CPP protective film with good flatness

A flatness and protective film technology, applied to film/sheet adhesives, flexible coverings, packaging, etc., can solve the problems of printing and dyeing information carriers, affecting the distribution of adhesives, and affecting viewing, etc. Achieve the effect of not easy to wrinkle, ensure smoothness and increase toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

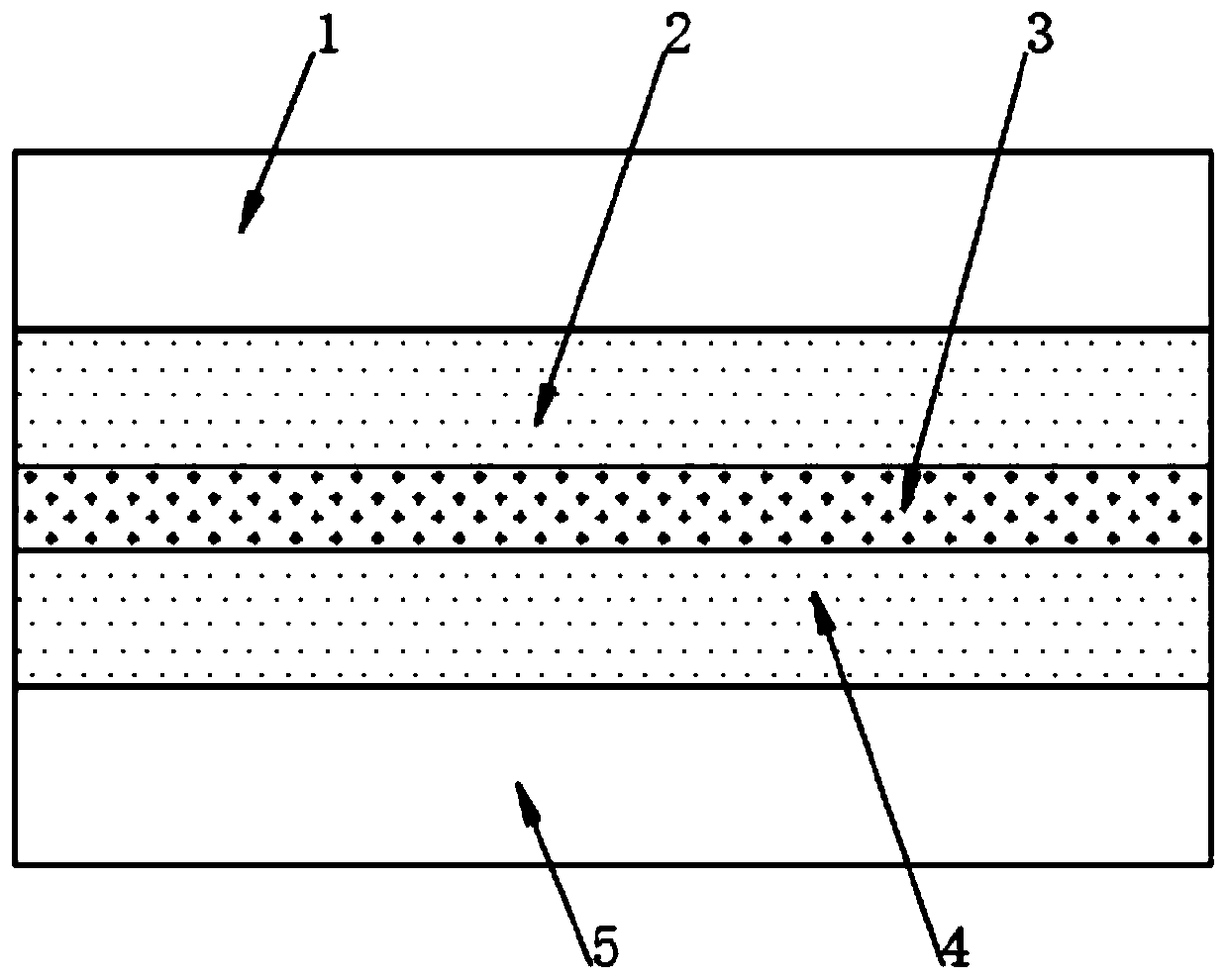

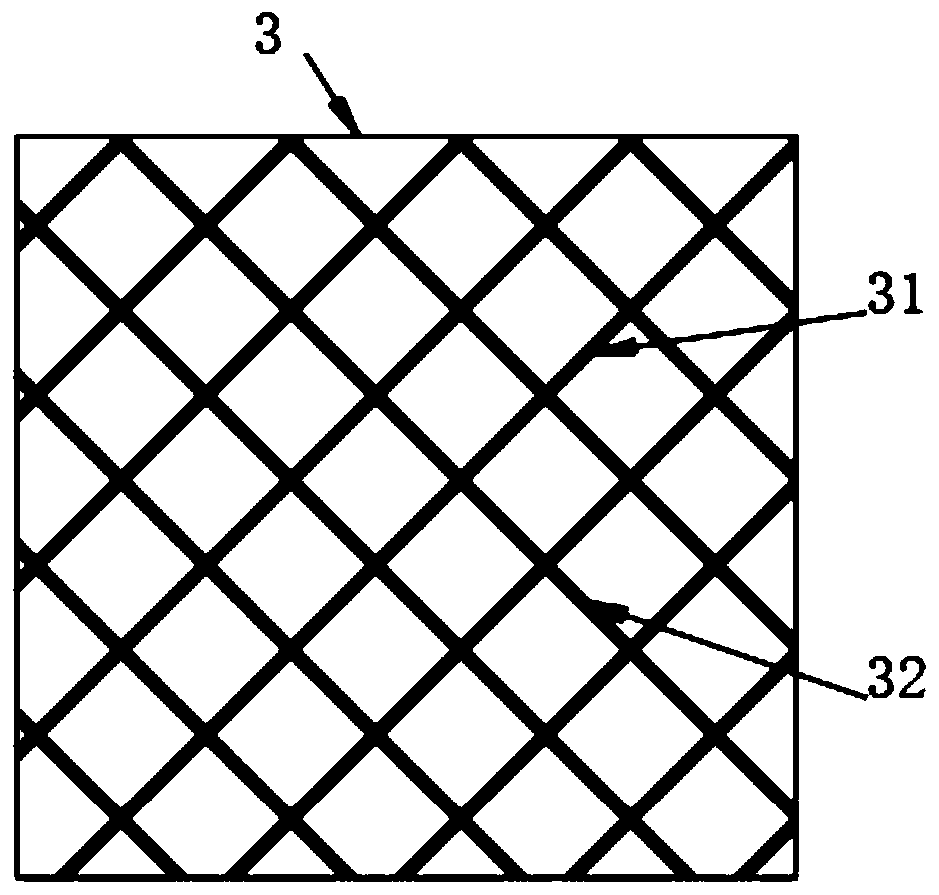

[0023] see figure 1 with Figure 4 , the present invention provides the following technical solutions: a CPP protective film with good flatness, comprising a first protective layer 1, a first adaptation layer 2, a support layer 3, a second adaptation layer 4 and a second protection layer 5, the support layer 3 The first adaptive layer 2 and the second adaptive layer 4 are respectively connected on both sides of the first adaptive layer 2, the other side of the first adaptive layer 2 is connected with the first protective layer 1, and the other side of the second adaptive layer 4 is bonded with the second protective layer. Layer 5, the supporting layer 3 includes several elastic supporting bars 301, and the cross section of the supporting bars 301 is prismatic.

[0024] Specifically, the support layer 3 is made of ethylene-propylene copolymer, and elastic particles 201 are arranged inside the first adaptation layer 2 and the second adaptation layer 4, and the diameter of the e...

Embodiment 2

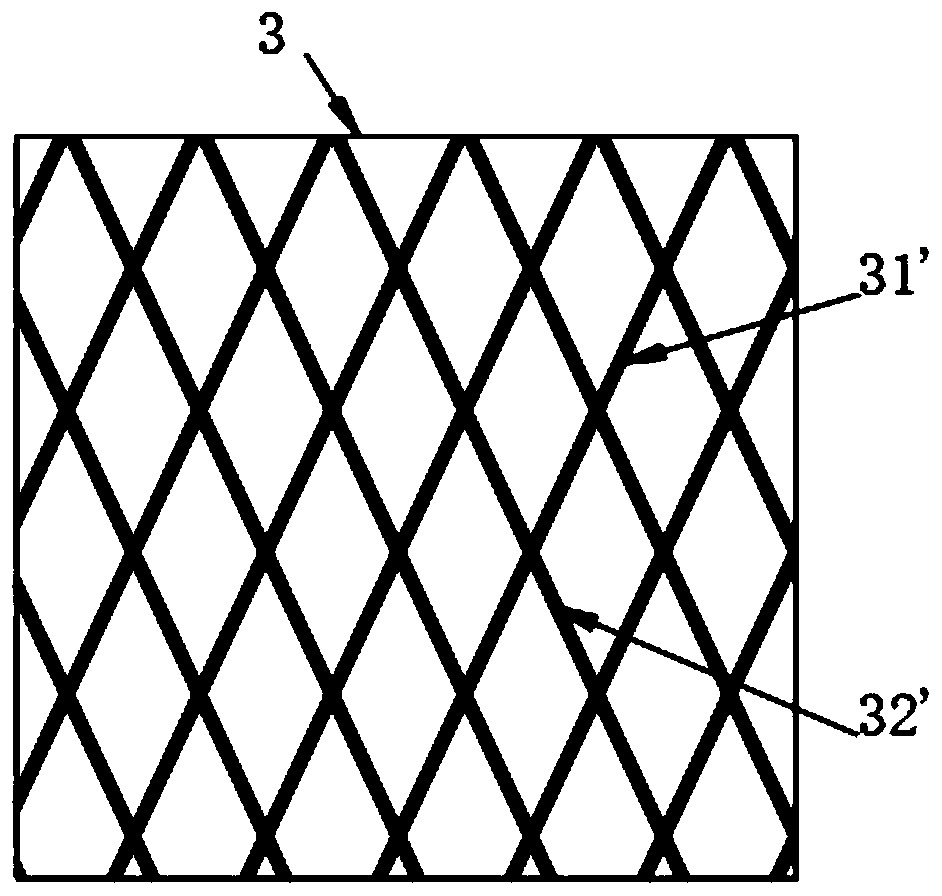

[0027] see figure 1 , 2 with Figure 4 , the present invention provides the following technical solutions: a CPP protective film with good flatness, comprising a first protective layer 1, a first adaptation layer 2, a support layer 3, a second adaptation layer 4 and a second protection layer 5, the support layer 3 The first adaptive layer 2 and the second adaptive layer 4 are respectively connected on both sides of the first adaptive layer 2, the other side of the first adaptive layer 2 is connected with the first protective layer 1, and the other side of the second adaptive layer 4 is bonded with the second protective layer. The layer 5, the supporting layer 3 includes several elastic supporting bars 301, and the cross section of the supporting bars 301 is spindle-shaped.

[0028] Specifically, the support layer 3 is made of ethylene-propylene copolymer, and elastic particles 201 are arranged inside the first adaptation layer 2 and the second adaptation layer 4, and the dia...

Embodiment 3

[0032] see figure 1 , 3 with Figure 4 , the present invention provides the following technical solutions: a CPP protective film with good flatness, comprising a first protective layer 1, a first adaptation layer 2, a support layer 3, a second adaptation layer 4 and a second protection layer 5, the support layer 3 The first adaptive layer 2 and the second adaptive layer 4 are respectively connected on both sides of the first adaptive layer 2, the other side of the first adaptive layer 2 is connected with the first protective layer 1, and the other side of the second adaptive layer 4 is bonded with the second protective layer. Layer 5, the support layer 3 includes several elastic support bars 301, the cross section of the support bars 301 is spindle-shaped or prismatic.

[0033] Specifically, the support layer 3 is made of ethylene-propylene copolymer, and elastic particles 201 are arranged inside the first adaptation layer 2 and the second adaptation layer 4, and the diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com