Preparation method of emulsion type polyether-modified silicon antifoaming agent

A technology of polyether-modified silicon and defoamer, which is applied in separation methods, chemical instruments and methods, and liquid degassing, etc., can solve the problems of low compatibility, cannot effectively and quickly reduce the surface shrinkage of water-based coatings, etc. Increase compatibility, reduce the risk of shrinkage crater, and improve the effect of foam suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

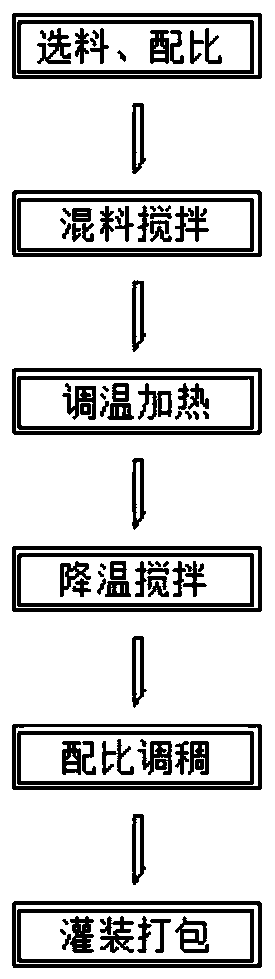

[0023] see figure 1 , the present invention provides a technical solution: a preparation method of an emulsion-type polyether-modified silicon defoamer, characterized in that: the steps of the preparation method of the emulsion-type polyether-modified silicon defoamer are divided into: each ingredient The proportion range of the whole emulsion type polyether modified silicon defoamer is: water 23%, dimethyl-3-hydroxypropyl methyl 30%, polypropylene glycol 9%, vegetable oil 8%, glyceryl monostearate 10% %, polyethylene glycol monooleate 10% and thickener 10%; the above ratio of dimethyl-3-hydroxypropylmethyl, polypropylene glycol, vegetable oil, glyceryl monostearate and polyethylene glycol Alcohol monooleate is put into a reaction kettle equipped with a stainless steel stirring blade, a motor and a heating system, and the above-mentioned ingredients are mixed evenly at room temperature; the above-mentioned uniformly stirred raw materials are heated to 120°C through the above-m...

Embodiment 2

[0030] see figure 1 , the present invention provides a technical solution: a preparation method of an emulsion-type polyether-modified silicon defoamer, characterized in that: the steps of the preparation method of the emulsion-type polyether-modified silicon defoamer are divided into: each ingredient The proportion range of the whole emulsion type polyether modified silicon defoamer is: water 30%, dimethyl-3-hydroxypropyl methyl 25%, polypropylene glycol 9%, vegetable oil 11%, glyceryl monostearate 10% %, polyethylene glycol monooleate 7% and thickener 8%; the above ratio of dimethyl-3-hydroxypropyl methyl, polypropylene glycol, vegetable oil, glyceryl monostearate and polyethylene glycol Alcohol monooleate is put into a reaction kettle equipped with a stainless steel stirring blade, a motor and a heating system, and the above-mentioned ingredients are mixed evenly at room temperature; the above-mentioned uniformly stirred raw materials are heated to 120°C through the above-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com