A kind of anisotropic conductive adhesive and its preparation method and application

An anisotropic, conductive adhesive technology, applied in the field of conductive adhesives, can solve the problems of electrical conductivity and bonding performance to be improved, and achieve the effects of low raw material cost, stable electrical conductivity, and small on-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

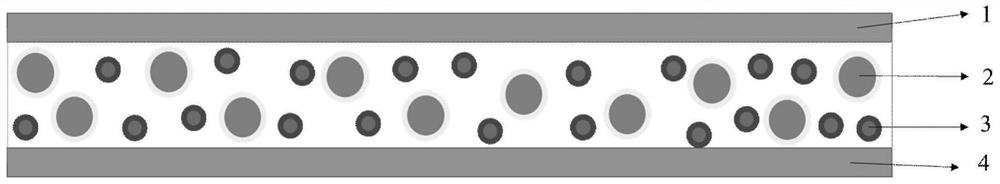

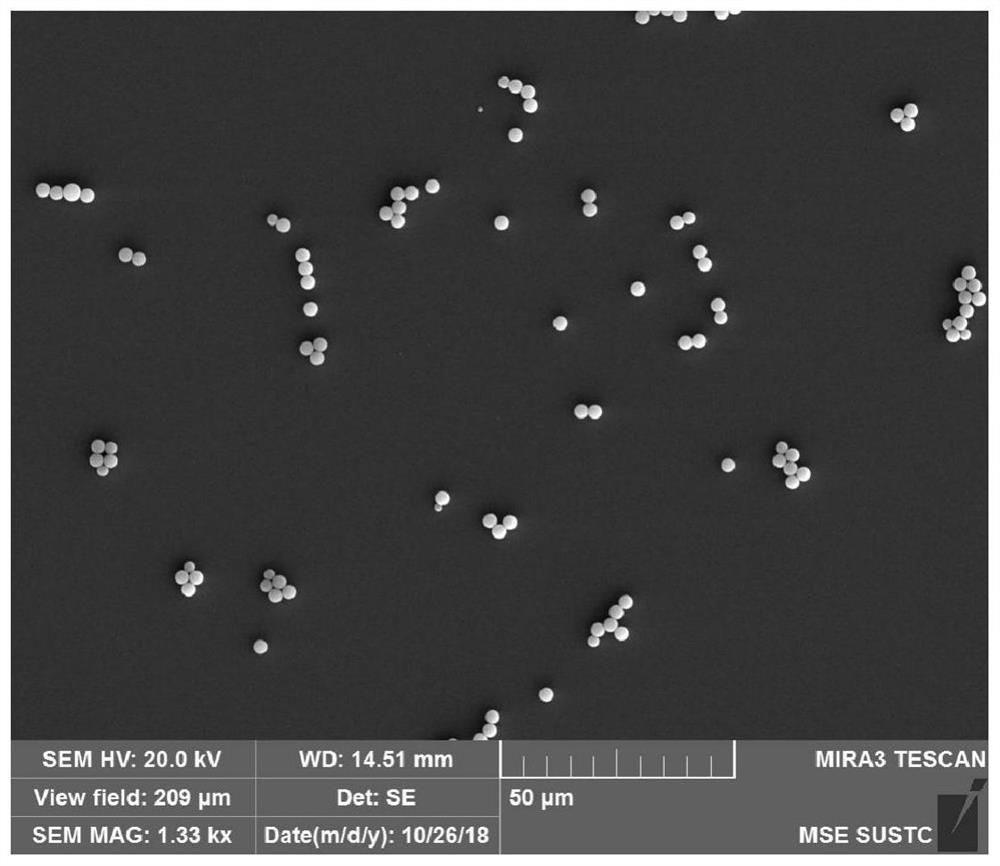

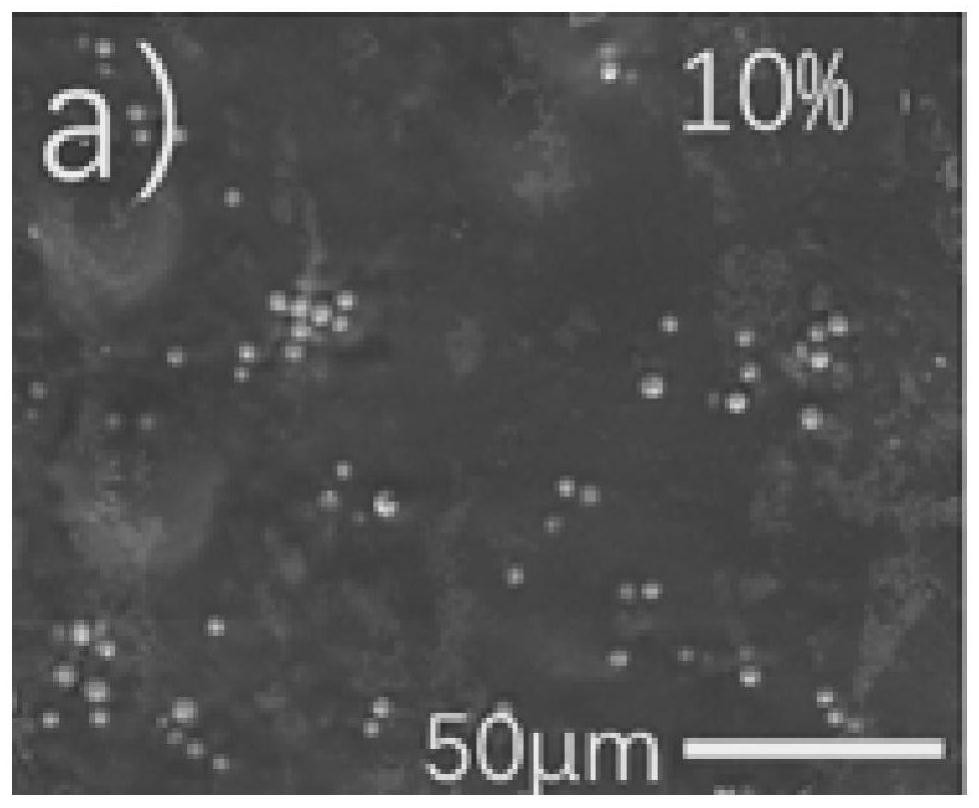

[0057] A kind of preparation method of anisotropic conductive adhesive of the present embodiment comprises the following steps:

[0058] 1) Prepare the main glue; take the conductive filler with spherical polystyrene as the core and mix the epoxy resin compound at a mass ratio of 2:10, add TPU, wherein the conductive filler with spherical polystyrene as the core has a microscopic size of 5 μm The ball, the epoxy resin compound is composed of liquid epoxy resin E51 and solid epoxy resin E44, the mass ratio of liquid epoxy resin E51 to solid epoxy resin E44 is 1:1, the mass ratio of TPU to epoxy resin compound 0.3:1, stir for 30 minutes to mix evenly to obtain the main glue;

[0059] 2) preparing curing agent microcapsules;

[0060] 1') Polystyrene is dissolved in methylene chloride to obtain a solution, wherein the mass ratio of polystyrene to methylene chloride is 1:25;

[0061] 2') Add the solution obtained in step 1') to an equal volume of dispersion solution, wherein the ...

Embodiment 2

[0065] A kind of preparation method of anisotropic conductive adhesive of the present embodiment comprises the following steps:

[0066] 1) Prepare the main glue; take the conductive filler with spherical polystyrene as the core and mix the epoxy resin compound at a mass ratio of 2:10, add TPU, wherein the conductive filler with spherical polystyrene as the core has a microscopic size of 5 μm The ball, the epoxy resin compound is composed of liquid epoxy resin E51 and solid epoxy resin E44, the mass ratio of liquid epoxy resin E51 to solid epoxy resin E44 is 1:1, the mass ratio of TPU to epoxy resin compound 0.3:1, stir for 30 minutes to mix evenly to obtain the main glue;

[0067] 2) preparing curing agent microcapsules;

[0068] 1') Polystyrene is dissolved in methylene chloride to obtain a solution, wherein the mass ratio of polystyrene to methylene chloride is 1:25;

[0069] 2') Add the solution obtained in step 1') to an equal volume of dispersion solution, wherein the ...

Embodiment 3

[0072] A kind of preparation method of anisotropic conductive adhesive of the present embodiment comprises the following steps:

[0073] 1) Prepare the main glue; take the conductive filler with spherical polystyrene as the core and mix the epoxy resin compound at a mass ratio of 15:100, and add TPU, wherein the size of the conductive filler with spherical polystyrene as the core is 5 μm. The ball, the epoxy resin compound is composed of liquid epoxy resin E51 and solid epoxy resin E44, the mass ratio of liquid epoxy resin E51 to solid epoxy resin E44 is 1:1, the mass ratio of TPU to epoxy resin compound 0.3:1, stir for 30 minutes to mix evenly to obtain the main glue;

[0074] 2) preparing curing agent microcapsules;

[0075] 1') Polystyrene is dissolved in methylene chloride to obtain a solution, wherein the mass ratio of polystyrene to methylene chloride is 1:25;

[0076] 2') Add the solution obtained in step 1') to an equal volume of dispersion solution, wherein the disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com