Motor vehicle wheel with device for updating wheels

A technology for motor vehicles and wheels, applied in the field of wheels of the device, can solve the problems of not being able to optimally form the contour to be printed, failure, incompatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

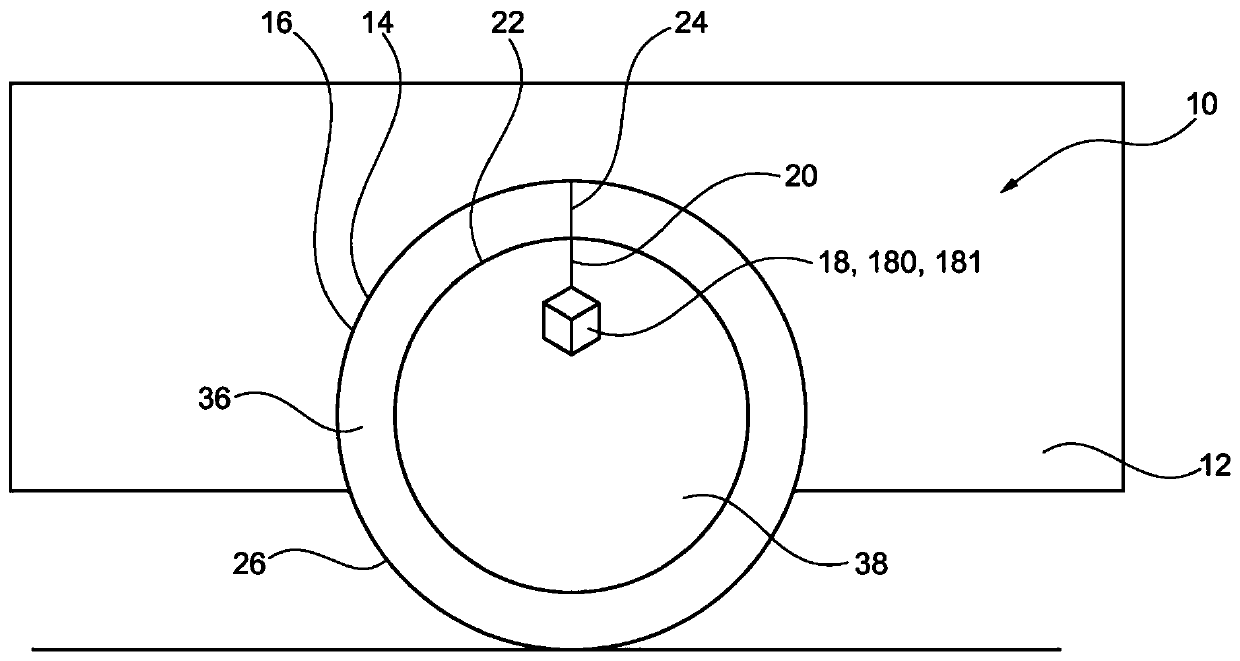

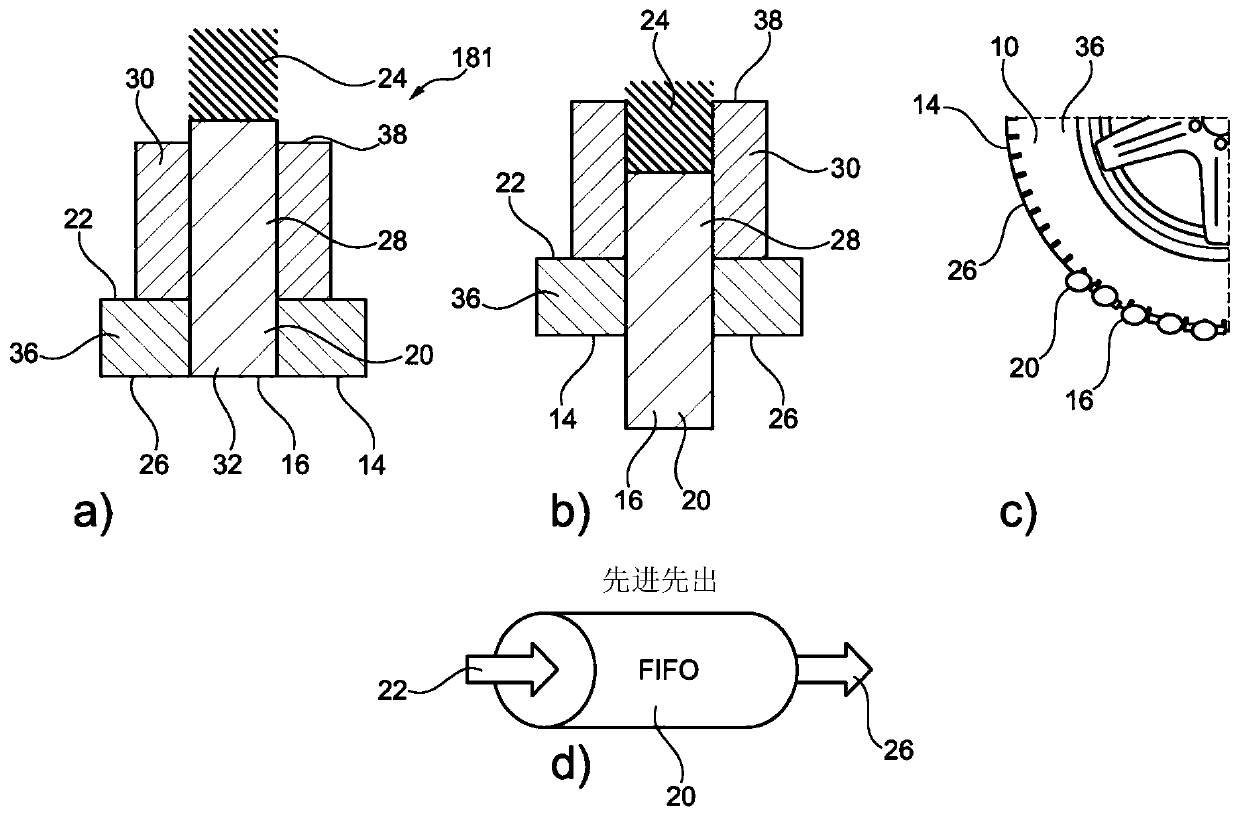

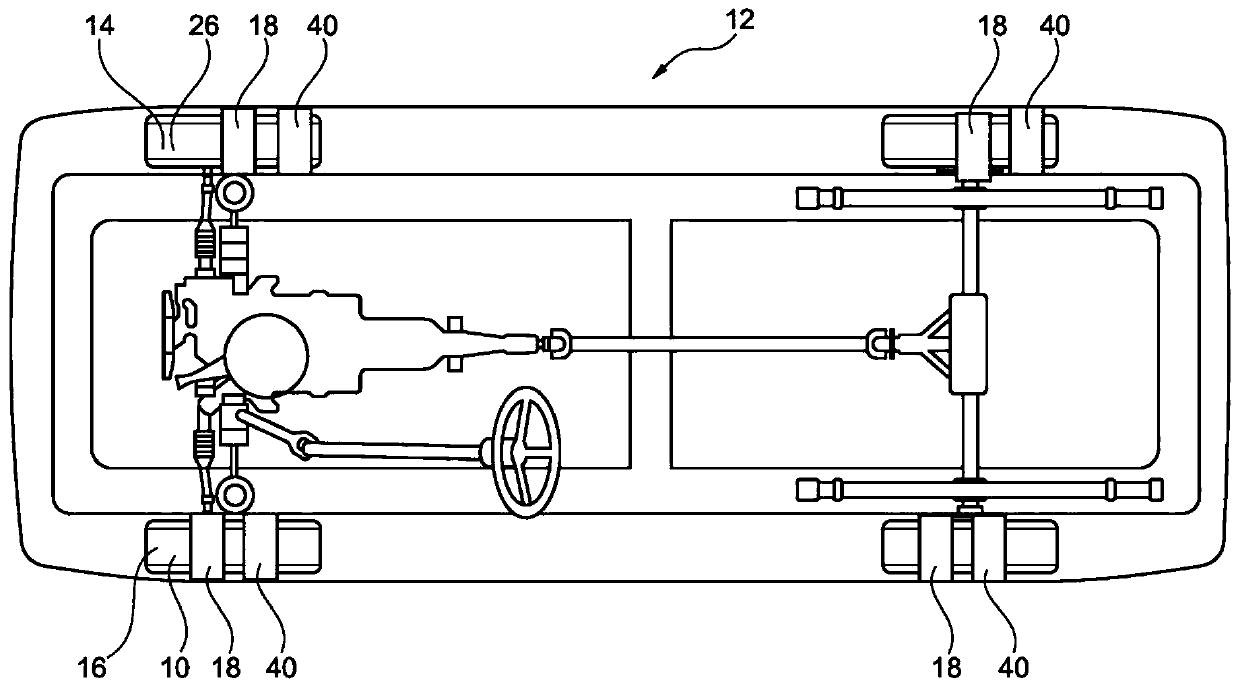

[0032] In the different figures, the same components are always given the same reference numerals, so that they will also generally only be described once.

[0033] exist figure 1 , a wheel 10 according to the invention is shown for a motor vehicle 12 . The wheel 10 includes a tread surface 14 on a tire 36 having a radially outwardly directed profile 16 . The wheel 10 of the motor vehicle 12 rolls on the terrain with the tread surface 14 in contact with the terrain with the contour 16 . Consequently, the profile 16 wears on the terrain surface and the depth of the profile 16 decreases.

[0034] In order to counteract the wear of the profile 16 , a device 18 is arranged within the wheel 10 which applies a material 20 to the inner side 22 of the tread surface 14 . The device 18 can be moved in the axial and / or circumferential direction of the cylindrical wheel 10 . A plurality of devices 18 may be arranged in the wheel 10 , wherein the devices 18 are preferably arranged adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com