Permanent magnetic ferrite and permanent magnetic ferrite molding method utilizing biomass binder

A technology of permanent ferrite and molding method, which is applied in the field of permanent ferrite manufacturing, can solve harmful and unfavorable industrial production problems, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

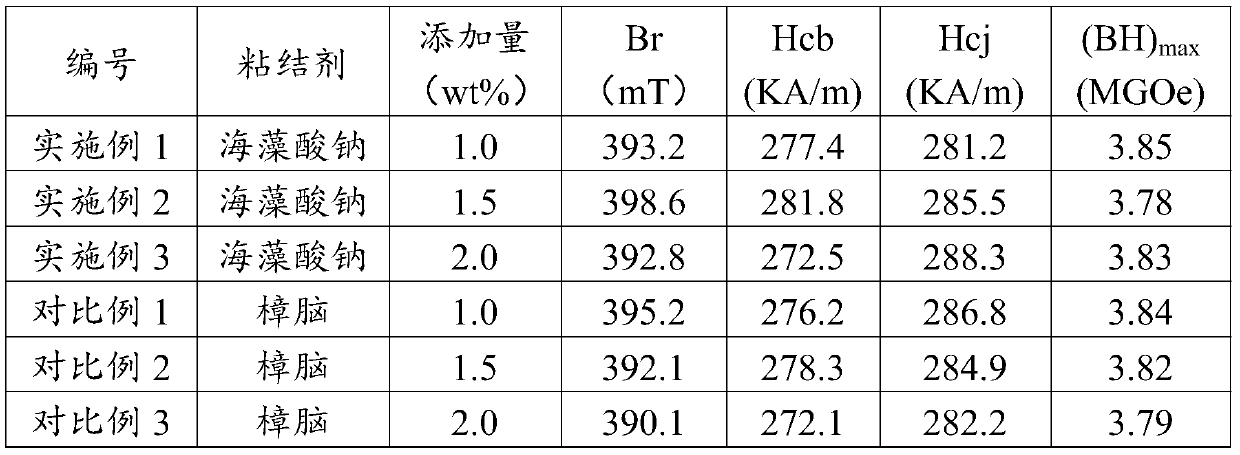

Examples

Embodiment 1

[0023] S1 Prepare sodium alginate, dissolve alginic acid in water, add dropwise sodium hydroxide solution to neutralize to pH 7, add activated carbon to absorb impurities, and obtain filtrate by suction filtration, add ethanol to the filtrate, filter the precipitated solid product, and ball mill to a particle size of 75 μm to obtain sodium alginate;

[0024] S2 prepares the concentrate, selects Y38 pre-fired fine magnetic powder on the market, mixes the pre-fired fine magnetic powder with sodium alginate, wherein sodium alginate accounts for 10wt%, pre-fired fine magnetic powder accounts for 90wt%, and evenly adds 1.2 Wt% atomized water, mixed and stirred evenly, then dispersed with high-speed dispersant;

[0025] S3 prepares the molding material, weighs the concentrated material obtained in step S2 and Y38 calcined fine magnetic powder and mixes it with a mass ratio of 1:9, then adds calcium stearate with a weight of 1.0wt% of the mixture, mixes and stirs evenly, and uses a h...

Embodiment 2

[0029] S1 Prepare sodium alginate, dissolve alginic acid in water, add dropwise sodium hydroxide solution to neutralize to pH 7, add activated carbon to absorb impurities, and obtain filtrate by suction filtration, add ethanol to the filtrate, filter the precipitated solid product, and ball mill to a particle size of 70 μm to obtain sodium alginate;

[0030] S2 prepares the concentrate, selects Y38 calcined material fine magnetic powder on the market, mixes calcined material fine magnetic powder with sodium alginate, wherein sodium alginate accounts for 15wt%, calcined material fine magnetic powder accounts for 85wt%, evenly adds 1.4 Wt% atomized water, mixed and stirred evenly, then dispersed with high-speed dispersant;

[0031] S3 prepares molding materials, weighs the concentrated material obtained in step S2 and Y38 calcined material fine magnetic powder and mixes them with a mass ratio of 1:9, then adds calcium stearate with a weight of 0.8wt% of the mixture, mixes and st...

Embodiment 3

[0035] S1 Prepare sodium alginate, dissolve alginic acid in water, add dropwise sodium hydroxide solution to neutralize to pH 7, add activated carbon to absorb impurities, and obtain filtrate by suction filtration, add ethanol to the filtrate, filter the precipitated solid product, and ball mill to a particle size of 60 μm to obtain sodium alginate;

[0036] S2 prepares the concentrate, selects Y38 pre-fired fine magnetic powder on the market, mixes the pre-fired fine magnetic powder with sodium alginate, wherein sodium alginate accounts for 20wt%, pre-fired fine magnetic powder accounts for 80wt%, and evenly adds 1.6 Wt% atomized water, mixed and stirred evenly, then dispersed with high-speed dispersant;

[0037] S3 prepares molding materials, weighs the concentrated material obtained in step S2 and Y38 pre-fired fine magnetic powder and mixes it with a mass ratio of 1:9, then adds calcium stearate with a weight of 0.7wt% of the mixture, mixes and stirs evenly, and uses a hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com