Low loss galvanic isolation circuitry

A technology for galvanic isolation and isolation of circuits, applied in circuits, transmission systems, baseband systems, etc., and can solve problems such as increasing data delay, data rate limitation, and signal path attenuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the drawings, like reference numerals identify like elements throughout, and the various features are not necessarily drawn to scale. In this specification, the term "couple / coupled / couples" includes indirect or direct electrical or mechanical connections or combinations thereof. For example, if a first device is coupled to or with a second device, that connection may be through a direct electrical connection, or through an indirect electrical connection via one or more intervening devices and connections.

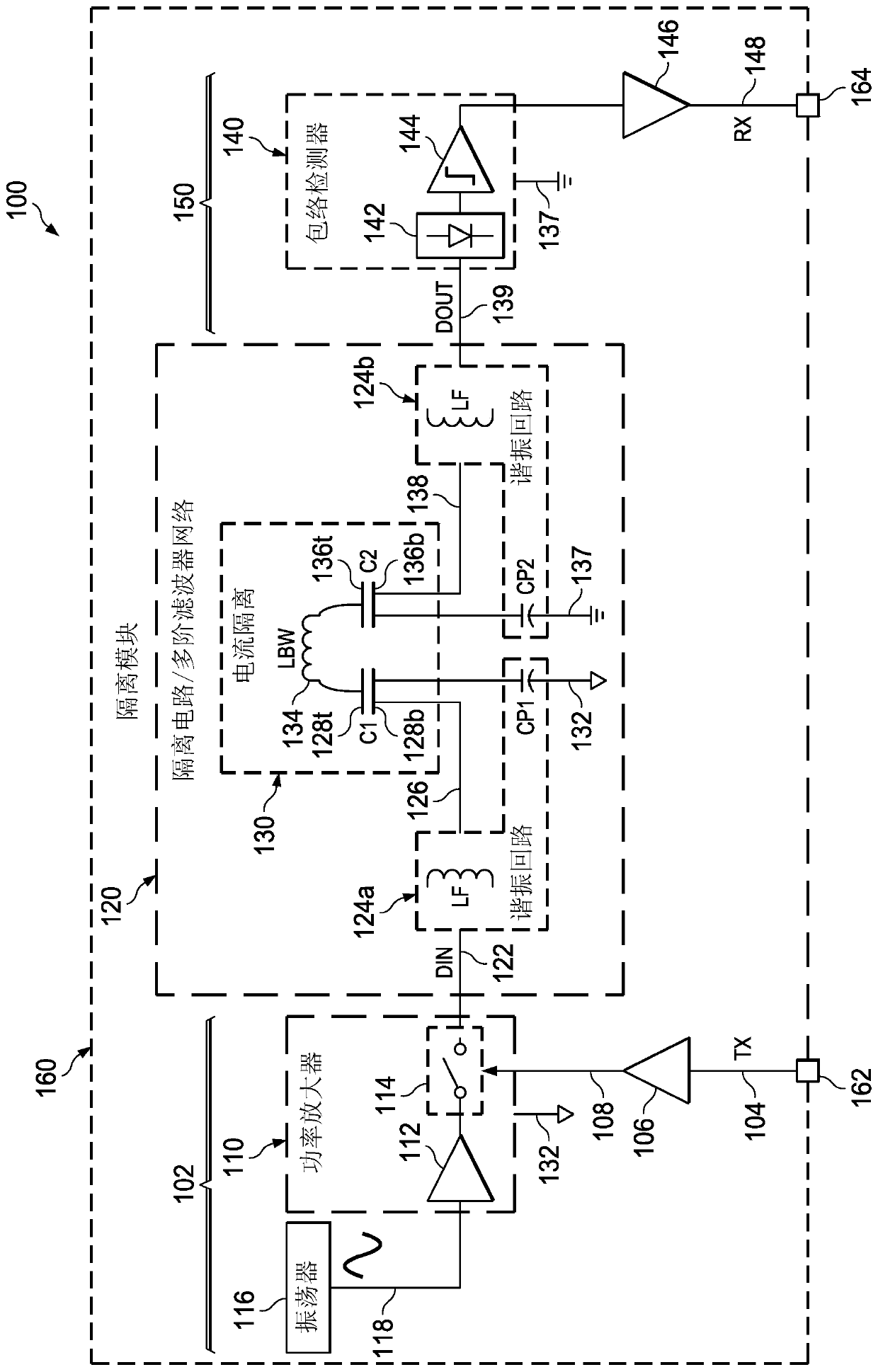

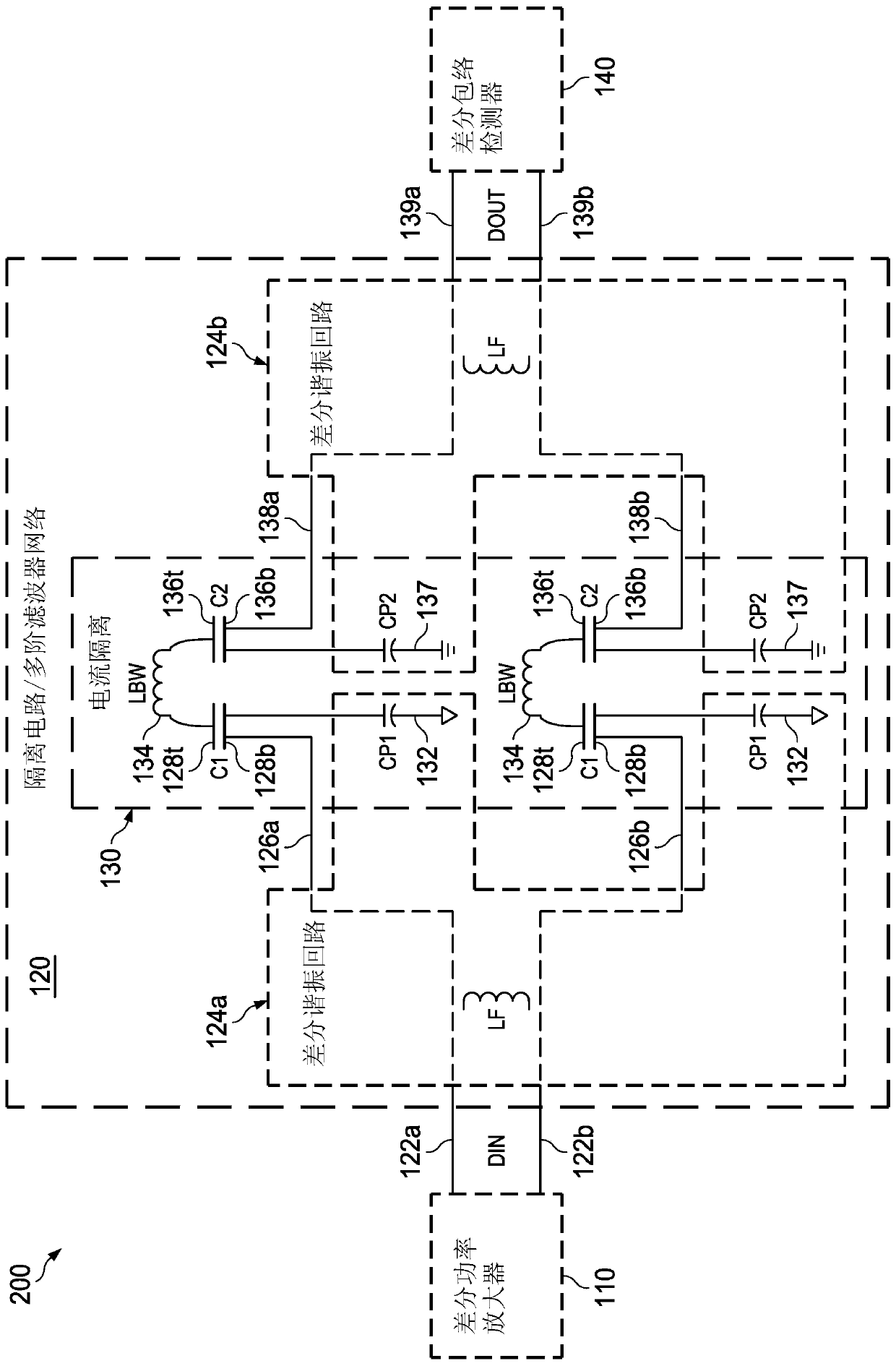

[0021] refer to figure 1 , the described example provides capacitive coupling isolation circuitry 120, system and filter circuitry. Examples include a capacitively coupled isolation circuit 130 having a first coupling capacitor C1 and a second coupling capacitor C2 connected by a bond wire 134, and a first circuit 124a and a second circuit 124b having an inductor LF to create a circuit with coupling Capacitors C1 and C2 are associated with parasitic capacitors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com