Plant beverage concentrated liquid and making method thereof

A plant beverage and concentrate technology, which is applied to the field of plant beverage concentrate and its preparation, can solve the problems of large loss of aroma of the extract, affecting the quality of the finished product, and loss of effective components, etc., so as to ensure quality stability and high quality stability. , the effect of fewer types of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

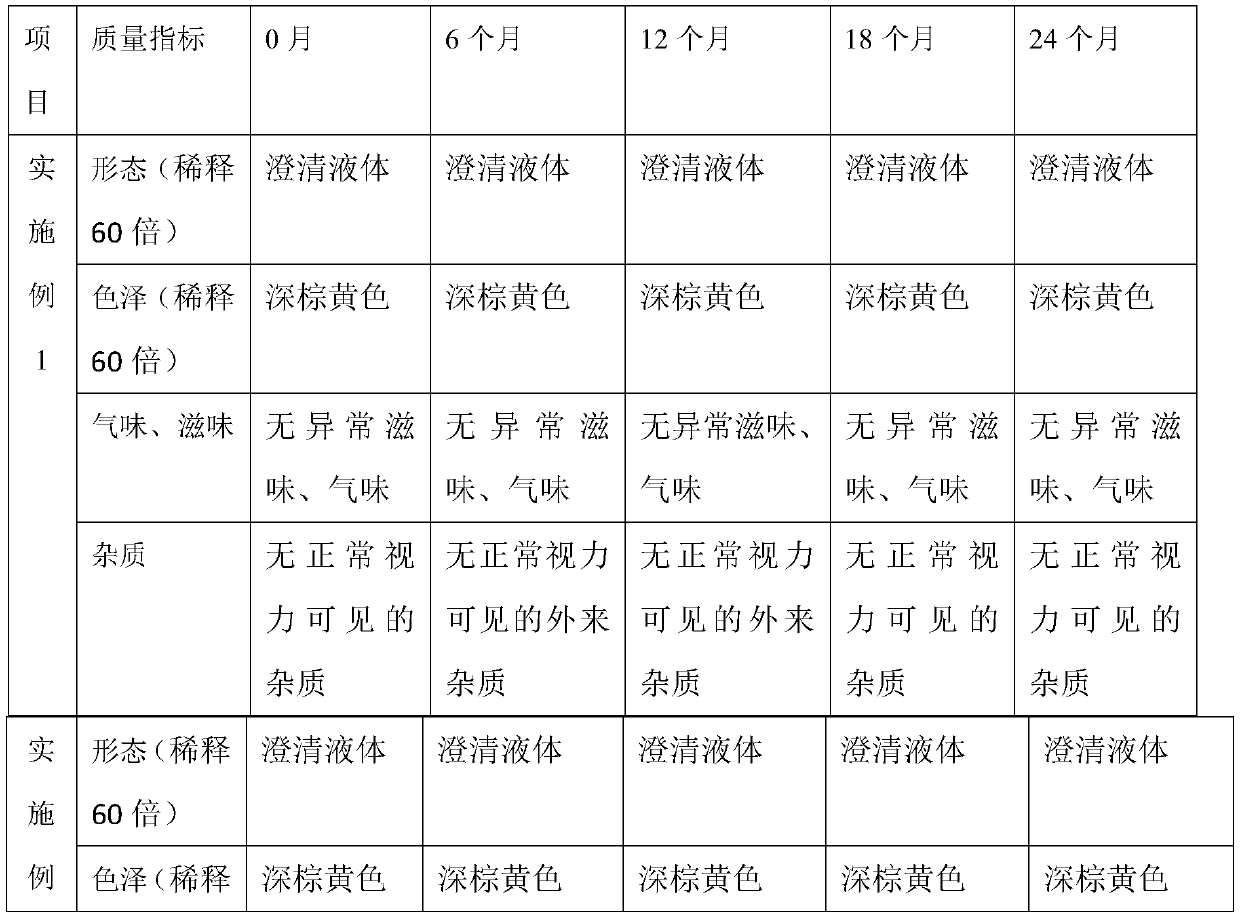

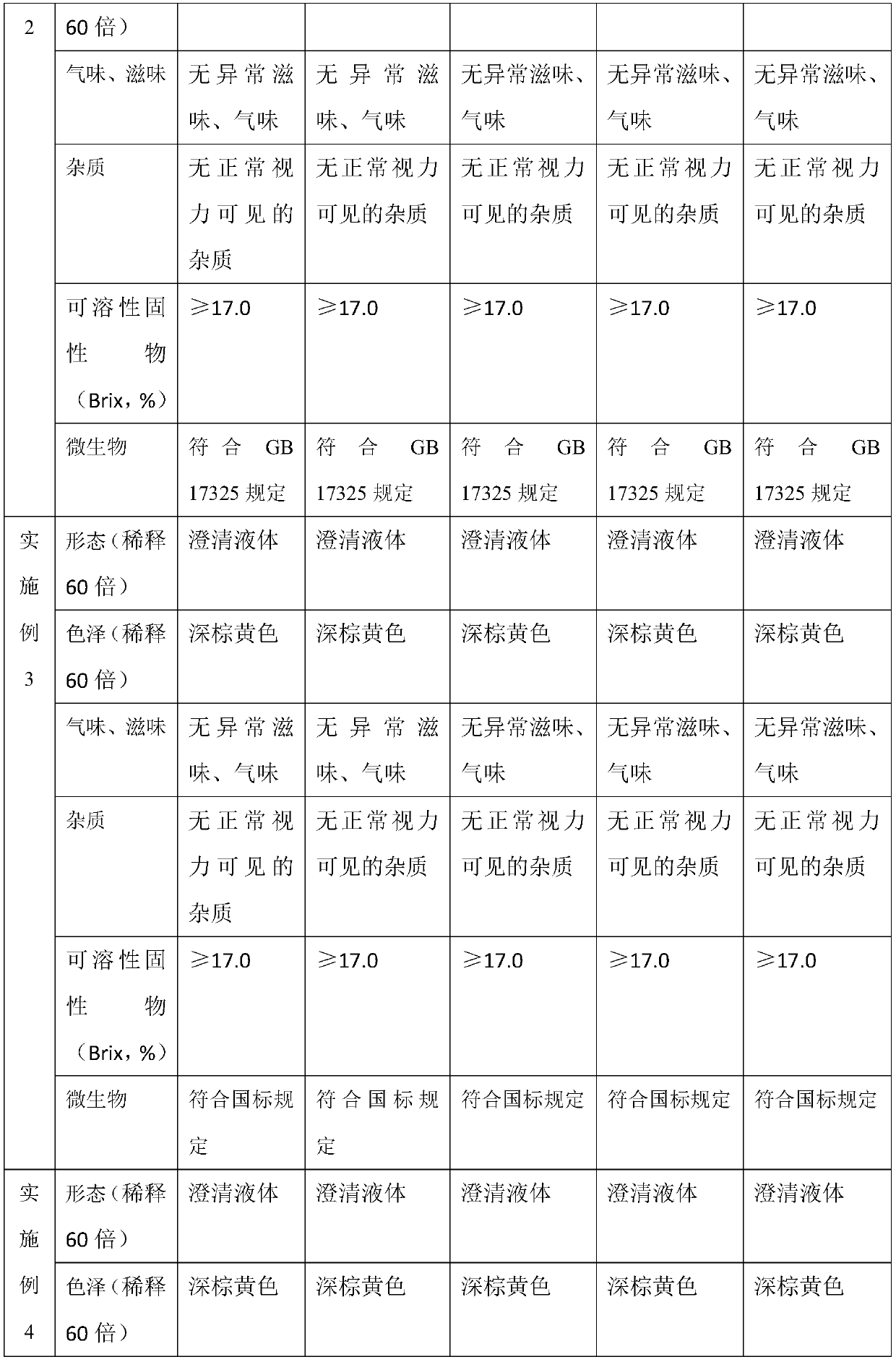

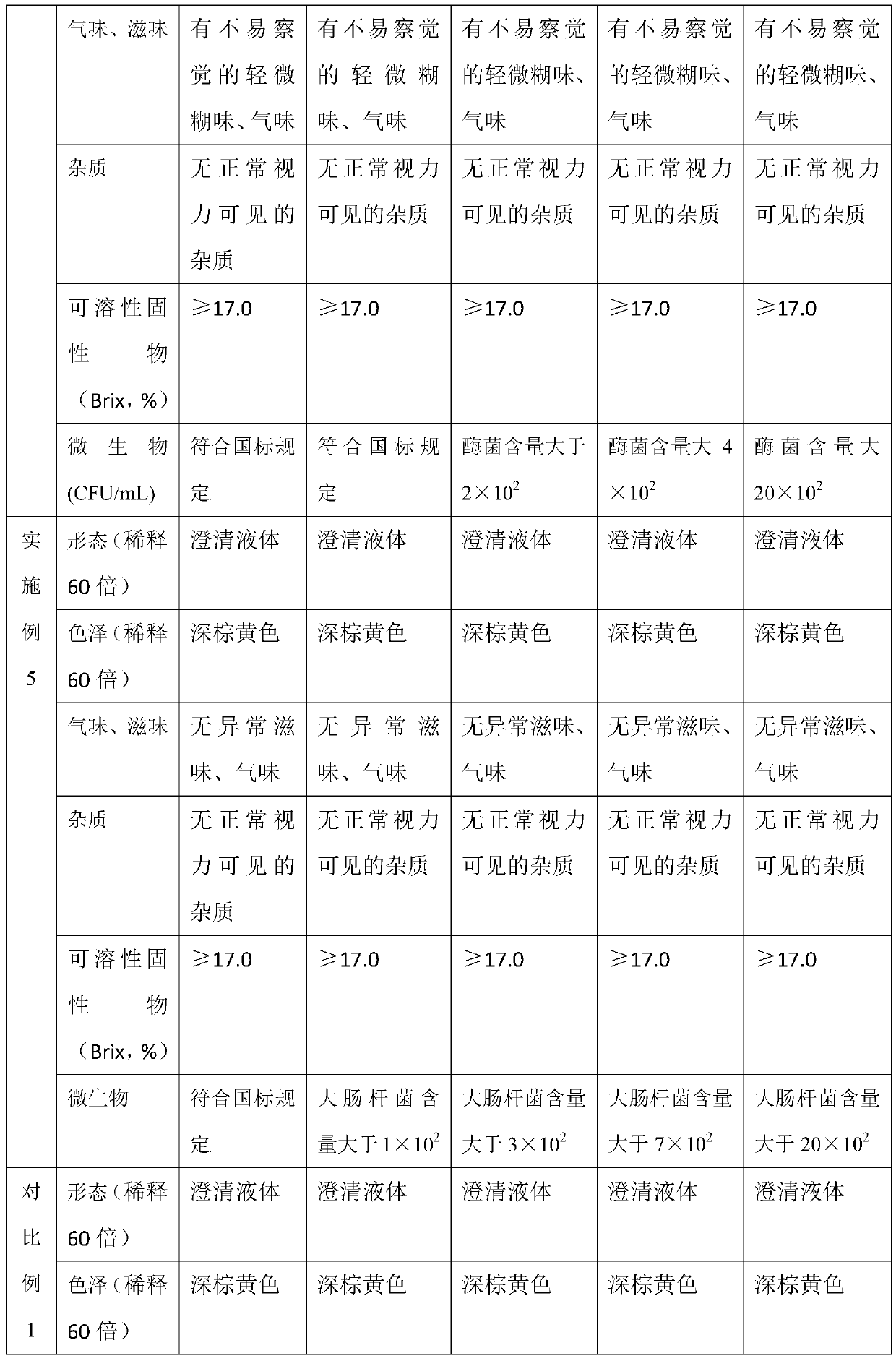

Examples

Embodiment 1

[0052] A plant beverage concentrate, which is made from the following raw materials in parts by weight:

[0053] Prunella vulgaris 2.0 parts;

[0054] 9.08 parts of grass jelly;

[0055] 2.0 parts of licorice;

[0056] Honeysuckle 2.0 parts;

[0057] Frangipani 2.0 parts;

[0058] Chrysanthemum 2.0 parts;

[0059] 2.0 parts of mulberry leaves;

[0060] Cloth leaves 2.0 parts;

[0061] 2.0 parts of Momordica grosvenori; and the water that just soaks and covers the amount of each raw material above.

[0062] The preparation method of plant drink concentrate as mentioned above comprises the steps:

[0063] S1 Extraction: Put 80% of the selected and cleaned grass jelly into the extraction tank, then add Prunella vulgaris, mulberry leaves, cloth jasmine leaves, Luo Han Guo, licorice, honeysuckle, frangipani and chrysanthemum, and finally put in the remaining jelly grass, Add water until all raw materials are soaked, and extract at a constant temperature of 90°C for 60 minut...

Embodiment 2

[0070] A plant beverage concentrate, which is made from the following raw materials in parts by weight:

[0071] Prunella vulgaris 2.0 parts;

[0072] 9.08 parts of grass jelly;

[0073] 2.0 parts of licorice;

[0074] Honeysuckle 2.0 parts;

[0075] Frangipani 2.0 parts;

[0076] Chrysanthemum 2.0 parts;

[0077] 15.0 parts of mulberry leaves;

[0078] Cloth leaves 2.0 parts;

[0079] Luo Han Guo 2.0 parts;

[0080] The preparation method of plant drink concentrate as mentioned above comprises the steps:

[0081] S1 Extraction: Put 80% of the selected and cleaned grass jelly into the extraction tank, then add Prunella vulgaris, mulberry leaves, cloth jasmine leaves, Luo Han Guo, licorice, honeysuckle, frangipani and chrysanthemum, and finally put in the remaining jelly grass, Add water until all raw materials are soaked, and extract at a constant temperature of 90°C for 60 minutes;

[0082] S2 Filtration: Centrifuge the extract obtained in step S1 to obtain the feed ...

Embodiment 3

[0089] A plant beverage concentrate, which is made from the following raw materials in parts by weight:

[0090] Prunella vulgaris 2.0 parts;

[0091] 9.08 parts of grass jelly;

[0092] 2.0 parts of licorice;

[0093] Honeysuckle 2.0 parts;

[0094] Frangipani 2.0 parts;

[0095] Chrysanthemum 2.0 parts;

[0096] 2.0 parts of mulberry leaves;

[0097] Cloth leaves 2.0 parts;

[0098] 10.0 parts of Momordica grosvenori; and the water that just soaks and covers the amount of each raw material above.

[0099] The preparation method of plant drink concentrate as mentioned above comprises the steps:

[0100] S1 Extraction: Put 80% of the selected and cleaned grass jelly into the extraction tank, then add Prunella vulgaris, mulberry leaves, cloth jasmine leaves, Luo Han Guo, licorice, honeysuckle, frangipani and chrysanthemum, and finally put in the remaining jelly grass, Add water until all raw materials are soaked, and extract at a constant temperature of 90°C for 60 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com