In-use elevator guide rail straightness detection system and method

A technology of elevator guide rail and detection system, which is applied in the direction of measuring device, surveying and navigation, measuring inclination, etc., to achieve the effect of convenient and easy detection and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

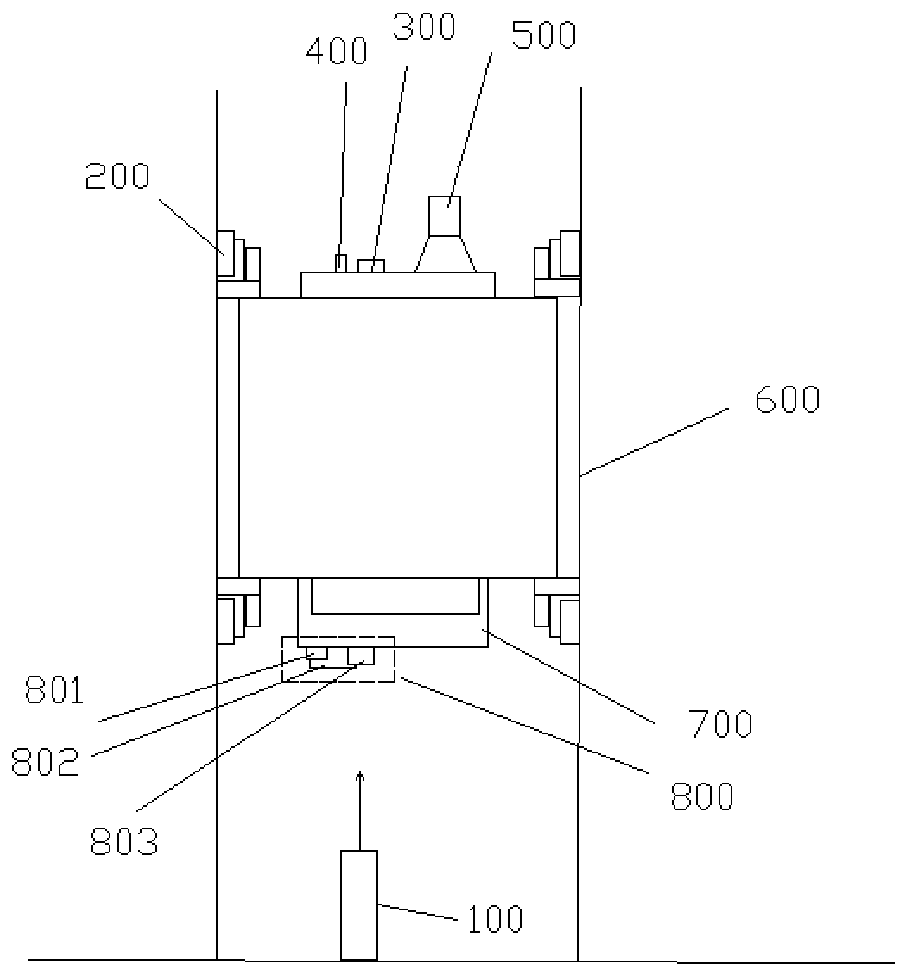

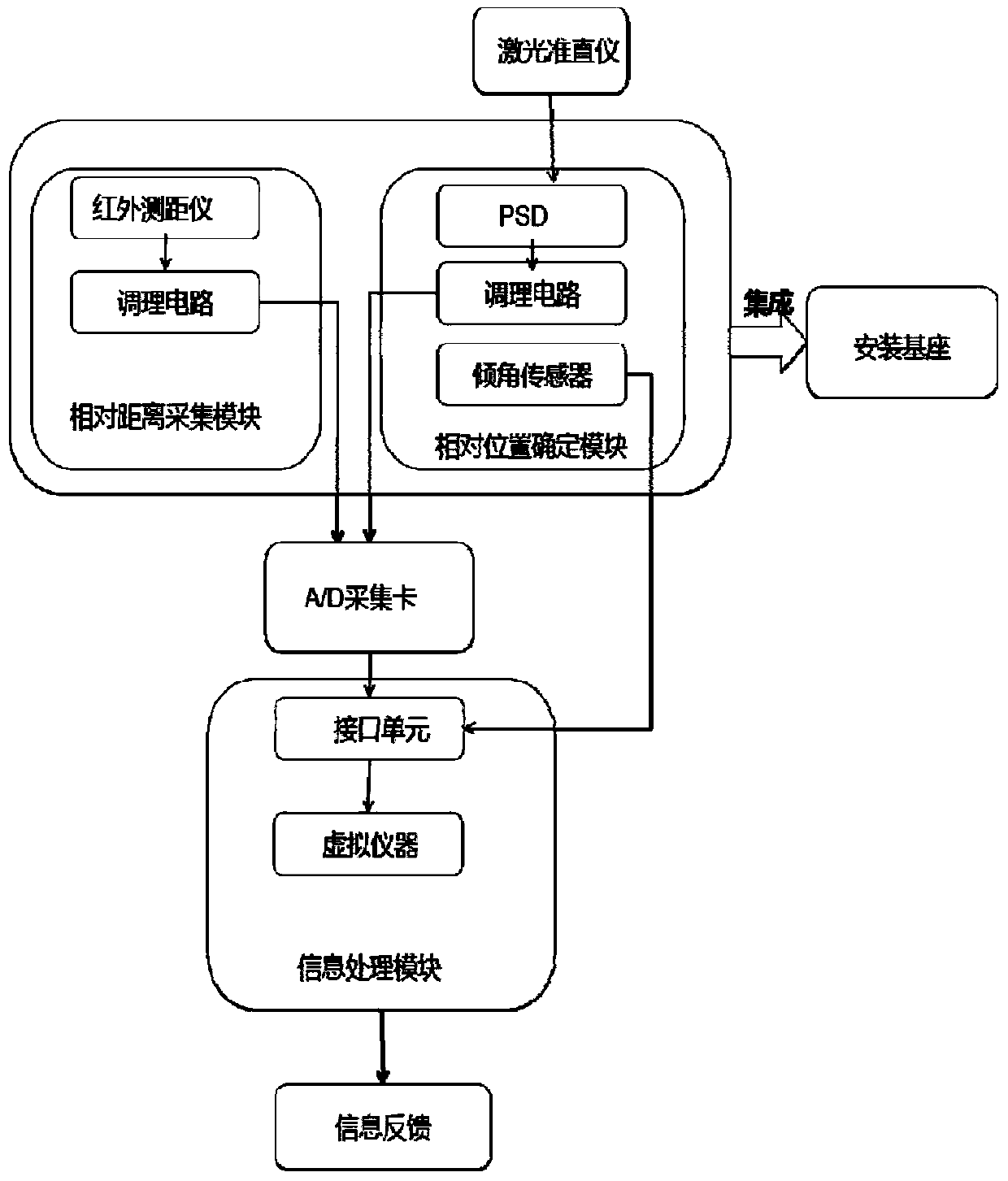

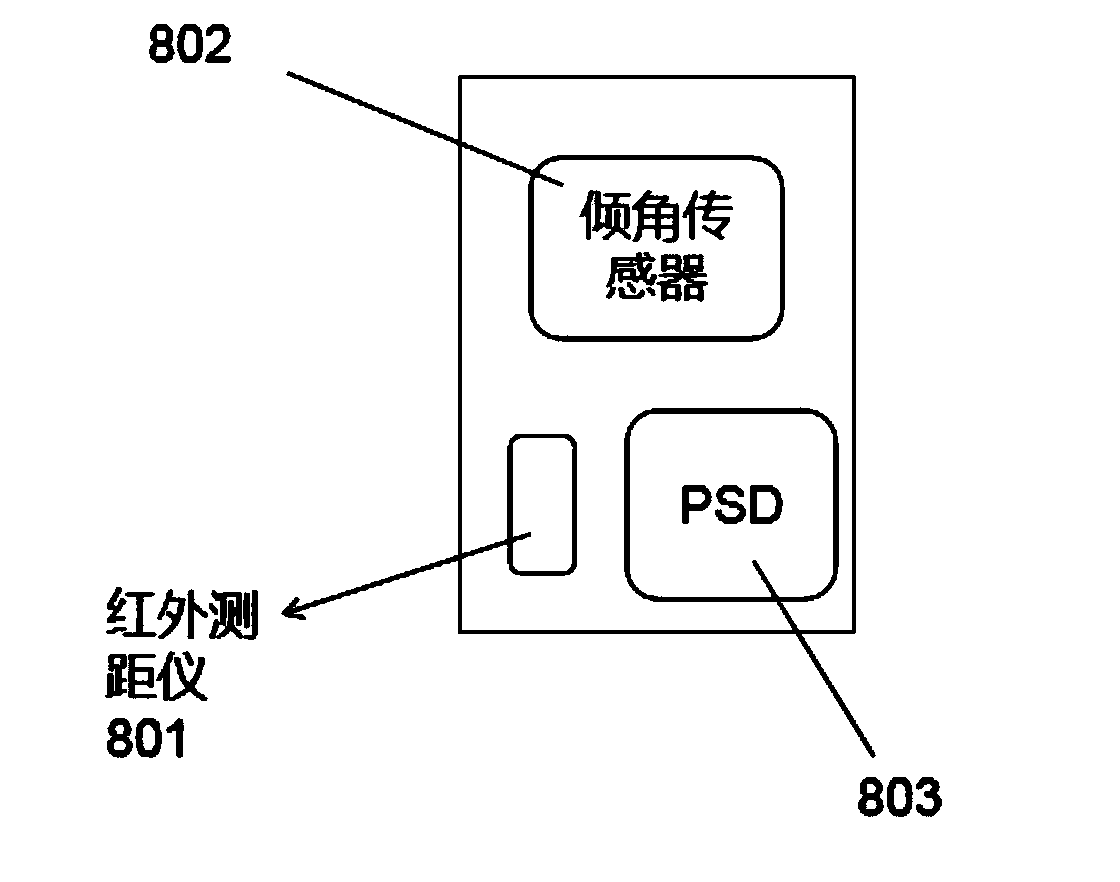

[0027] combine Figure 1 to Figure 3 , the present invention is an elevator guide rail straightness detection system in use, comprising:

[0028] A stable datum establishment module, used to establish a virtual gravity line datum, to establish a datum coordinate system;

[0029] Relative distance measurement module, used to measure the distance between the module and the guide rail;

[0030] The relative position measurement module is used to determine the position information of the car relative to the virtual gravity line;

[0031] The data collection module is used to collect the data measured by the relative distance measurement module and the relative position measurement module;

[0032] The information processing module is used to analyze and process the data collected by the data acquisition module to obtain the straightness and the horizontal vibration of the car;

[0033] A power supply module, configured to supply power to the above-mentioned modules;

[0034] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com