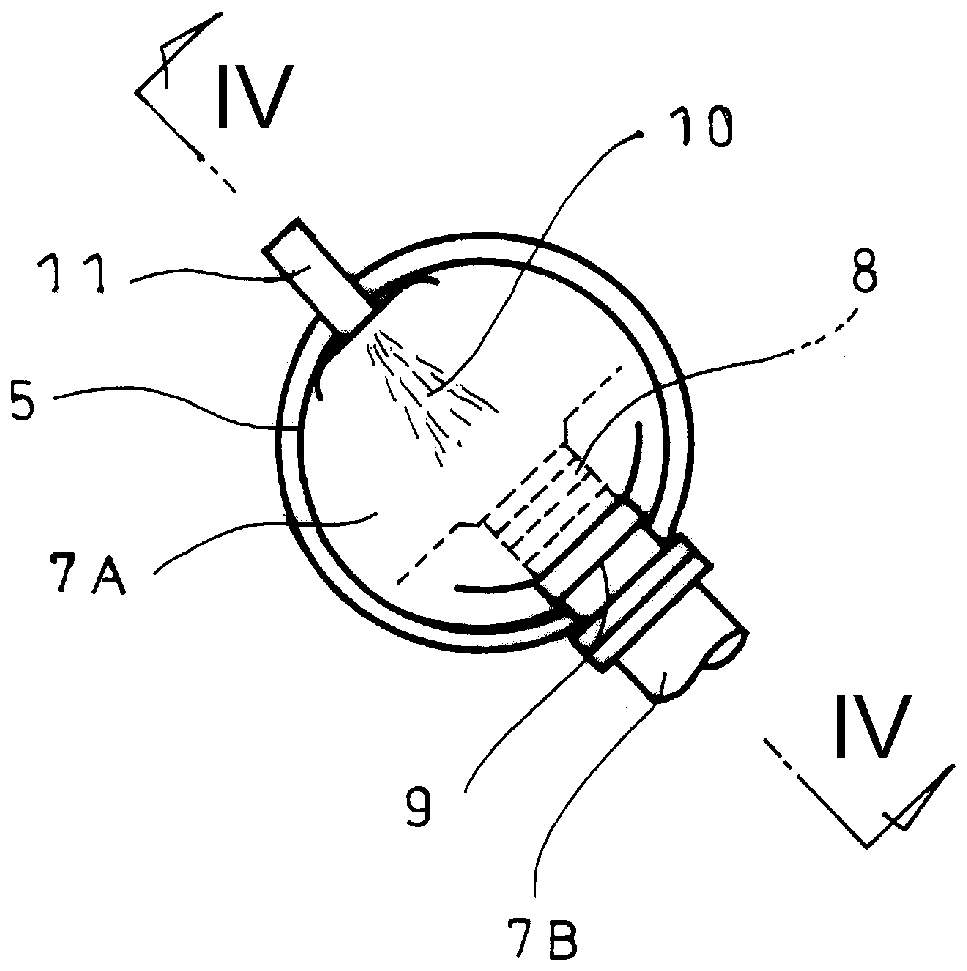

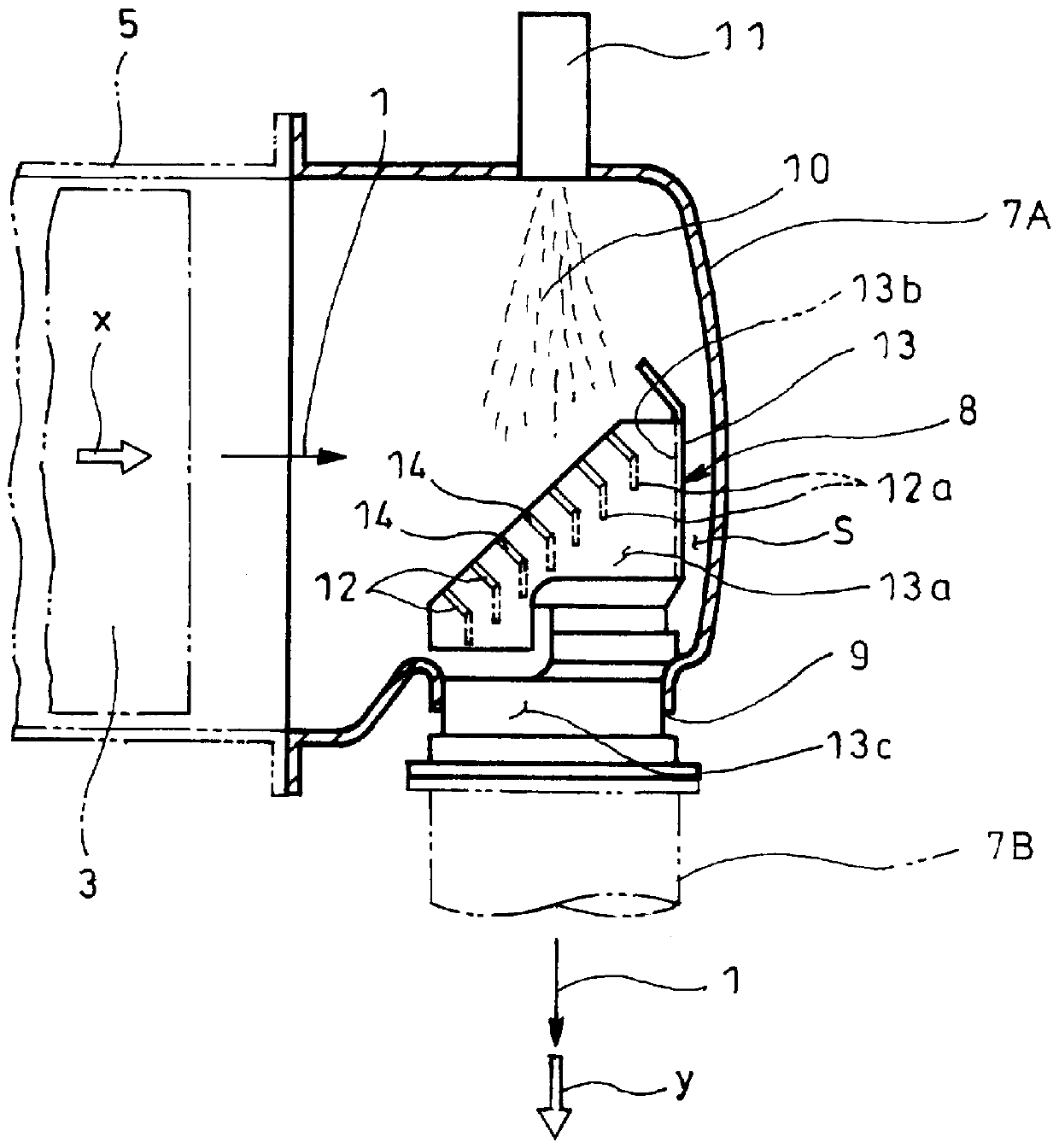

[0028] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0029] figure 2 It is a figure showing one embodiment of the present invention. In this embodiment, an example of application to an exhaust gas purification device as described in detail below is shown, more specifically, an exhaust gas purification system equipped with a communication flow path 7 The device is an example in which the reactor 8 is installed at the flow changing part at the most upstream part of the communication flow path 7 as an application site. On the way, the particulate filter 3 that traps particulates in the exhaust gas 1 and the selective reduction catalyst 4 are arranged in parallel by housings 5 and 6, respectively. 4 On the downstream side of the particulate filter 3, it has the property of selectively reacting NOx and ammonia even under the coexistence of oxygen; The gas 1 is turned back in the opposite direction and introduced to the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com