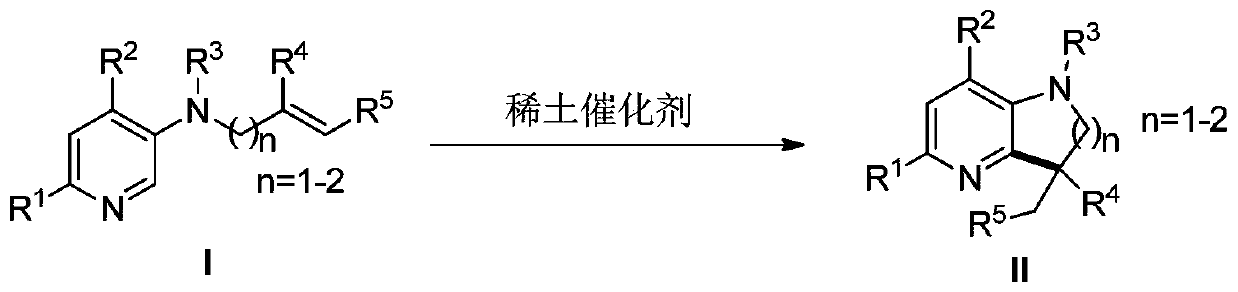

Method for synthesizing azaindoline derivative

A technology of azaindoline and derivatives, which is applied in the field of synthesis of azaindoline derivatives, can solve problems such as poor functional group compatibility, harsh reaction conditions, and poor atom economy, and achieve convenient post-processing, simple catalysts, and synthetic The effect that key efficiency is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation of 1,3-dimethyl-2,3-dihydro-1H-pyrrole[3,2-b]pyridine, the structural formula is as follows:

[0025] Under nitrogen protection, the starting material N-allyl-N-methylpyridin-3-amine (0.5 mmol) and the catalyst Y[N(SiMe 3 ) 2 ] 3 (10 mol%), reacted at 100 ℃ for 24 h to prepare 1,3-dimethyl-2,3-dihydro-1H-pyrrole[3,2-b]pyridine, and the isolated yield of the product was 90%.

[0026] 1 H NMR (CDCl 3 , 500 MHz, ppm): δ 7.75 (d, J = 5.0 Hz, 1H), 6.85 (dd, J = 5.1, 7.8 Hz, 1H), 6.55 (d, J = 7.9 Hz, 1H), 3.52 (t, J = 8.8 Hz, 1H), 3.26-3.22 (m, 1H), 2.82 (t, J = 8.5 Hz, 1H), 2.67 (s, 3H), 1.32 (d, J = 7.0 Hz,3H). 13 C NMR (CDCl 3 , 125 MHz, ppm): δ 156.9, 146.5, 137.8, 121.8, 112.0, 62.1,36.6, 35.6, 17.1.

Embodiment 2

[0028] The preparation of 1,3,5-trimethyl-2,3-dihydro-1H-pyrrole[3,2-b]pyridine, the structural formula is as follows:

[0029] Under nitrogen protection, the starting material N-allyl-N,6-dimethylpyridin-3-amine (0.5 mmol) and the catalyst Y[N(SiMe 3 ) 2 ] 3 (10 mol%), reacted at 100 ℃ for 24 h to prepare 1,3,5-trimethyl-2,3-dihydro-1H-pyrrole[3,2-b]pyridine, and the isolated yield of the product was 81% .

[0030] 1 H NMR (CDCl 3 , 500 MHz, ppm): δ 6.75 (d, J = 7.9 Hz, 1H), 6.54 (d, J =7.9 Hz, 1H), 3.47 (t, J = 8.6 Hz, 1H), 3.26-3.21 (m, 1H), 2.84 (t, J = 8.3Hz, 1H), 2.67 (s, 3H), 2.40 (s, 3H), 1.33 (d, J = 7.0 Hz, 3H). 13 C NMR (CDCl 3 ,125 MHz, ppm): δ 156.6, 146.4, 144.4, 120.8, 113.3, 62.6, 36.9, 36.4, 23.4,17.5.

Embodiment 3

[0032] The preparation of 5-chloro-1,3-dimethyl-2,3-dihydro-1H-pyrrole[3,2-b]pyridine, the structural formula is as follows:

[0033] Under nitrogen protection, the starting materials N-allyl-6-chloro-N-methylpyridin-3-amine (0.5 mmol), dibenzylamine (10 mol%) and catalyst Y were added to toluene (3 mL).[ N(SiMe 3 ) 2 ] 3 (10 mol%), reacted at 100 ℃ for 24 h to prepare 5-chloro-1,3-dimethyl-2,3-dihydro-1H-pyrrole[3,2-b]pyridine, and the isolated yield was 86%.

[0034] 1 H NMR (CDCl 3 , 500 MHz, ppm): δ 6.91 (dd, J = 0.6, 8.2 Hz, 1H), 6.55(d, J = 8.2 Hz, 1H), 3.57 (t, J = 8.9 Hz, 1H), 3.29-3.23 (m, 1H), 2.91 (dd, J = 8.0, 8.7 Hz, 1H), 2.71 (s, 3H), 1.33 (d, J = 6.9 Hz, 3H). 13 C NMR (CDCl 3,125 MHz, ppm):δ 157.4, 145.7, 138.7, 121.7, 114.8, 62.3, 36.6, 35.8, 17.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com