Grounding structure for electroplating decoration ring

A grounding structure and decorative ring technology, applied in the direction of conductive connection, upper structure, upper structure sub-assembly, etc., can solve the problems of touch screen flickering, easy coupling of driving PCB board, and no effect of touch, etc., to achieve enhanced anti-corrosion The effect of damage strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

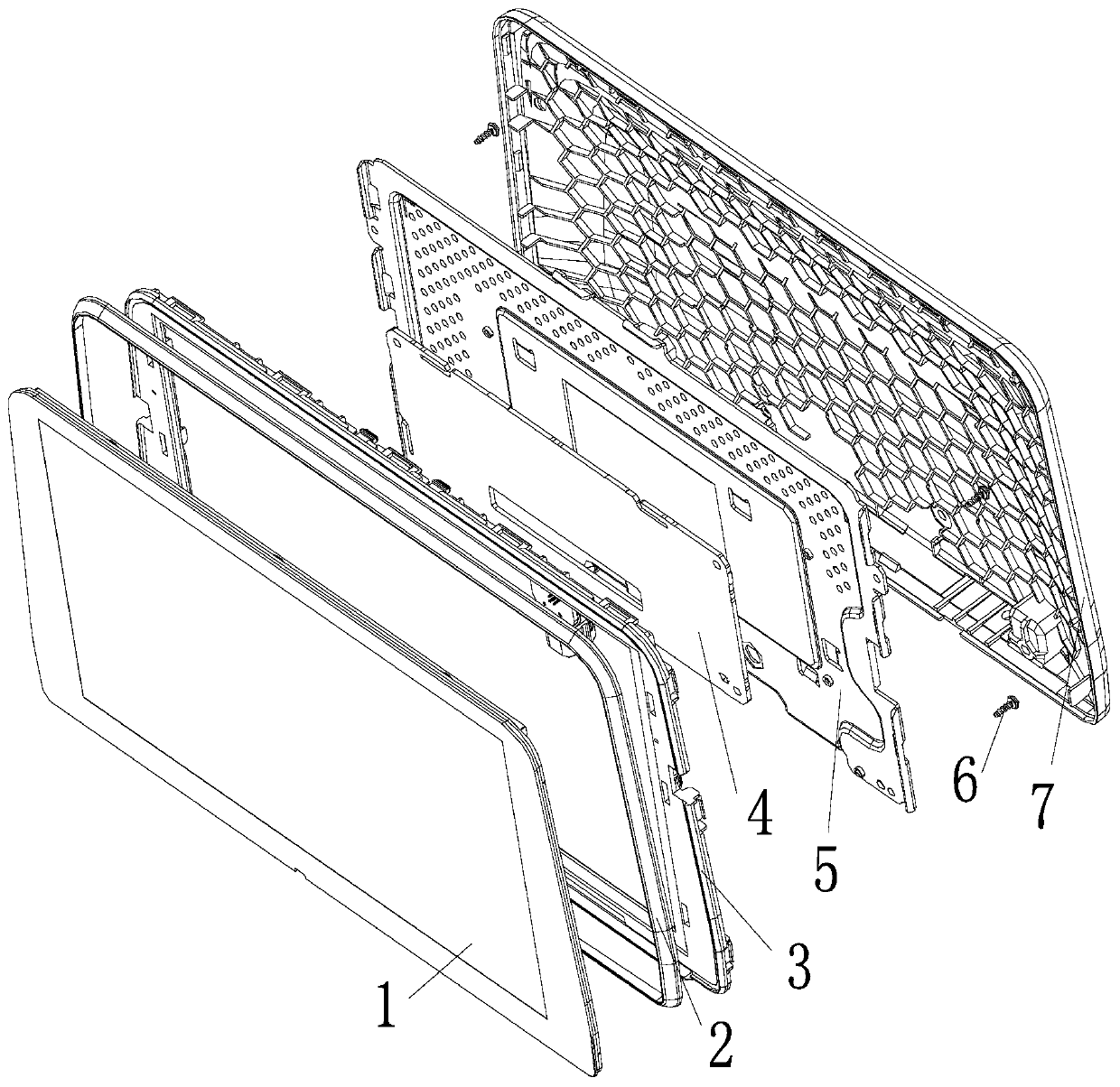

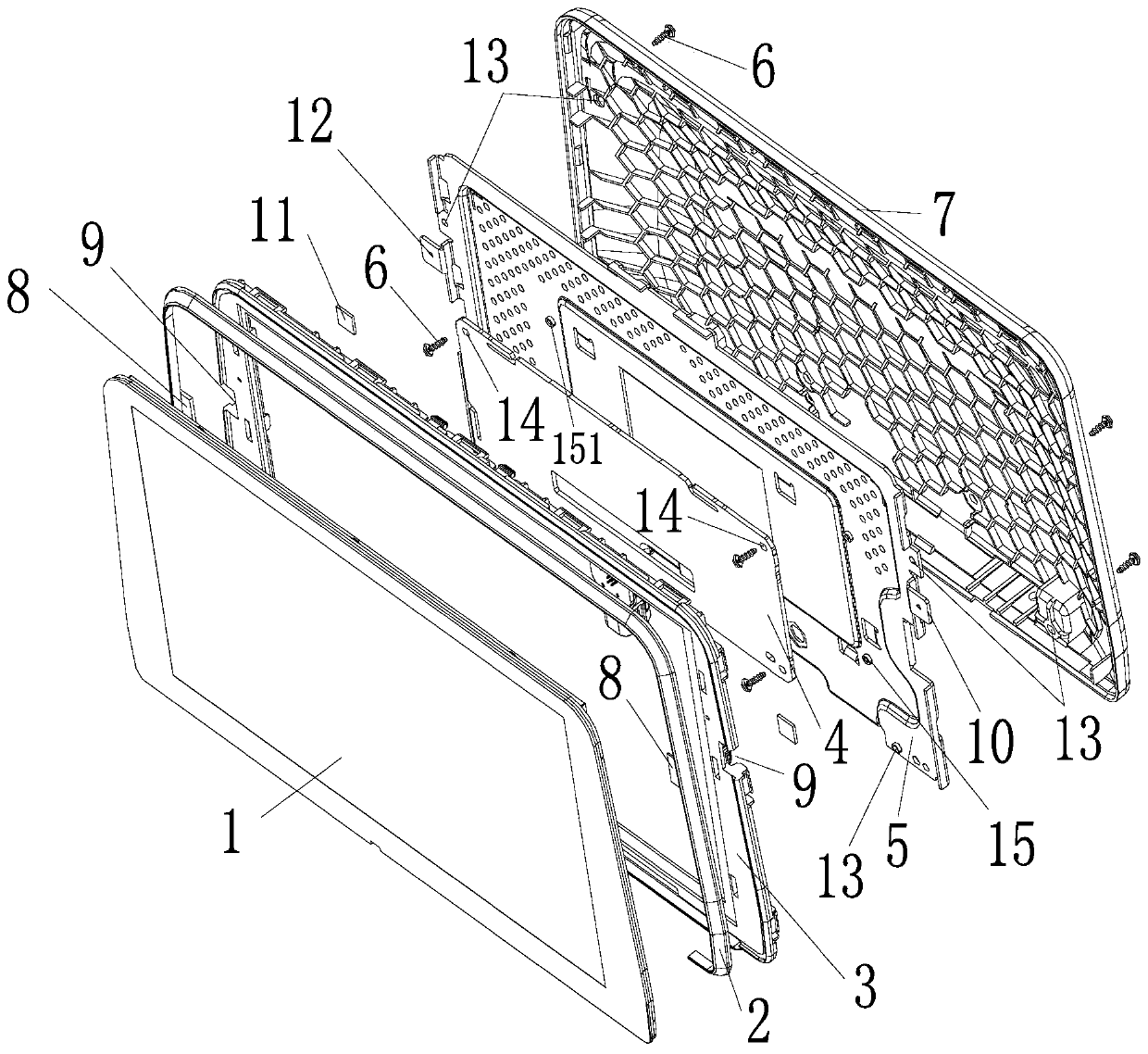

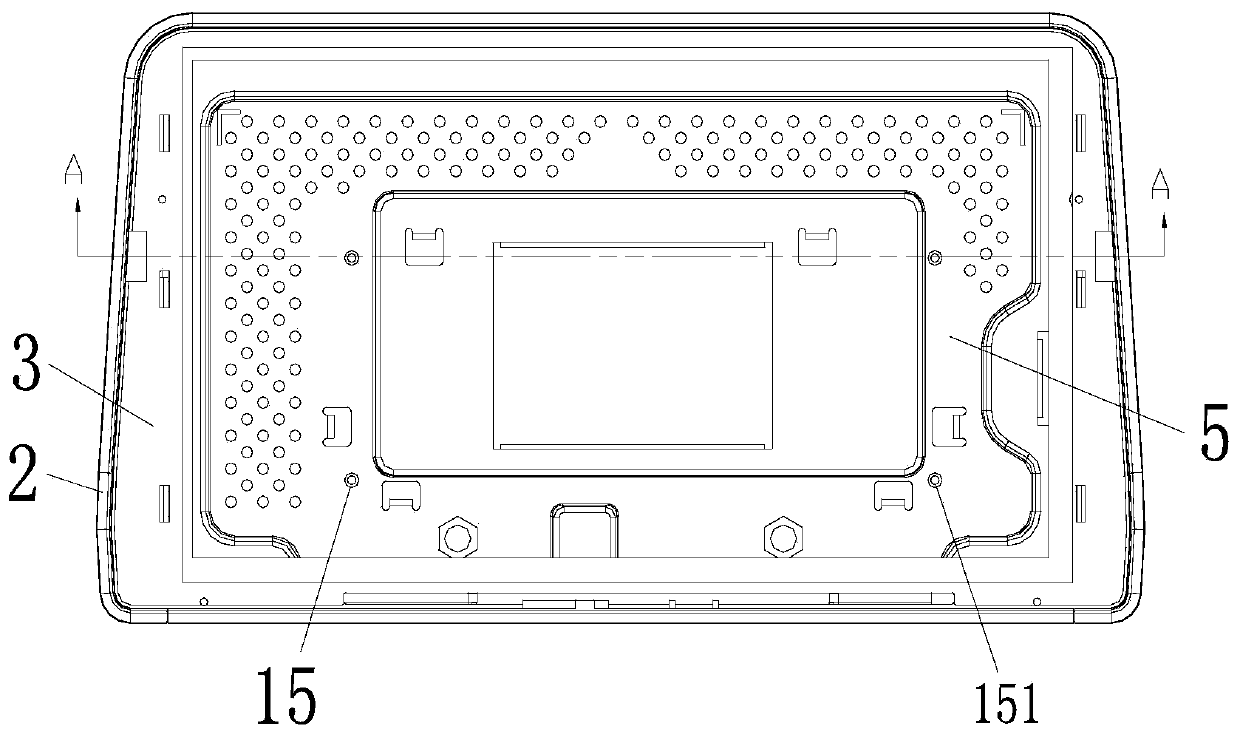

[0034] Such as Figures 2 to 5 As shown, a grounding structure of an electroplating decorative ring includes a plastic panel 3, an electroplating decorative ring 2 embedded in the outer surface of the plastic panel 3 through buckles or glue, and a driving PCB board 4 located on the back of the plastic panel 3, which is located at the driving The hardware bracket 5 on the back of the PCB board 4 locks the drive PCB board 4 to the front of the hardware bracket 5 through fixing parts such as four screws 6, and also includes a touch display screen 1 installed in front of the plastic panel 3, which is located on the back of the hardware bracket 5 The rear cover 7 is fastened to the back of the plastic panel 3 through fixing components such as four screws 6 passing through the second screw holes 13 of the rear cover 7 and the hardware bracket 5 respectively. At least two conductors 8 are arranged on the electroplating decoration ring 2, and the conductors 8 are arranged on both side...

Embodiment 2

[0041] Such as Figures 6 to 8 As shown, the difference from the above-mentioned embodiment 1 is that the conductor 8 is an elastic body 82 provided on the inner ring of the electroplated decoration ring 2 .

[0042] Furthermore, the elastic body 82 is preferably a curved structure, and the elastic body 82 can pass through the gap 9 on the plastic panel 3 , interfere with and electrically connect with the connecting body 10 provided on the hardware bracket 5 .

[0043] Further, both ends of the elastic body 82 are respectively provided with a right-angle bend, the right-angle bend at the front end is convenient to penetrate the gap 9, and the right-angle bend at the rear end is convenient to interfere with the connecting body 10, and the connecting body 10 is provided with a forward bending The mesa 101, the mesa 101 makes grounding easier and can resist the pressure of the elastic body 82 without deformation. The rest of the content is the same as that of Embodiment 1 and wi...

Embodiment 3

[0045] Such as Figures 9 to 11 As shown, different from the above-mentioned embodiment 2, the two ends of the elastic body 82 are perpendicular to each other, and its front end is connected to the electroplating decorative ring 2, and its rear end is in elastic contact with the outer surface of the forward straight part 102 of the connecting body 10 and For electrical connection, the interference of spring pressure is a, and the end of the contact surface between the straight extension part 102 and the rear end of the elastic body 82 is respectively provided with chamfers, which is convenient for assembly and electrical connection. The rest of the content is the same as that of Embodiment 2 and will not be repeated here.

[0046] In summary, adopting the technical solution of the present invention has the following beneficial effects:

[0047] The present invention solves the problem that the existing electroplating decorative ring does not have any contact with other parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com