Furnace temperature measuring blank and furnace temperature uniformity measuring method

A measurement method and uniformity technology, which is applied in the field of temperature uniformity measurement of induction heating furnace before material processing, which can solve the problem of low temperature, inability to accurately reflect the temperature uniformity of the heated ingot metal at the same time, and inability to reflect the heating of the ingot in real time and other problems, to achieve the effect of accurate temperature and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

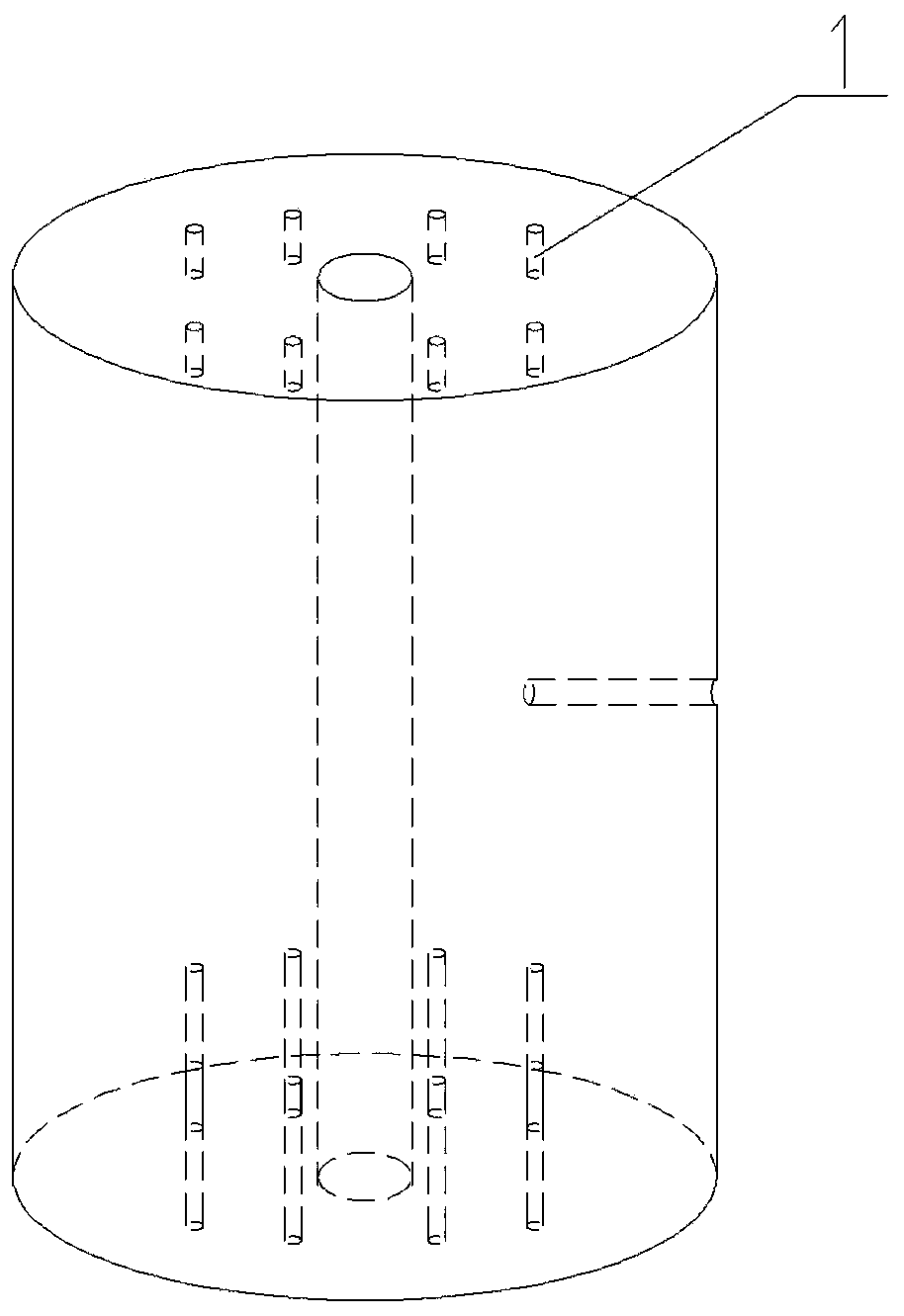

[0052] figure 1 A schematic diagram of the structure of a billet for measuring furnace temperature uniformity with an outer diameter of 230mm provided by an embodiment.

[0053] Please refer to figure 1 , The measurement blank size specification is 400mm in length, 230mm in outer diameter and 30mm in inner diameter. according to figure 1 The layout of the temperature measuring hole 1, using a Φ4mm drill bit to drill 17 thermocouple temperature measuring holes 1.

[0054]Optionally, the measuring blank is a hollow ingot, but not limited thereto.

[0055] Insert 17 Φ3mm armored K-type thermocouples into the temperature measuring hole 1 of the billet in sequence, insert them into the bottom of the hole and fix them, and connect the other end to the motor data temperature recorder.

[0056] There are 8 thermocouples arranged on the upper end surface of the billet. The depth of the temperature measuring hole 1 on the upper end face is 50mm. There are 8 thermocouples arranged o...

Embodiment 2

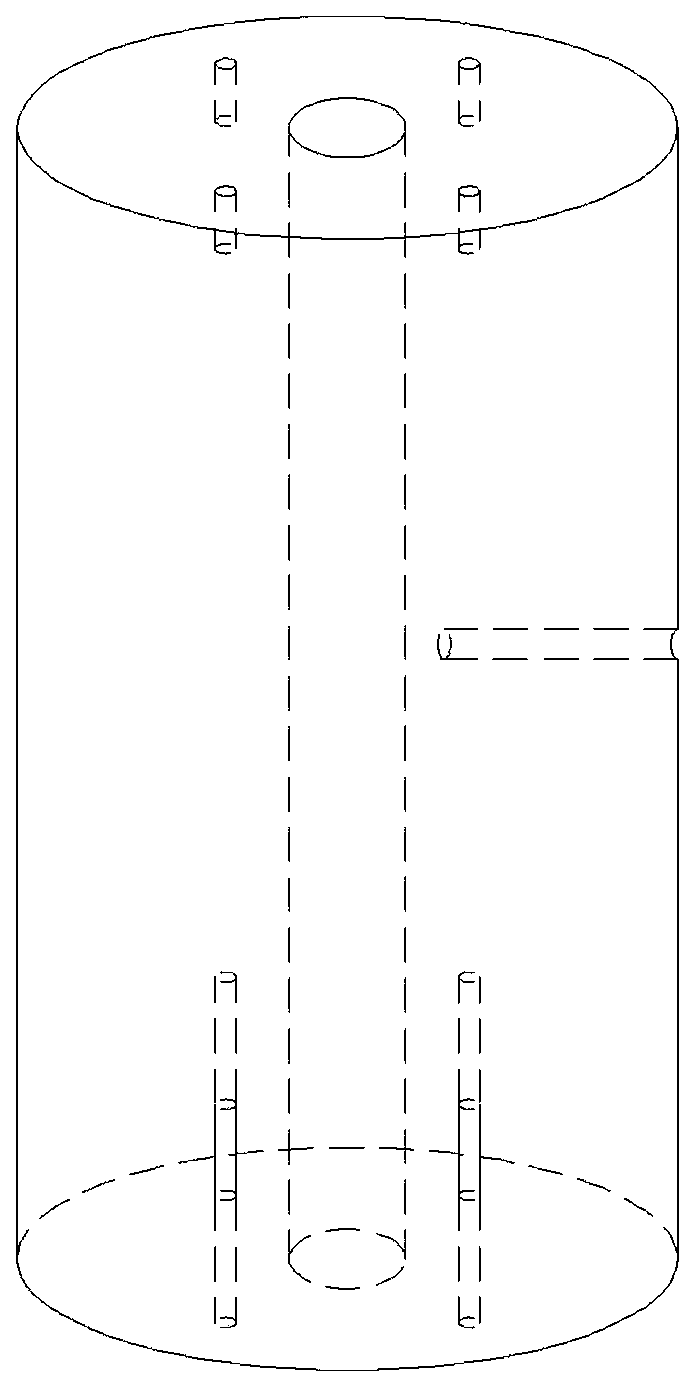

[0070] figure 2 A schematic diagram of the structure of a billet for measuring furnace temperature uniformity with an outer diameter of 180mm provided by an embodiment.

[0071] Please refer to figure 2 , The measurement blank size specification is 600mm in length, 180mm in outer diameter and 50mm in inner diameter. according to figure 2 Layout diagram of temperature measuring hole 1, using a Φ4mm drill bit to drill 9 thermocouple temperature measuring holes 1.

[0072] Insert 9 Φ3mm armored K-type thermocouples into the temperature measuring hole 1 of the billet in sequence, insert them into the bottom of the hole and fix them, and connect the other end to the motor data temperature recorder.

[0073] There are 4 thermocouples arranged on the upper surface of the billet. The depth of the temperature measuring hole 1 on the upper surface is 75mm. There are 4 thermocouples arranged on the lower end surface of the billet. The depth of the temperature measuring hole 1 on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com