Magnetic powder adhesive for adhesion of anisotropic magnetic powder

An anisotropic magnetic and magnetic powder technology, applied in the field of anisotropic magnets, can solve problems such as single components and functions, poor rotation of magnetic powder particles, and unsatisfactory magnetic field orientation effects, so as to ensure comprehensive magnetic properties, improve lubricity, The effect of improving the magnetic field orientation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

[0019] The magnetic powder adhesive for bonding anisotropic magnetic powders of the present invention is prepared by mixing adhesives, curing agents, accelerators and additives, and is used to coat and connect magnetic powder particles when preparing magnetic powders of various magnets.

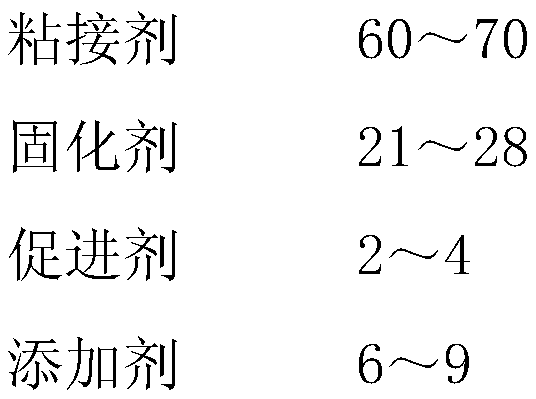

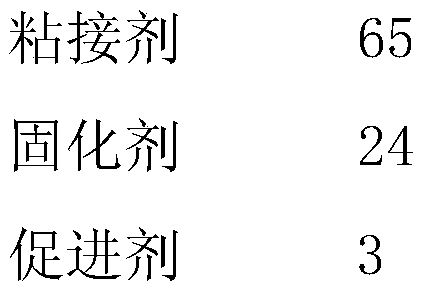

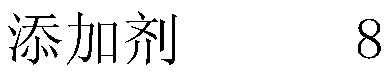

[0020] The magnetic powder glue includes the following components in weight percent: 60-70 adhesives, 21-28 curing agents, 2-4 accelerators and 6-9 additives. In this embodiment, preferably 65% of the adhesive, 24% of the curing agent, 3% of the accelerator, and 8% of the additive, and the above components are mixed to form a magnetic powder adhesive mixture. Wherein, the adhesive may be one of rubber, plastic, and resin. In this embodiment, the resin is epoxy resin, which is the main component of the magnetic powder glue, and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com