Online measuring device for icing strength on surfaces of materials and real-time monitoring system for icing process

A measuring device and real-time monitoring technology, applied in the direction of measuring device, analyzing materials, using mechanical devices, etc., can solve problems such as test data distortion, and achieve the effect of ensuring accuracy, simple structure, and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

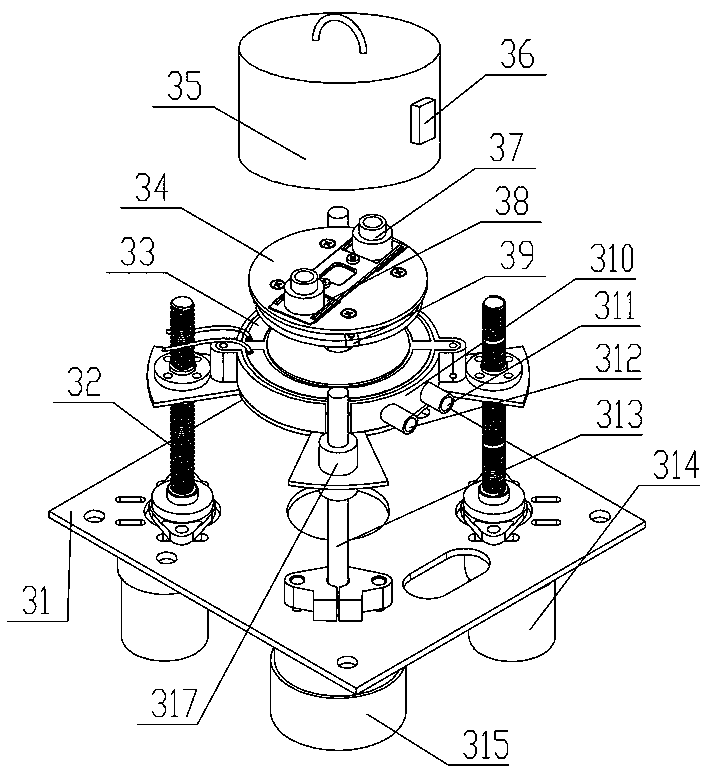

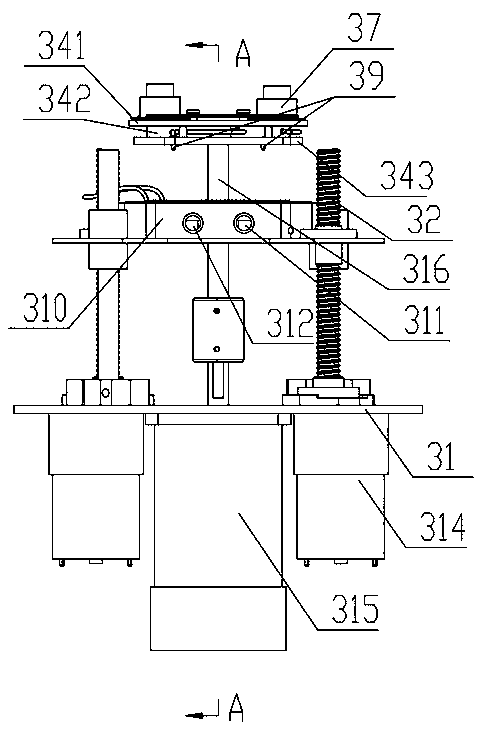

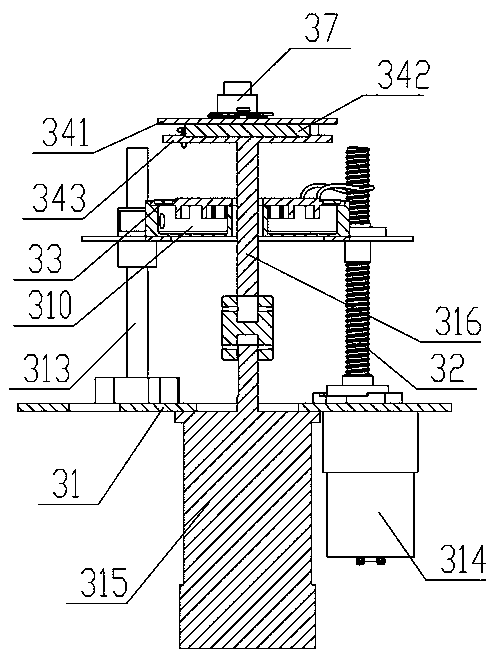

[0034] see Figure 1-5 , the present embodiment material surface icing intensity online measurement device includes a centrifugal test module and a data acquisition module, the centrifugal test module includes a fixed bracket 31 arranged from bottom to top, an annular water cooling box 310, a sample turntable 34 and an ice coating mold 37, The fixed bracket 31 is equipped with a lifting drive mechanism and a guide rod 313, and the annular water cooling box 310 is equipped with a guide sleeve 317 matched with the guide rod 313. The annular water cooling box 310 is connected with the lifting driving mechanism, and the fixed bracket 31 is also equipped with a step The motor 315, the output shaft 316 of the stepper motor 315 passes through the annular water cooling box 310 and is fixedly connected to the sample turntable 34. The sample turntable 34 includes a lower heat conduction plate 343, a semiconductor cooling plate 342, and an upper heat conduction plate 341 fixedly connected...

Embodiment 2

[0046] Comparison of freezing time of static water droplets on the surface of different wettability materials

[0047] In this example, the online real-time detection system in Example 1 was used to compare and analyze the static freezing process of water droplets on the surface of hydrophilic samples (CA=80°), hydrophobic samples (CA=140°) and superhydrophobic samples (CA=160°). Before the experiment, the sample is first fixed on the slot 38 of the sample turntable, and then a drop of about 10 μL of water is dropped on the surface of the sample to be tested with a needle. The temperature in the test chamber 2 is set to 0°C, the relative humidity is 65%, and the temperature of the sample turntable 34 is set to minus 5°C. At the beginning stage, the water droplets are all transparent. As time goes on, the temperature of the water droplets begins to decrease. Once they freeze, the droplets become cloudy and no longer transparent. Due to the obvious density difference between th...

Embodiment 3

[0049] Comparison of energy consumption for melting ice on the surface of different wettability materials

[0050] This example compares and analyzes the energy consumption of melting ice after water droplets freeze on the surface of hydrophilic samples (CA=80°), hydrophobic samples (CA=140°) and superhydrophobic samples (CA=160°). First carry out the static water droplet freezing process according to the process of Example 2, then reversely energize the semiconductor cooling chip 342 in the sample turntable 34 to heat the ice beads (the upper end is the hot end, and the lower end is the cold end), and record the time required for the ice melting process and energy consumption. Each experiment was repeated three times to obtain the average value. As shown in the table below, for hydrophilic samples, the average time consumption is 27s, and the average power consumption is 0.028Wh; for hydrophobic samples, the average time consumption is 56s, and the average power consumption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com