High-temperature-resistant high-density polyethylene geomembrane and preparation method thereof

A high-density polyethylene and geomembrane technology is applied in the field of high-density polyethylene geomembrane to achieve the effects of improving chemical stability, flexibility, tensile properties and stress cracking resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

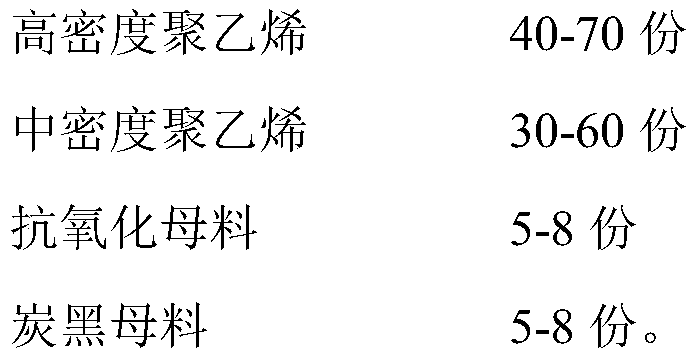

[0035] A high-temperature-resistant high-density polyethylene geomembrane, each raw material component is weighed according to the following proportions by mass:

[0036]

[0037]

[0038] The preparation method is as follows:

[0039] Weigh the above raw materials according to the formula, put them into the mixer and mix for 30 minutes, then send them into the hopper of the three-layer co-extrusion blow molding equipment through the automatic feeder (the temperature setting of each section of the extruder: 185°C, 215°C, 235°C, 235°C, 235°C, 225°C; the connecting body temperature is set to 225°C, the die head temperature is set to 215°C; the length-to-diameter ratio of the extruder screw is 30:1; the die head gap is 3.2mm; the inflation ratio is 1.08; screw speed 52r / min), after the raw materials enter the extruder, they are sheared, melted, plasticized, extruded from the circular die, blown by air, cooled and shaped into a tubular film tube, and then pulled, Cut open a...

Embodiment 2

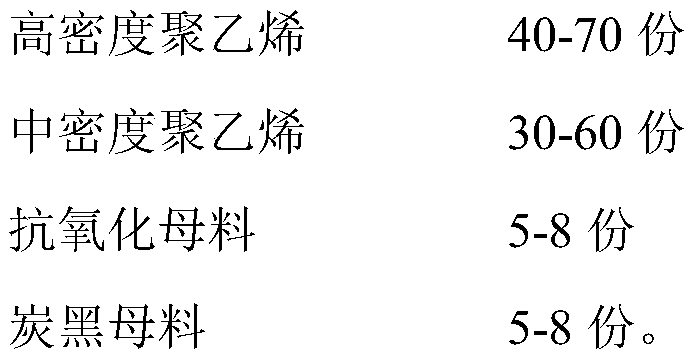

[0041] A high-temperature-resistant high-density polyethylene geomembrane, each raw material component is weighed according to the following proportions by mass:

[0042]

[0043] The preparation method is as follows:

[0044]Weigh the above raw materials according to the formula, put them into the mixer and mix for 30 minutes, then send them into the hopper of the three-layer co-extrusion blow molding equipment through the automatic feeder (the temperature setting of each section of the extruder: 185°C, 215°C, 235°C, 235°C, 235°C, 225°C; the connecting body temperature is set to 225°C, the die head temperature is set to 215°C; the length-to-diameter ratio of the extruder screw is 35:1; the die head gap is 3.2mm; the inflation ratio is 1.06; screw speed 58r / min), after the raw materials enter the extruder, they are sheared, melted, plasticized, extruded from the circular die, blown by air, cooled and shaped into a tubular film tube, and then pulled, Cut open and flatten in...

Embodiment 3

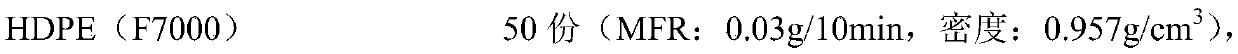

[0046] A high-temperature-resistant high-density polyethylene geomembrane, each raw material component is weighed according to the following proportions by mass:

[0047]

[0048] The preparation method is as follows:

[0049] Weigh the above raw materials according to the formula, put them into the mixer and mix for 30 minutes, then send them into the hopper of the three-layer co-extrusion blow molding equipment through the automatic feeder (the temperature setting of each section of the extruder: 185°C, 215°C, 235°C, 235°C, 235°C, 225°C; the connecting body temperature is set to 225°C, the die head temperature is set to 215°C; the length-to-diameter ratio of the extruder screw is 40:1; the die head gap is 3.2mm; the inflation ratio is 1.02; screw speed 60r / min), after the raw materials enter the extruder, they are sheared, melted, plasticized, extruded from the circular die, blown by air, cooled and shaped into a tubular film tube, and then pulled, Cut open and flatten i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com