Engine cooling system water way flushing tool and method

An engine cooling and engine technology, applied in engine cooling, engine components, machines/engines, etc., can solve the problems of low test efficiency, increase test cost, unfavorable foreign matter discharge, etc., achieve high test flushing efficiency, reduce test cost, Time-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

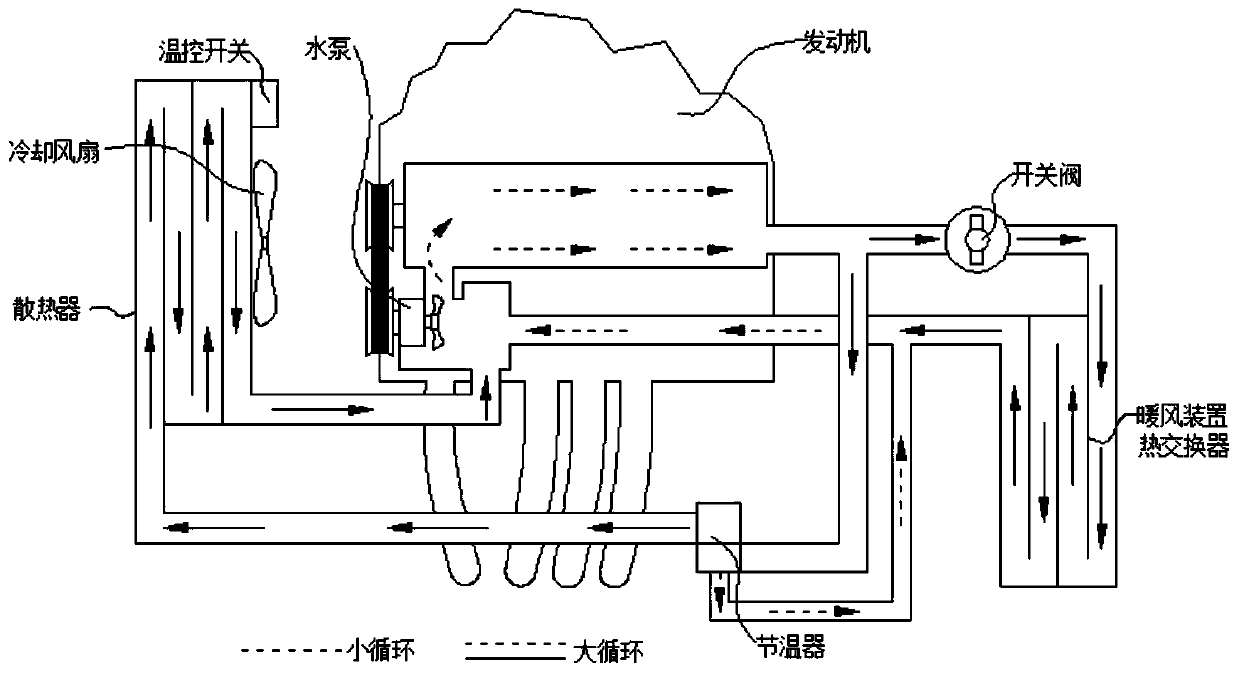

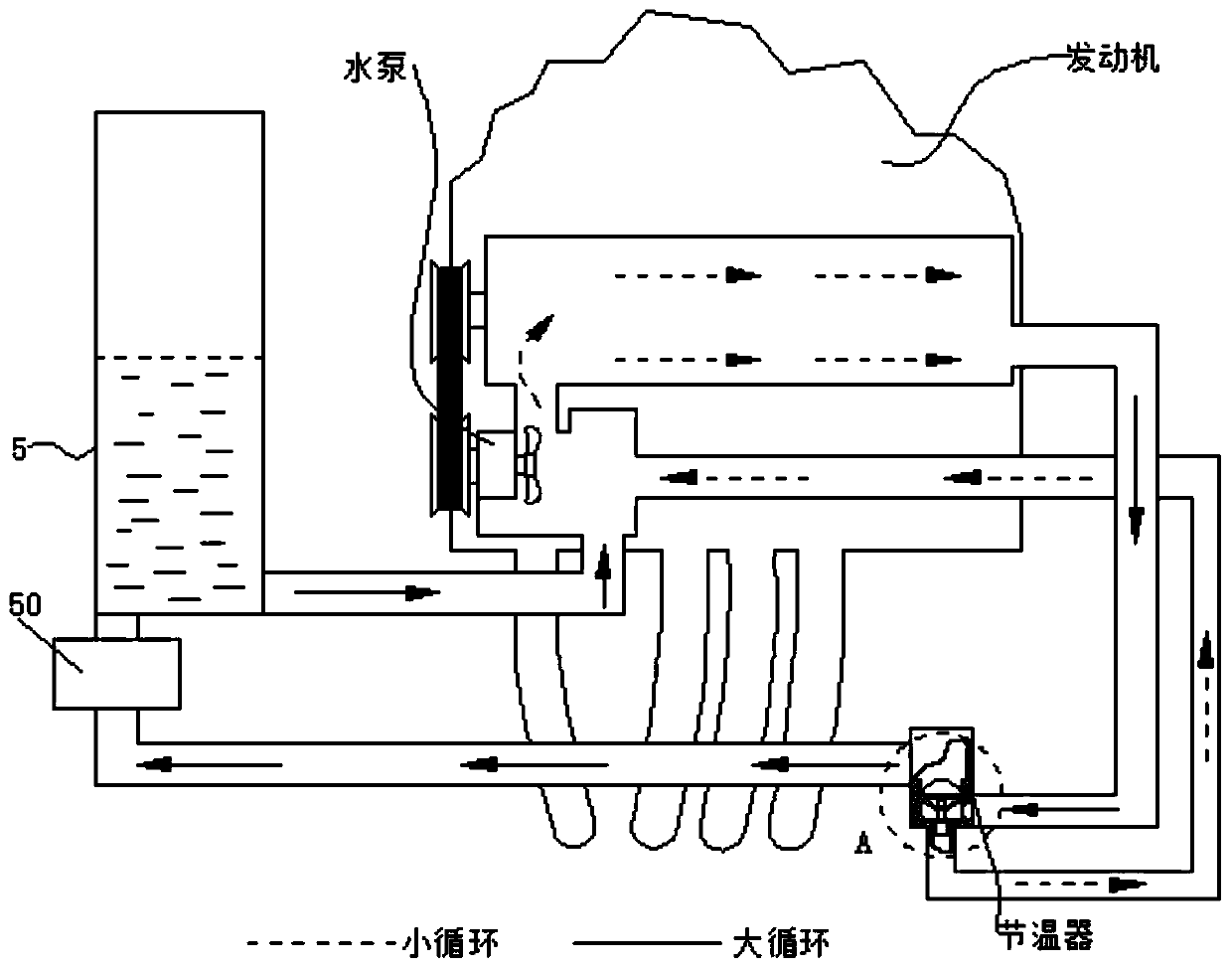

[0045] The engine cooling system waterway flushing tool replaces the radiator of the original engine cooling system with a water tank 5 for storing coolant, and then removes the temperature control system structure of the paraffin spring inside the traditional thermostat and replaces it with a symmetrical square platform Structural thermostat sealing ring 2 ensures that the large cycle of the cooling system is turned on and the small cycle is closed during the test. Under the action of the water pump, the starting water pump can be driven by an external power supply. At this time, the engine does not turn, and the starting water pump It is also possible to use an external power supply to drive the engine flywheel, so that the engine can be run cold for testing, and the coolant will take the foreign matter in the engine cooling water cavity or water channel out of the engine to achieve the purpose of flushing.

Embodiment 2

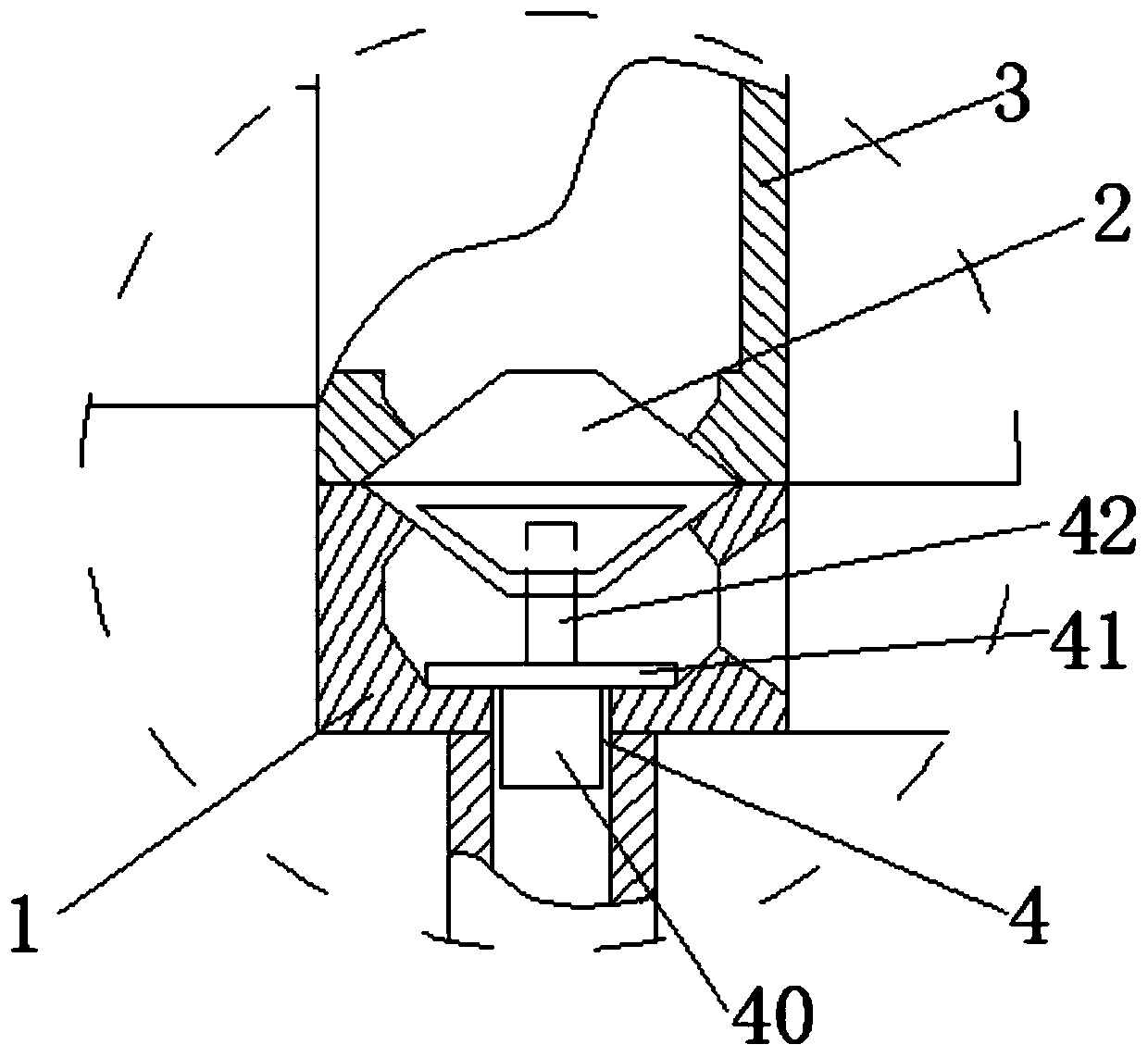

[0047] The water inlet and outlet of the water tank 5 are equipped with a filter element 50, which realizes the filtration of the foreign matter brought out by the coolant from the engine cooling water chamber or water channel; the thermostat cover 3 is fastened on the thermostat seat 1, and the A thermostat sealing ring 2 is arranged between the thermostat seat 1 and the thermostat cover 3, and the thermostat sealing ring 2 is a symmetrical quadrangular platform structure, which ensures the installation of the thermostat seat 1 and the thermostat cover 3 After completion of sealing; the bottom of the thermostat seat 1 is provided with diversion water plug tooling 4, and the bottom of the diversion water plug tooling 4 is a plunger 40, the middle is a retaining plate 41, the top is a pin 42, and the pin 42 is inserted into the joint The thermostat sealing ring 2 ensures the stability of the diversion water blocking tooling 4 under the impact of the large-circulation coolant flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com