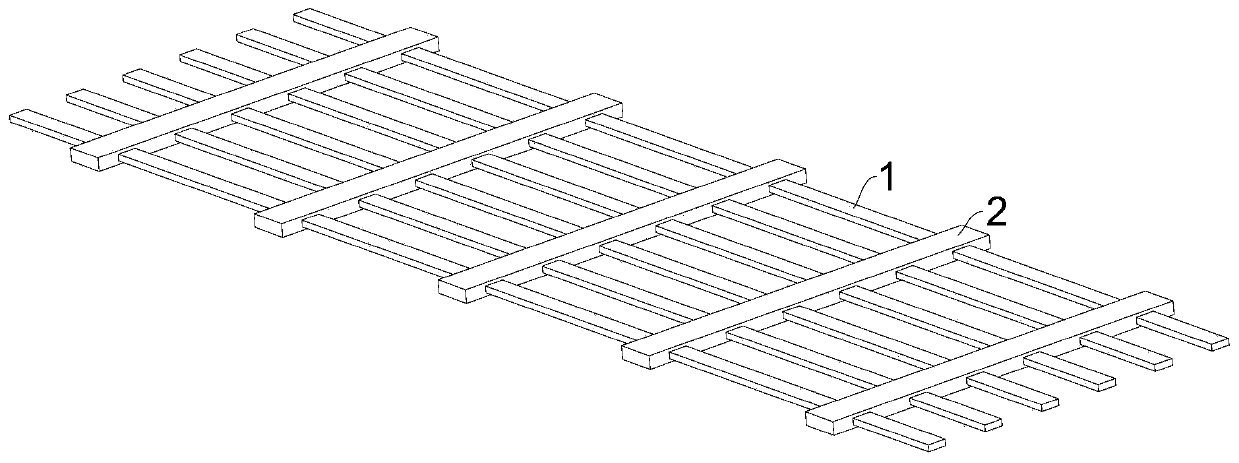

High-strength one-way geogrid and preparation method

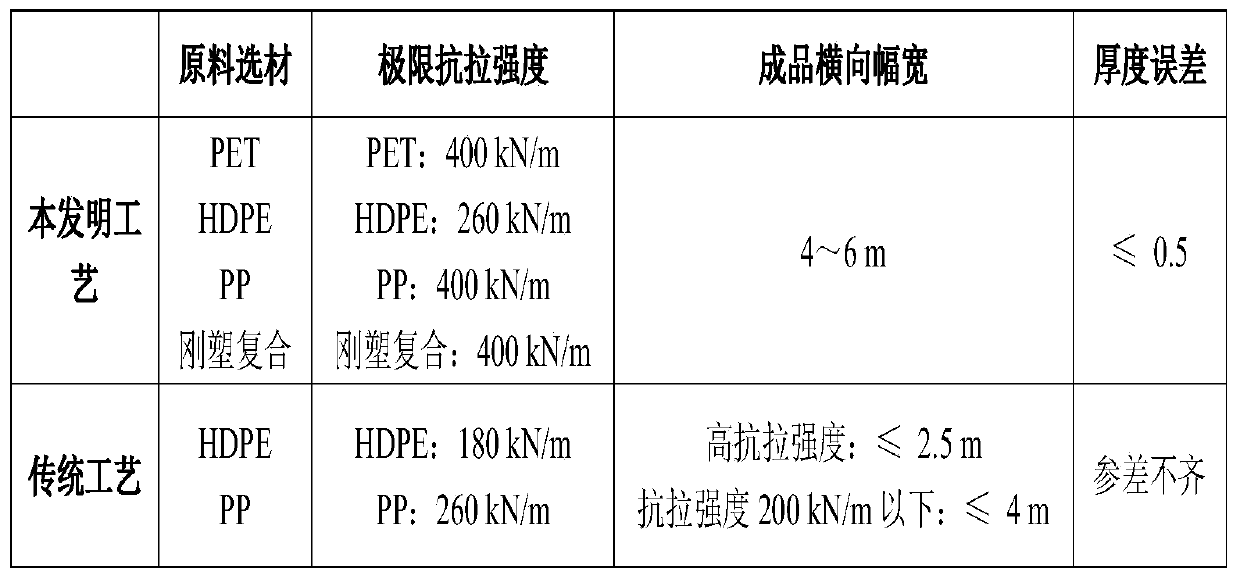

A geogrid, high-strength technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problem of insufficient utilization of material physical properties, longitudinal skew, tensile strength and unit Problems such as uneven length and weight, to achieve the effects of improving product economic benefits, diversifying raw material selection, good creep resistance and UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a technical solution: a method for preparing a high-strength unidirectional geogrid, comprising the following steps:

[0041] Preparation of longitudinal ribs: use a dehumidifier to dehumidify the rib raw materials for 5 hours, and the moisture content of the dehumidified raw materials is less than 50PPM; use a parallel twin-screw extruder to plasticize and extrude the dehumidified raw materials at a high temperature of 260°C to form a rectangle The embryo tape; after the embryo tape is cooled by 50 ℃ constant temperature water, it is sent to the electric heating oven for the first heating, and the temperature of the electric heating oven is 130 ℃; The stretching ratio is 1:2); the stretched embryo tape is sent to the electric oven for the second heating, and the temperature of the electric oven is 130°C; the heated embryo tape is subjected to secondary stretching (stretching) The ratio is 1:2), and at the same time, the embossing roller is used...

Embodiment 2

[0046] This embodiment provides a technical solution: a method for preparing a high-strength unidirectional geogrid, comprising the following steps:

[0047] Preparation of longitudinal ribs: use a dehumidifier to dehumidify the rib raw materials for 5.5 hours, and the moisture content of the dehumidified raw materials is less than 50PPM; use a parallel twin-screw extruder to plasticize and extrude the dehumidified raw materials at a high temperature of 270°C to form a rectangle The embryo tape; after the embryo tape is cooled by 55 ℃ constant temperature water, it is sent to the electric heating oven for the first heating, and the temperature of the electric heating oven is 140 ℃; The stretch ratio is 1:2.5); the stretched embryo tape is sent to the electric oven for the second heating, and the temperature of the electric oven is 140°C; the heated embryo tape is subjected to secondary stretching (stretching) The ratio is 1:2.5), and the embossing roller is used to emboss the ...

Embodiment 3

[0052] This embodiment provides a technical solution: a method for preparing a high-strength unidirectional geogrid, comprising the following steps:

[0053] Preparation of longitudinal ribs: use a dehumidifier to dehumidify the rib raw materials for 6 hours, and the moisture content of the dehumidified raw materials is less than 50PPM; use a parallel twin-screw extruder to plasticize and extrude the dehumidified raw materials at a high temperature of 280°C to form a rectangle The embryo tape; after the embryo tape is cooled by 60 ℃ constant temperature water, it is sent to the electric oven for the first heating, and the temperature of the electric oven is 150 ℃; the heated embryo tape is stretched by a stretching tractor The stretch ratio is 1:3); the stretched embryo tape is sent to the electric oven for the second heating, and the temperature of the electric oven is 150°C; the heated embryo tape is subjected to secondary stretching (stretching) The ratio is 1:3), and the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com