Self-circulating water treatment device for electrophoretic coating

A water treatment device, electrophoretic coating technology, applied in waste paint treatment, water/sewage treatment, water/sewage treatment equipment, etc., to achieve the effect of improving water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

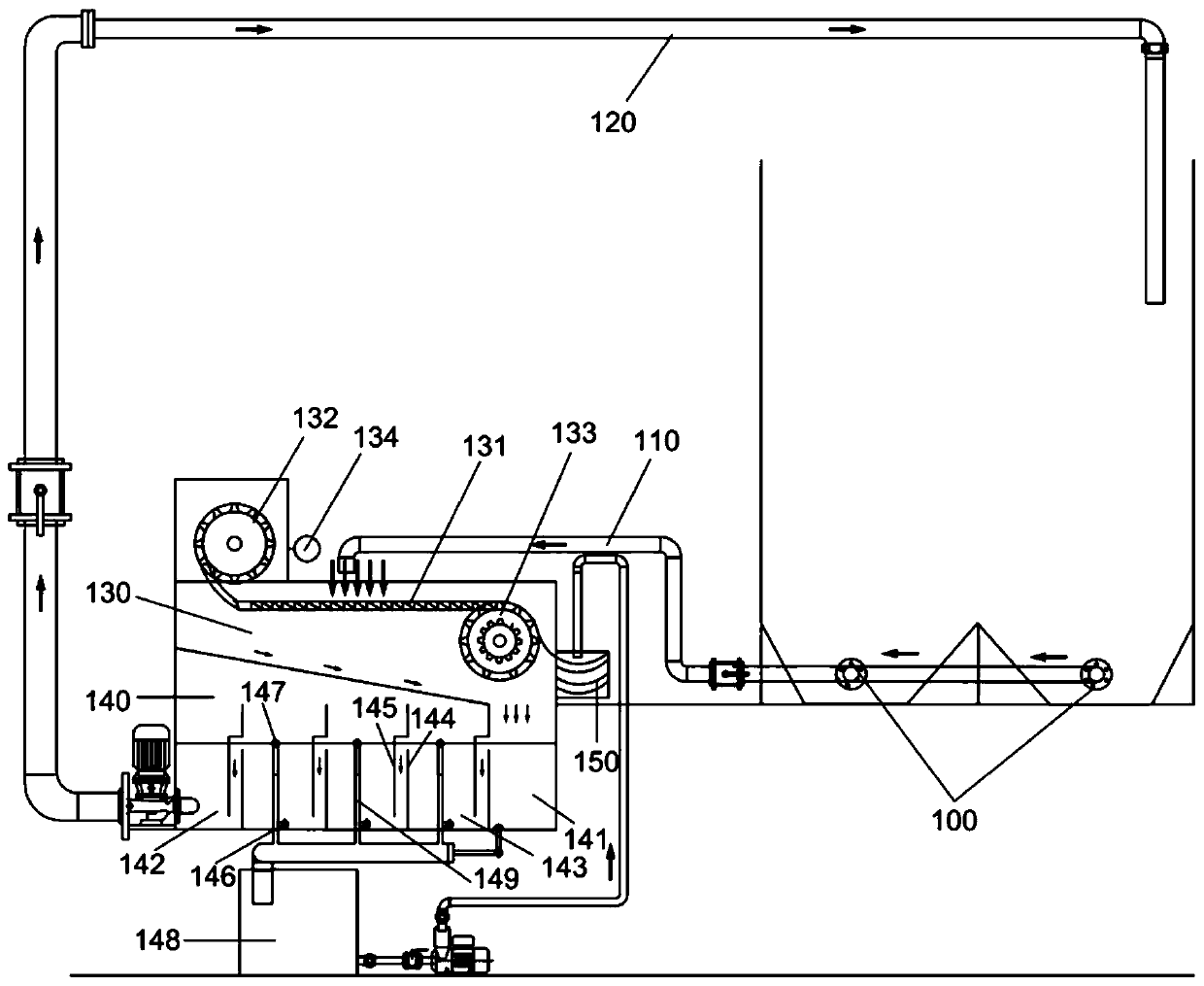

[0036]This embodiment provides a self-circulating water treatment device for electrophoretic coating. The self-circulating water treatment device for electrophoretic coating is connected to the sewage outlet 100 at the bottom of the spray degreasing area and / or hot scalding area through a water inlet pipe 110, Filter the electrophoretic coating wastewater discharged from the sewage outlet 100, and reuse it after filtering out the grease and solid particles in the electrophoretic coating wastewater through the self-circulating water treatment device for electrophoretic coating in this embodiment.

[0037] Such as figure 1 As shown, a self-circulating water treatment device for electrophoretic coating includes: a filter tank 130, a filter cloth 131 and a reel group are arranged in the filter tank 130; Below the outlet of the water pipe 110; the reel set includes a first reel 132 and a second reel 133 arranged in parallel, the first reel 132 is used to take up the filter cloth 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com