Combined glue spray opening

A combined glue-spraying technology, which is applied in the direction of spraying devices, liquid spraying devices, evaporator accessories, etc., can solve the problems that affect the long-term stable operation of equipment, blockage, and high energy consumption of the device, so as to reduce the amount of rubber debris and prolong cleaning. Glue cycle, the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

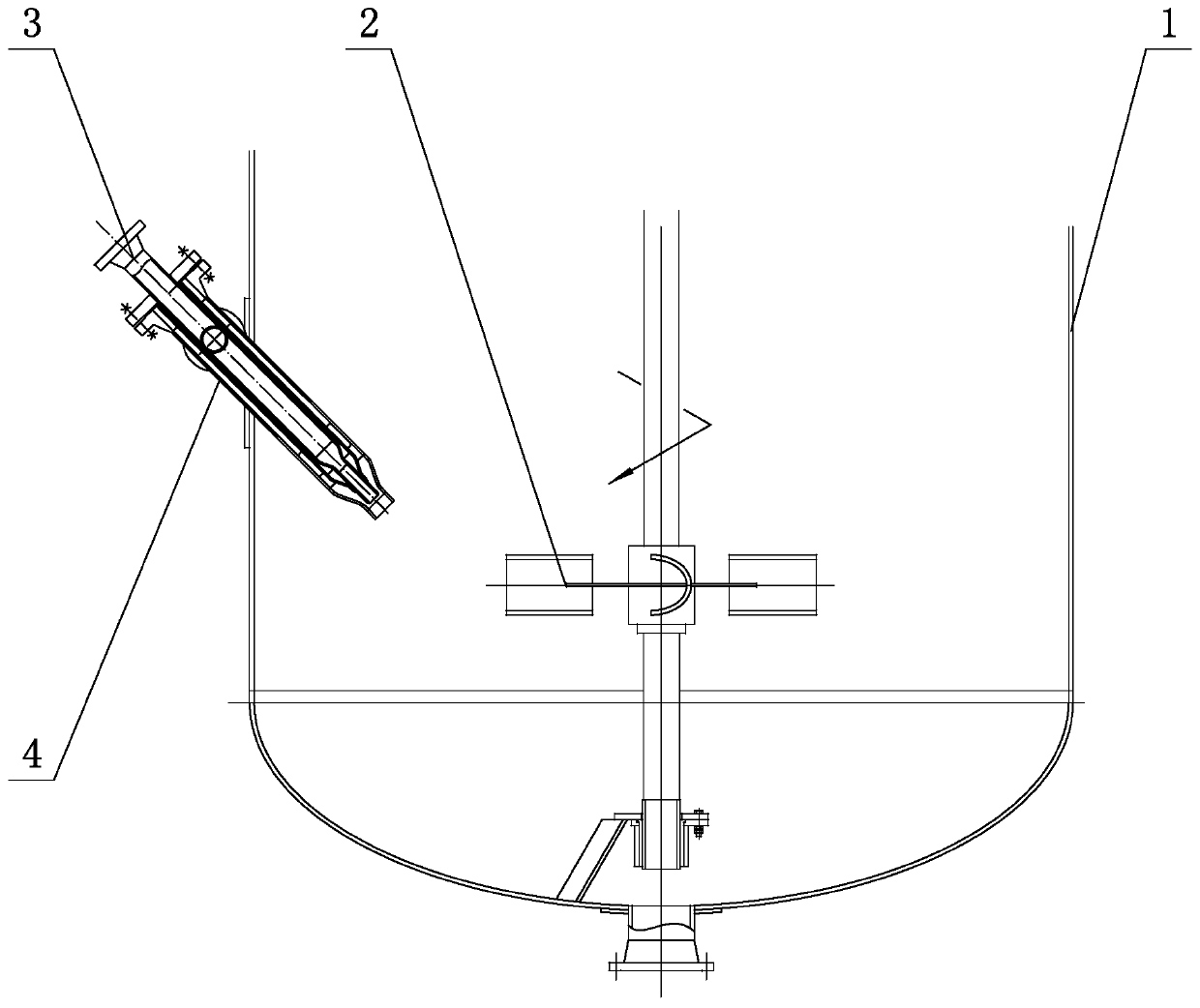

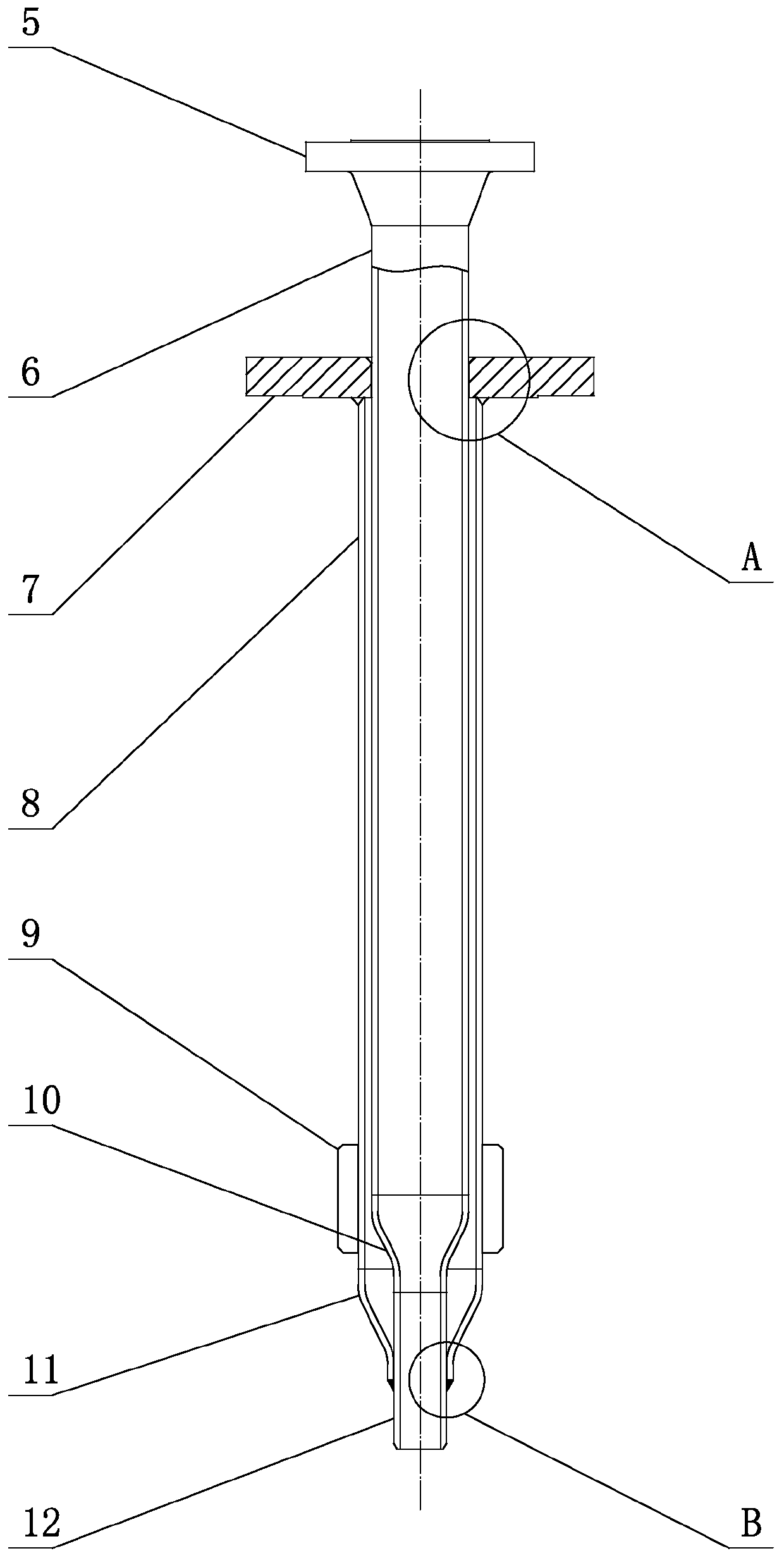

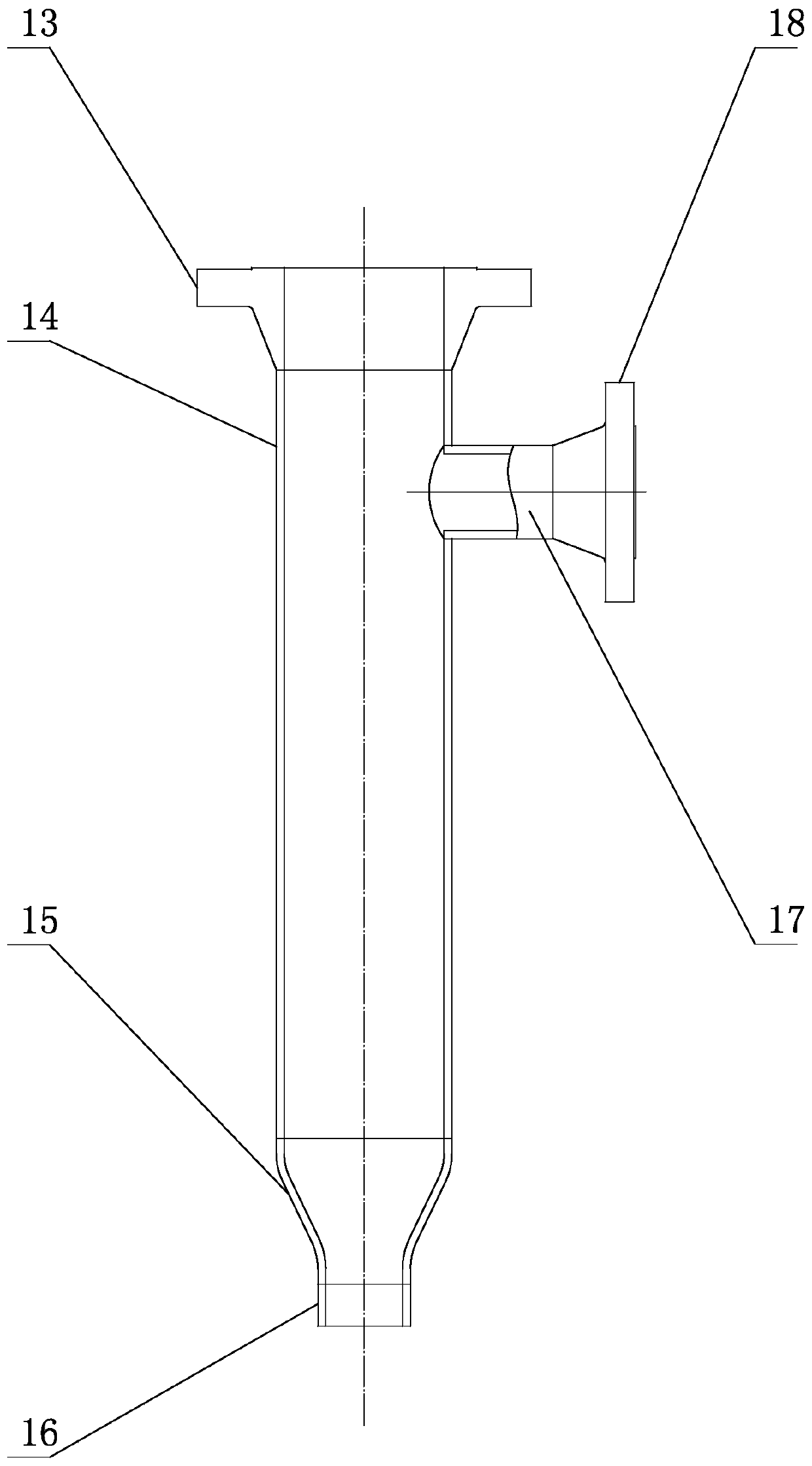

[0026] Such as Figure 1-Figure 5 , the combined glue spraying port of the present invention is installed on the kettle body 1 of the coagulation kettle, and includes a glue spraying group pipe 4 and a secondary steam pipe 3, and the glue spraying group pipe 4 is set on the outer periphery of the secondary steam pipe 3, The outer wall of the glue spraying group pipe 4 is fixedly connected with the kettle body 1 of the coagulation kettle, the glue spraying group pipe 4 and the secondary steam pipe 3 are coaxial, and the glue spraying group pipe 4 and the secondary steam pipe 3 are arranged obliquely, and the glue spraying port is opened Orienting obliquely downward; the secondary steam pipe 3 includes a steam connection flange 5 and a steam pipe 6, the steam connection flange 5 is fixed at the top inlet of the steam pipe 6, and the upper part of the steam pipe 6 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com