Preparation method of polymer-based composite energetic material-coated modified nano metal particles

A technology of nano metal particles and polymers, used in offensive equipment, explosives processing equipment, non-explosive/non-thermal agent components, etc., can solve problems such as poor practicability, and achieve easy oxidation, excellent mechanical properties, and good practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

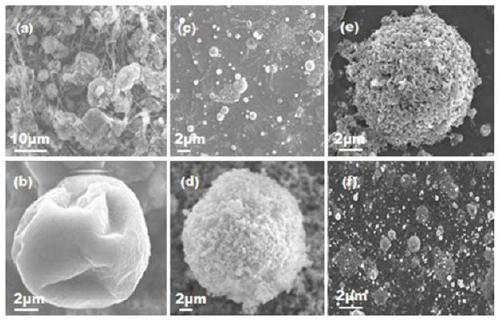

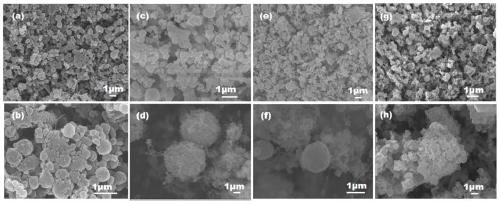

[0030] The preparation method of polymer NC coated nano metal silicon powder particles comprises the following process steps:

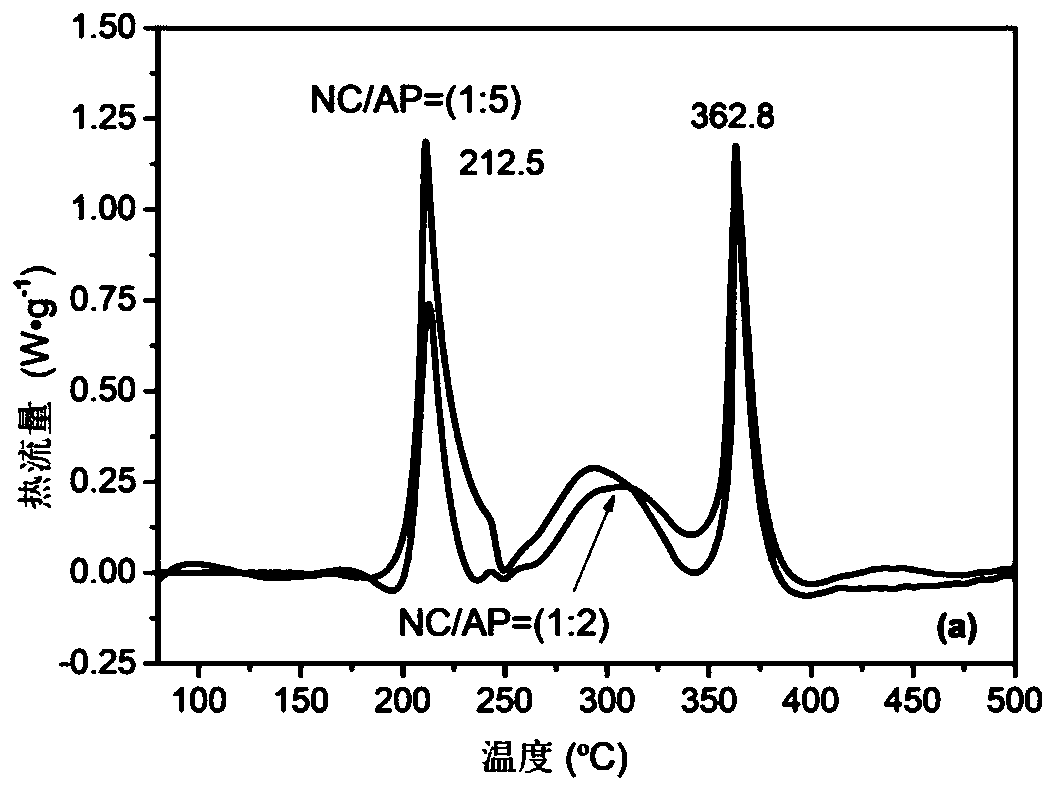

[0031] Coating of nano-silica powder: 100mg NC was dried in an oven at 60°C for 1 hour to remove moisture. Afterwards, NC was dissolved in a mixed solvent of 12 ml acetone (AR) and 3 ml N,N-dimethylformamide (DMF) (volume ratio 4:1), and sonicated for 1 hour. 200 mg of nano-Si powder was added to the NC solution at a certain ratio (the mass ratio of NC and Si was 1:2), and magnetically stirred for 2 hours to obtain a NC / Si suspension.

[0032] Doping of the energetic oxidant AP: 200 mg of AP was ground in a mortar with acetone solvent for half an hour. At the same time, gently pour the ground AP into the NC / Si suspension in a certain ratio (the mass ratio of NC and AP is 1:2), and stir it magnetically for 2 hours to obtain the final precursor solution of NC / AP / Si .

[0033] Preparation of composite nanoparticles by electrostatic spraying method: put ...

Embodiment 2

[0038] Coating of nano silicon powder: 66.66mg NC was dried in an oven at 60°C for 1 hour to remove moisture. Afterwards, NC was dissolved in a mixed solvent of 8ml acetone (AR) and 2ml N,N-dimethylformamide (DMF) (AR:DMF=4:1), and sonicated for 1 hour. 300mg of nano-Si powder was added to the NC solution at a certain ratio (the mass ratio of NC and Si was 1:4.5), and magnetically stirred for 2 hours to obtain a NC / Si suspension.

[0039] Doping of the energetic oxidant AP: 133.34 mg AP was ground in a mortar with acetone solvent for half an hour. At the same time, gently pour the ground AP into the NC / Si suspension in a certain ratio (the mass ratio of NC and AP is 1:2), and stir it magnetically for 2 hours to obtain the final precursor solution of NC / AP / Si .

[0040] Preparation of composite nanoparticles by electrostatic spraying method: put the prepared NC / AP / Si precursor solution into a syringe (the inner diameter of the needle is 6.25mm), and the injection speed is 1.5...

Embodiment 3

[0045] Coating of nano silicon powder: 33.3mg NC was dried in an oven at 60°C for 1 hour to remove moisture. NC was dissolved in a mixed solvent of 4 ml acetone (AR) and 1 ml N,N-dimethylformamide (DMF) (volume ratio 4:1), and sonicated for 1 hour. 400 mg of nano-Si powder was added to the NC solution at a certain ratio (the mass ratio of NC and Si was 1:12), and magnetically stirred for 2 hours to obtain a NC / Si suspension.

[0046] Doping of the energetic oxidant AP: 66.7 mg AP was ground in a mortar with acetone solvent for half an hour. At the same time, gently pour the ground AP into the NC / Si suspension in a certain ratio (the mass ratio of NC and AP is 1:2), and stir it magnetically for 2 hours to obtain the final precursor solution of NC / AP / Si .

[0047] Preparation of composite nanoparticles by electrostatic spraying method: put the prepared NC / AP / Si precursor solution into a syringe (the inner diameter of the needle is 6.25mm), and the injection speed is 0.6mm min ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com