A low-temperature sintered back silver paste for all-aluminum back field crystalline silicon solar cells

A technology for solar cells and low-temperature sintering, which is applied in circuits, photovoltaic power generation, electrical components, etc., and can solve the problems of reducing the opening voltage of PERC solar cells, reducing the photoelectric conversion efficiency of PERC solar cells, and the adhesion of low-temperature curing backside silver paste printing backside electrodes To achieve the effect of improving field passivation characteristics, improving photoelectric conversion efficiency, and reducing leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation of low temperature sintered back silver paste

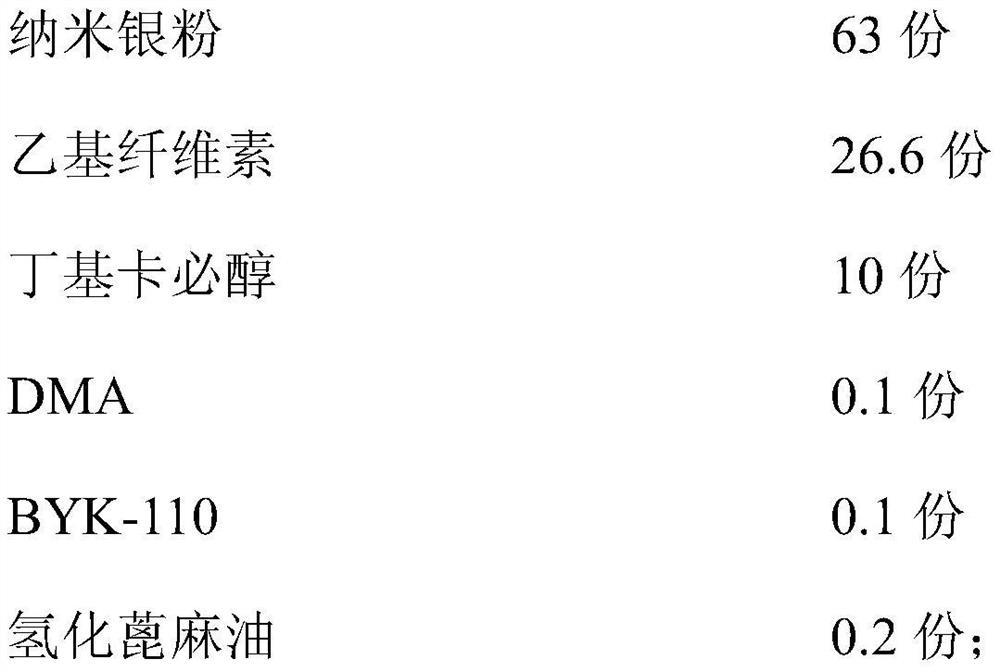

[0034]The invention provides a low-temperature sintered back silver paste for an all-aluminum back field crystalline silicon solar cell that reduces the recombination of carriers and the formation of silver-aluminum alloys. The process of using the silver paste is simple and suitable for existing The technological process, the technical point is: the low-temperature sintering type back silver paste is prepared by including the following components in parts by mass:

[0035]

[0036] Wherein, the tap density of the nano-silver powder is 3.25g / cm 3 , the specific surface area of the nano-silver powder is 5cm 2 / g, the median diameter D of the nano-silver powder 50 is 0.275 μm, the particle size span of the nano-silver powder is 0.85, and the burning loss rate of the nano-silver powder is 0.15%. Mix the above-mentioned nano-silver powder, ethyl cellulose, butyl carbitol, DMA, BYK-110 and hydrogenated ca...

Embodiment 2

[0046] 1. Preparation of Glass Powder

[0047] Prepare 65 parts of Pb 2 o 3 , 10 copies of B 2 o 3 , 5 parts of ZnO, 1 part of SiO 2 , 1 part of Al 2 o 3 , 1 part of NiO and 2 parts of V 2 o 5 , and then use a known mixer such as a disperser or a three-roller to mix the materials evenly, and then perform a drying treatment for 3.5 hours, then transfer the dried raw materials to the crucible, and then place the crucible containing the raw materials into the heating chamber In the chamber, first raise the temperature to 950°C, then keep it warm for 1.5 hours, then pass the smelted material liquid through cooling rollers to obtain glass frit, then crush and sieve the glass frit to obtain the median particle size D 50 Glass frit with a thickness of 0.3 μm and a softening point of 350°C.

[0048] 2. Preparation of low temperature sintered back silver paste

[0049] The invention provides a low-temperature sintered back silver paste for an all-aluminum back field crystalli...

Embodiment 3

[0061] 1. Preparation of Glass Powder

[0062] Prepare 60 servings of Bi 2 o 3 , 20 copies of B 2 o 3 , 10 parts of Zn 3 (PO 4 ) 2 , 10 parts of SiO 2 , 3 parts of Al 2 o 3 , 3 parts of NiO and 5 parts of V 2 o 5 , and then use a known mixer such as a disperser or a three-roller to mix the materials evenly, and then perform a drying treatment for 3.5 hours, then transfer the dried raw materials to the crucible, and then place the crucible containing the raw materials into the heating chamber In the chamber, first raise the temperature to 1050°C, then keep it warm for 1 hour, then pass the smelted material liquid through cooling rollers to obtain glass frit, then crush and sieve the glass frit to obtain the median particle size D 50 Glass frit with a thickness of 0.4 μm and a softening point of 250°C.

[0063] 2. Preparation of low temperature sintered back silver paste

[0064] The invention provides a low-temperature sintered back silver paste for an all-aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com