Pluggable structure for L-type connectors of high-voltage cables of electric multiple units

A high-voltage cable and connector technology, applied in vehicle connectors, parts and connections of connecting devices, etc., can solve problems such as restricting the development of railway transportation, inconvenient product installation and post-maintenance, and products that cannot fully meet the pluggable function, etc. problem, to achieve the effect of convenient installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

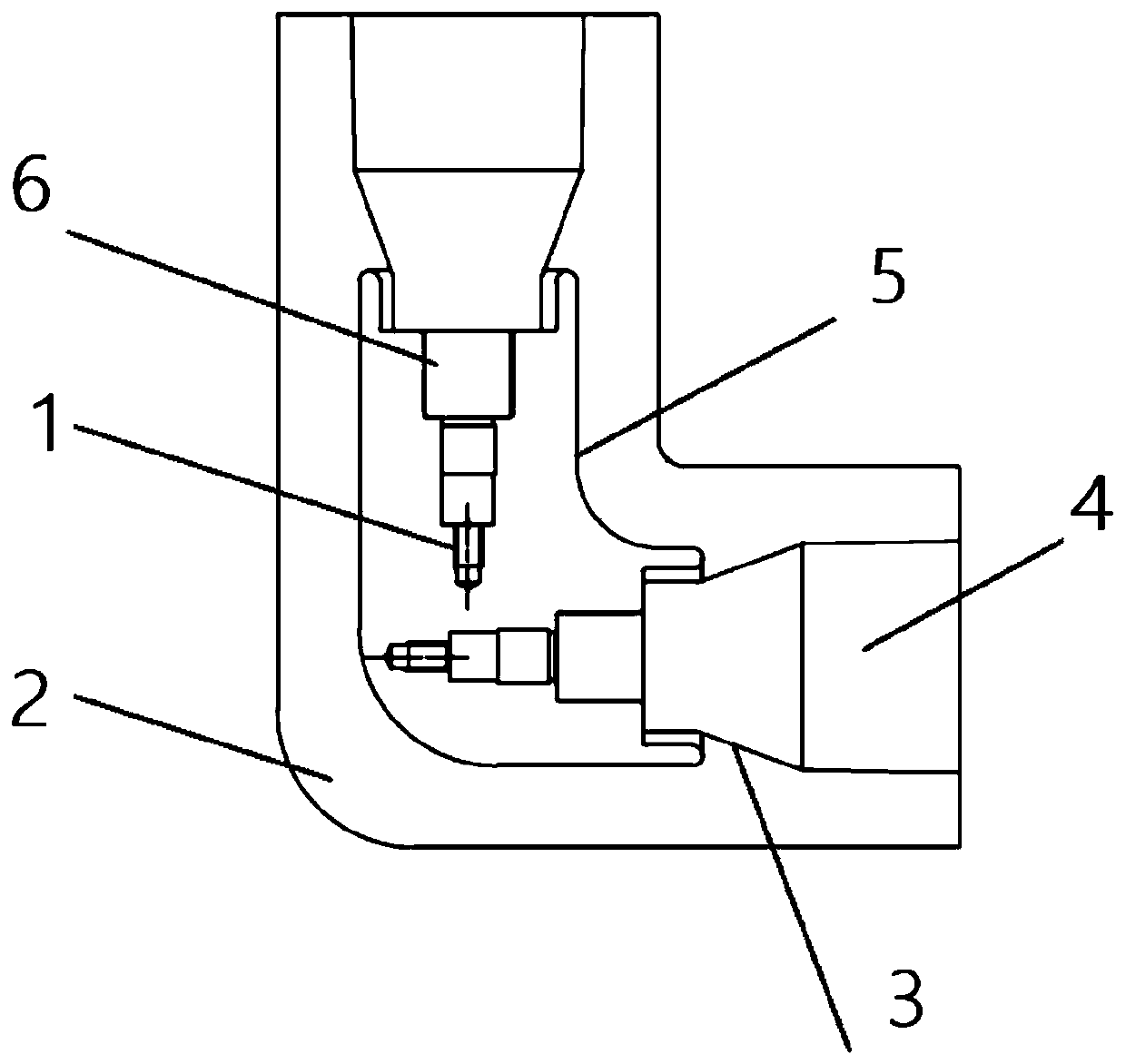

[0021] Such as figure 1 shown.

[0022] A pluggable structure for an L-shaped connector of a high-voltage cable of an EMU, comprising a pair of joint units arranged in an L shape; the pair of joint units are connected by an L-shaped connector, and the L-shaped connector includes a socket set The L-shaped central conductor 5 and the L-shaped insulating sleeve 2; the joint unit includes the contact head 1 and the stress cone 4 arranged in sequence; the two ends of the L-shaped central conductor 5 are provided with the contact head 1 and the stress cone 4 matching grooves;

[0023] The groove at the end of the L-shaped central conductor 5 is provided with a watch strap contact finger reed socket structure; one end of the contact head 1 is pluggably connected to the watch strap contact finger reed socket structure, and the other One end is connected to the cable 6; the stress cone 4 is a conical structure, and the top of the stress cone 4 is provided with an upper slope that mat...

Embodiment 2

[0026] As described in Embodiment 1, the pluggable structure for the L-shaped connector of the high-voltage cable of the EMU, further, the pluggable structure for the L-shaped connector of the high-voltage cable of the EMU also includes a protection unit, the The protection unit includes an L-shaped protective shell and an L-shaped cover plate matched with the L-shaped protective shell; both ends of the protective unit are open, and the joint unit is embedded in the opening at the end of the protective unit.

[0027] The material of the L-shaped central conductor 5 is aluminum alloy, and the surface layer is silver-plated; the material of the L-shaped insulating sleeve is epoxy resin; the material of the stress cone is EPDM rubber; the contact head is aluminum alloy, and the surface layer Silver plating treatment; Inorganic flame retardants and organic flame retardants are added to the components of the L-shaped insulating sleeve and the stress cone; the material of the protect...

Embodiment 3

[0029] As for the pluggable structure for the L-shaped connector of the high-voltage cable of the EMU described in Embodiment 1, further, the L-shaped insulating sleeve 2 is composed of a long tube and a short tube. One is short and the other is long for the insulation sleeve 2, which is convenient for distinguishing the installation units.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com