Calibration method of capacity of pipettor

A calibration method and pipette technology, applied in the field of pipettes, can solve problems such as errors, meet calibration requirements, reduce environmental conditions and personnel operation requirements, and improve measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

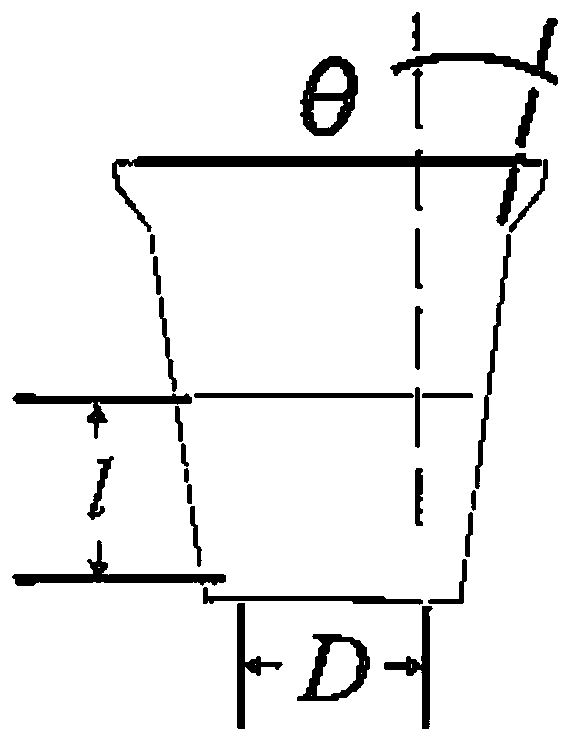

[0037] This embodiment provides a method for calibrating the capacity of a pipette, comprising the following steps:

[0038] S1, preparation of chromogenic solution;

[0039] S2, pipette quantitative diluents to several colorimetric bottles;

[0040] S3. Pipette the chromogenic solution according to the proportion to prepare a series of standard solutions;

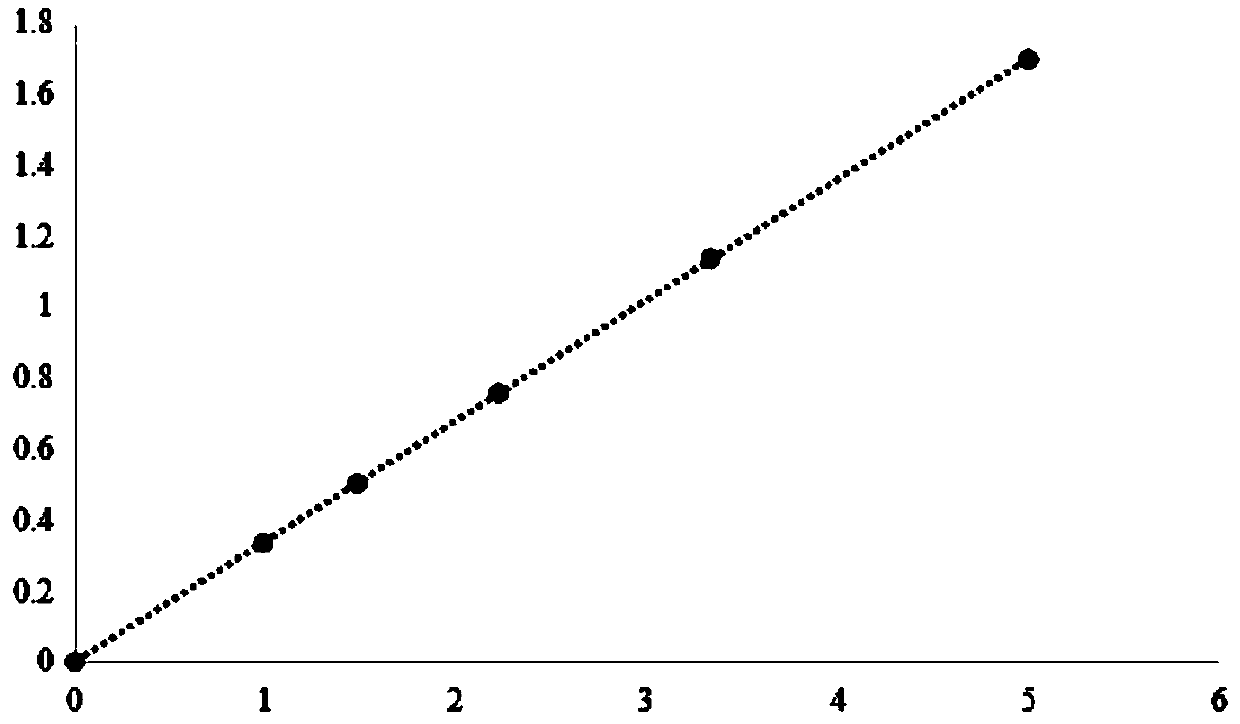

[0041] S4, using a spectrophotometer to measure the absorbance value of a series of standard solutions to obtain a standard working curve;

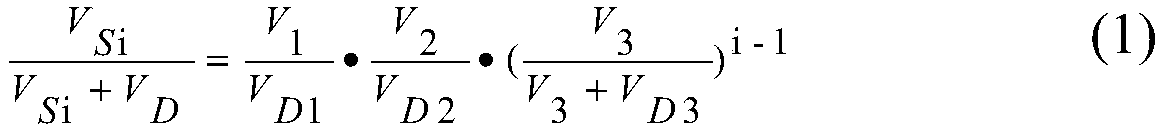

[0042] S5. Put the colorimetric bottle containing the diluent in step S2 into the spectrophotometer for zero adjustment; adjust the pipette to the capacity to be calibrated, pipette the color developing solution of the corresponding capacity, and add it to the colorimetric bottle Neutralize and shake well, measure the absorbance value, and calculate the capacity value and error at the capacity point to be calibrated according to the standard working curve;

[0043] S6. Repeat step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com