Fine wire loop device

A looper device and looper technology, applied to bending workpieces, metal processing equipment, metal rolling, etc., can solve environmental hazards, high energy consumption, and cannot completely eliminate cold drawing process annealing, subsequent pickling and lead bath links and other problems, to achieve the effect of convenient adjustment, small space occupation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred implementation of the device of the present invention will be further described in detail below in conjunction with the accompanying drawings.

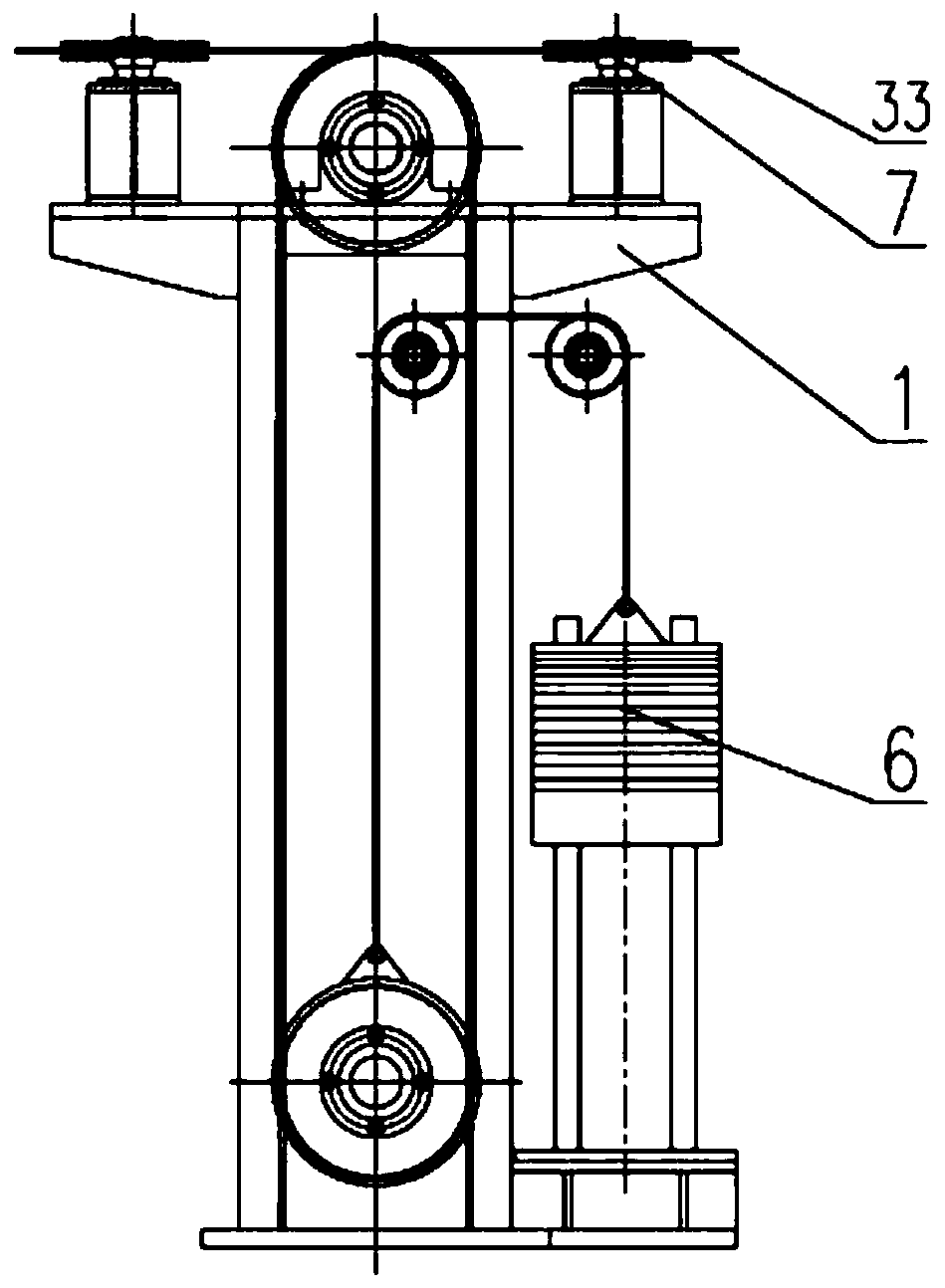

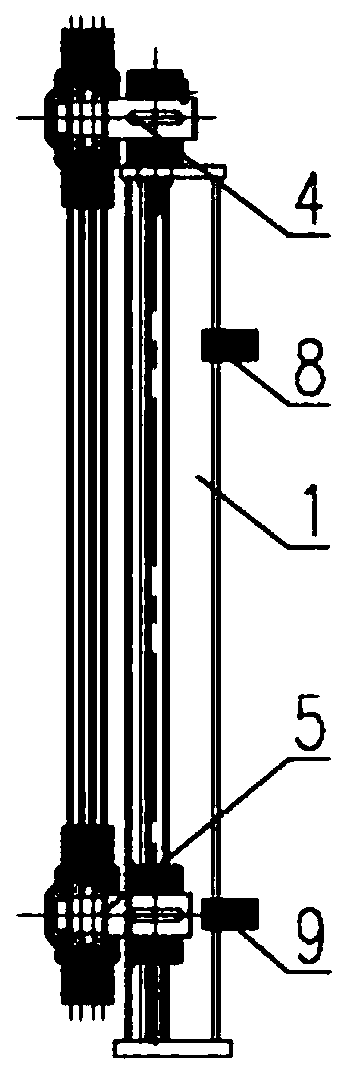

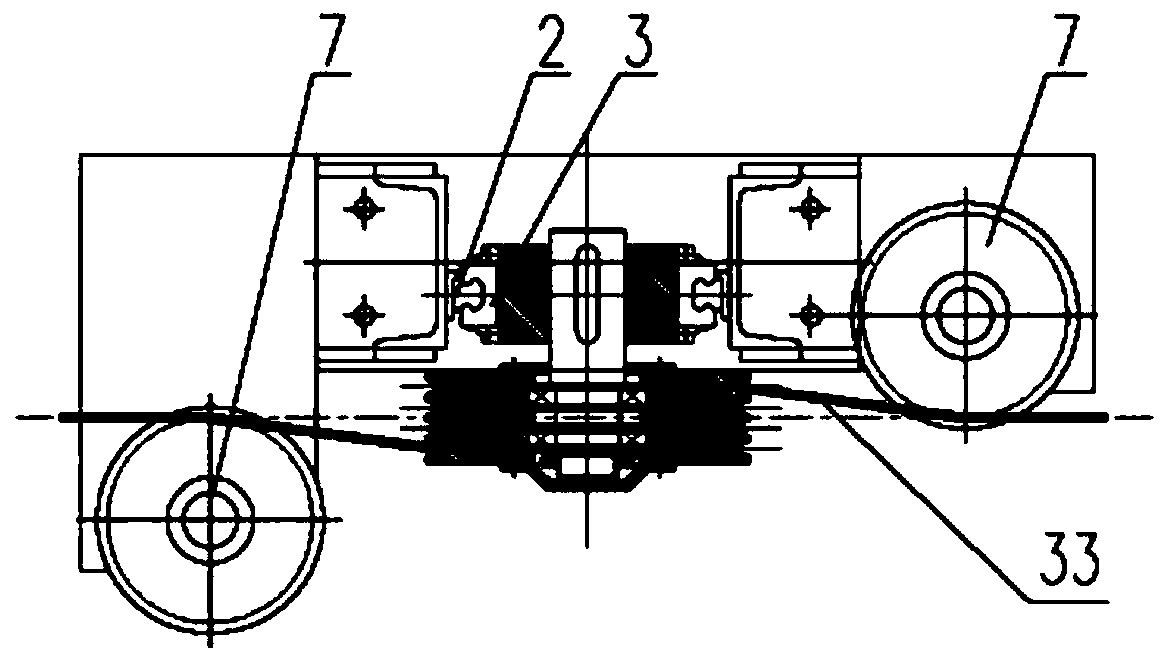

[0028] like Figure 1-3 As shown, a filament looper device includes a looper seat 1, a guide rail 2, a slider 3, a fixed looper wheel 4, a moving looper wheel 5, a balance device 6, a guide wheel 7, a detection device-8, a detection device Apparatus 29.

[0029] The looper seat 1 is installed on the concrete foundation, and other parts are installed on the looper seat 1, which are the load-bearing and stressed parts of the equipment.

[0030] like Figure 4 As shown, the guide rail 2 is installed on the inner side of the looper seat 1, and the slide block 3 is installed on the guide rail 2 by ferrule, and can slide up and down along the guide rail 2.

[0031] like Figure 5 As shown, the fixed looser wheel 4 is installed on the top of the looser seat 1, and the fixed looser wheel 4 includes a base-10, a shaft-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com