Passivation method for heavy metal contaminated farmland soil

A technology for polluted soil and heavy metals, applied in the restoration of polluted soil and other directions, can solve the problems of difficulty in distinguishing between the actual effect and interaction of passivating agents, excess, and difficulty in further improving the removal effect of heavy metals, so as to achieve the effect of soil passivation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

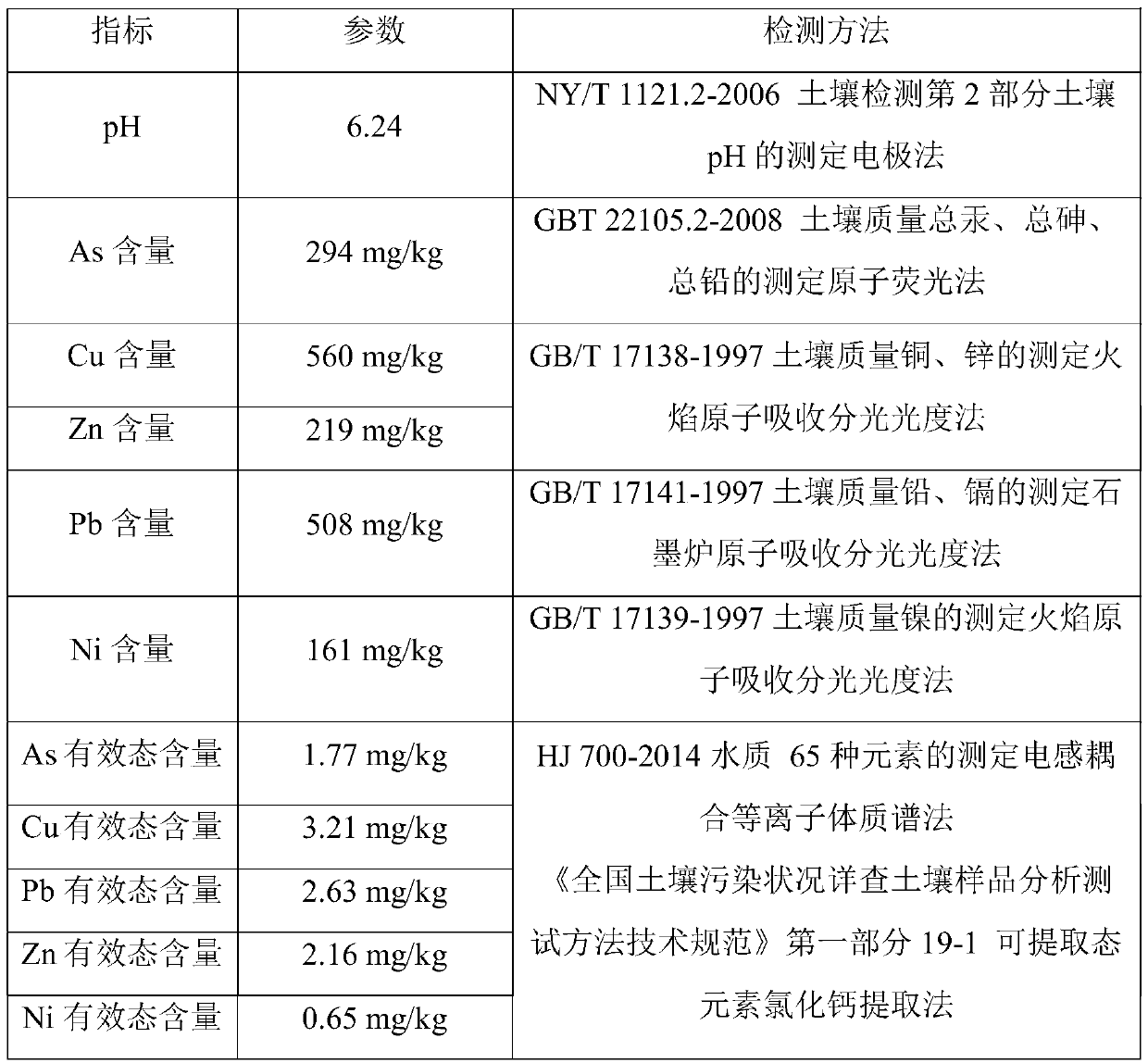

Image

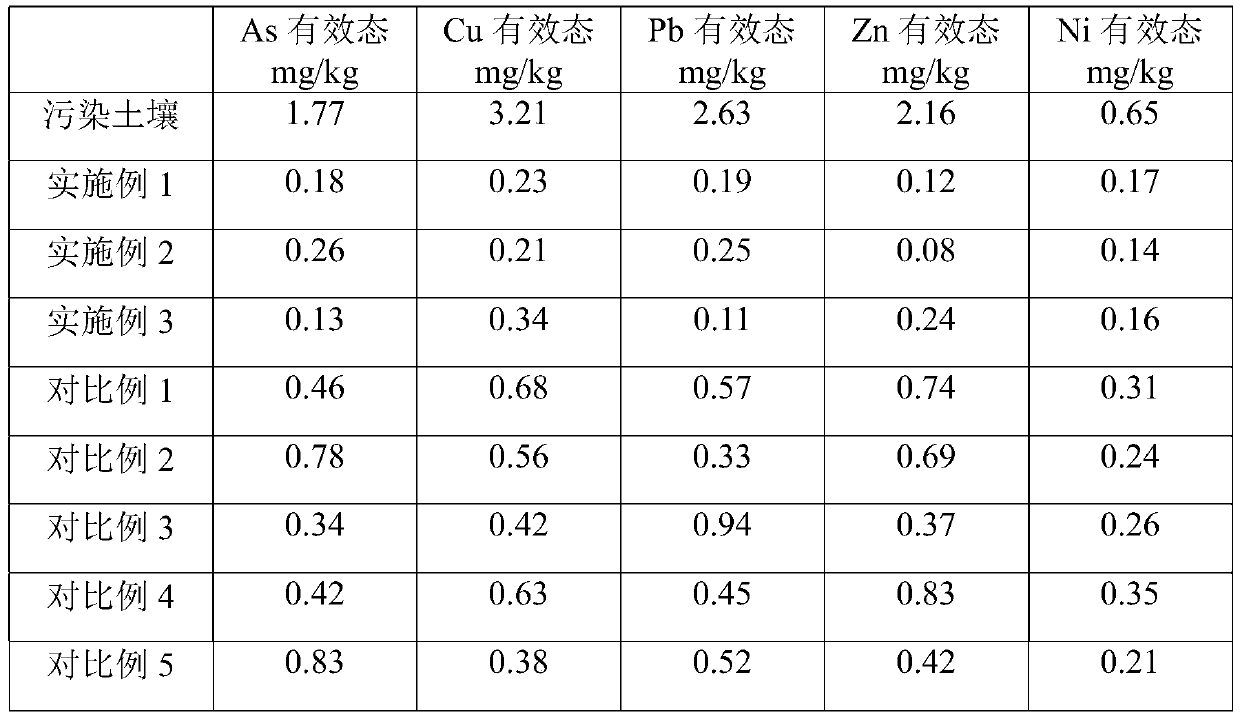

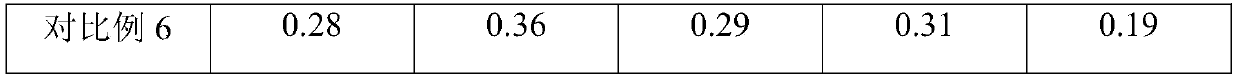

Examples

Embodiment 1

[0029] 1) Add 4g of ferric oxide, 2g of calcium carbonate, and 2g of calcium hydroxyphosphate into 1kg of heavy metal-contaminated soil, stir evenly, and let stand for 20 minutes;

[0030] 2) Add 5 g of plant ash and 10 g of calcium-based bentonite to the mixture obtained in step 1), stir evenly, and let stand for 20 minutes;

[0031] 3) Spray tap water into the mixture obtained in step 2), adjust the water content by weight to 30%, stir evenly, and let it stand for 3 days for maintenance.

Embodiment 2

[0033] 1) Add 3g of ferric oxide, 3.5g of calcium carbonate and 1.5g of calcium hydroxyphosphate into 1kg of heavy metal-contaminated soil, stir evenly, and let stand for 30 minutes;

[0034]2) Add 2 g of plant ash and 13 g of calcium-based bentonite to the mixture obtained in step 1), stir evenly, and let stand for 10 minutes for maintenance;

[0035] 3) Spray tap water into the mixture obtained in step 2), adjust the water content by weight to 30%, stir evenly, and let it stand for 3 days for maintenance.

Embodiment 3

[0037] 1) Add 4.5g of ferric oxide, 1g of calcium carbonate and 2.5g of calcium hydroxyphosphate into 1kg of heavy metal-contaminated soil, stir evenly, and let stand for 10 minutes;

[0038] 2) Add 9g of plant ash and 6g of calcium-based bentonite to the mixture obtained in step 1), stir evenly, and let it stand for curing for 30 minutes;

[0039] 3) Spray tap water into the mixture obtained in step 2), adjust the water content by weight to 30%, stir evenly, and let it stand for 3 days for maintenance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com