A method to reduce the supercooling degree of water

A supercooling, pure water technology, applied in chemical instruments and methods, heat exchange materials, applications, etc., can solve the problems of reducing water subcooling, increasing energy consumption of ice machines, etc., to eliminate subcooling, The effect of reducing energy consumption and shortening the freezing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

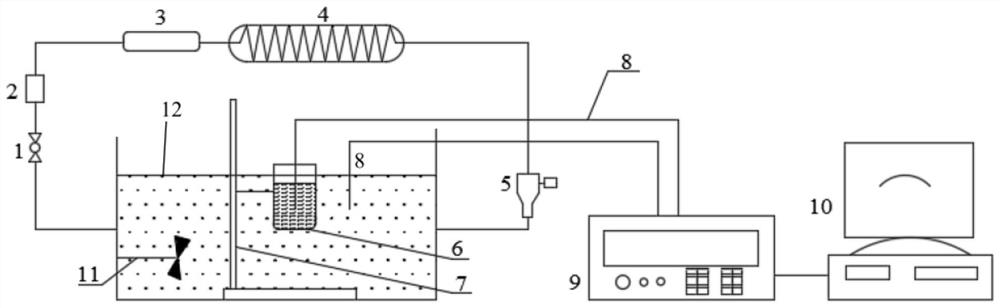

Method used

Image

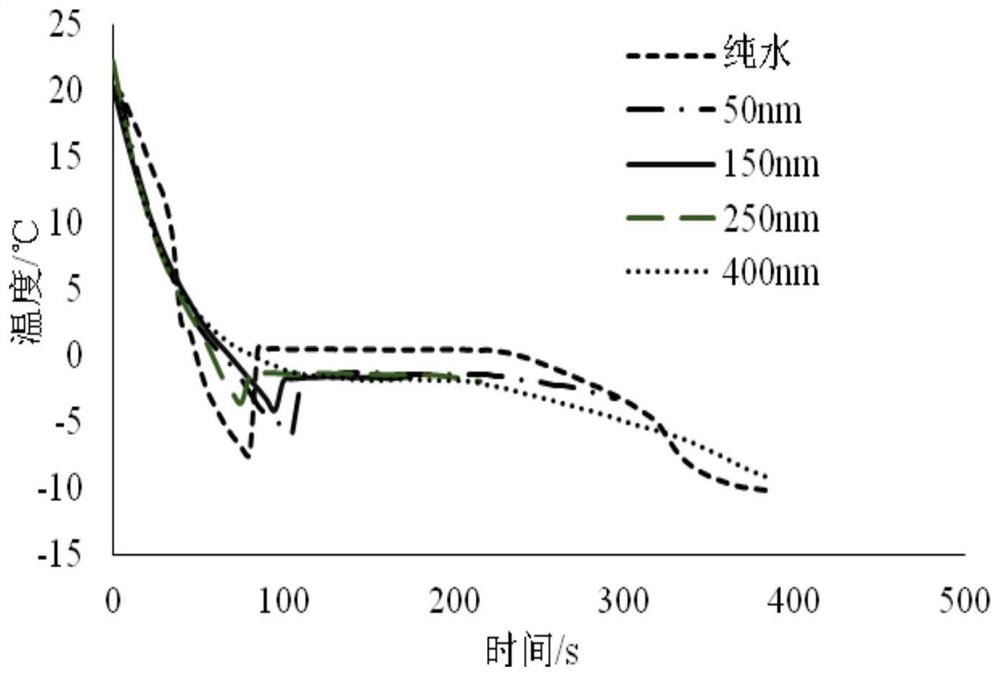

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described below through specific embodiments and accompanying drawings. Unless otherwise specified, the raw materials used in the examples of the present invention are commonly used raw materials in the art, and the methods used in the examples are conventional methods in the art.

[0029] The term "fluidized ice" in the present invention refers to a solid-liquid two-phase solution containing suspended ice crystal particles, wherein the ice crystal particles are tiny, with a diameter of no more than 1 mm, strong fluidity, and can be transported by pumps.

[0030] The term "water subcooling" in the present invention refers to the difference between the actual freezing temperature of water and the theoretical freezing temperature.

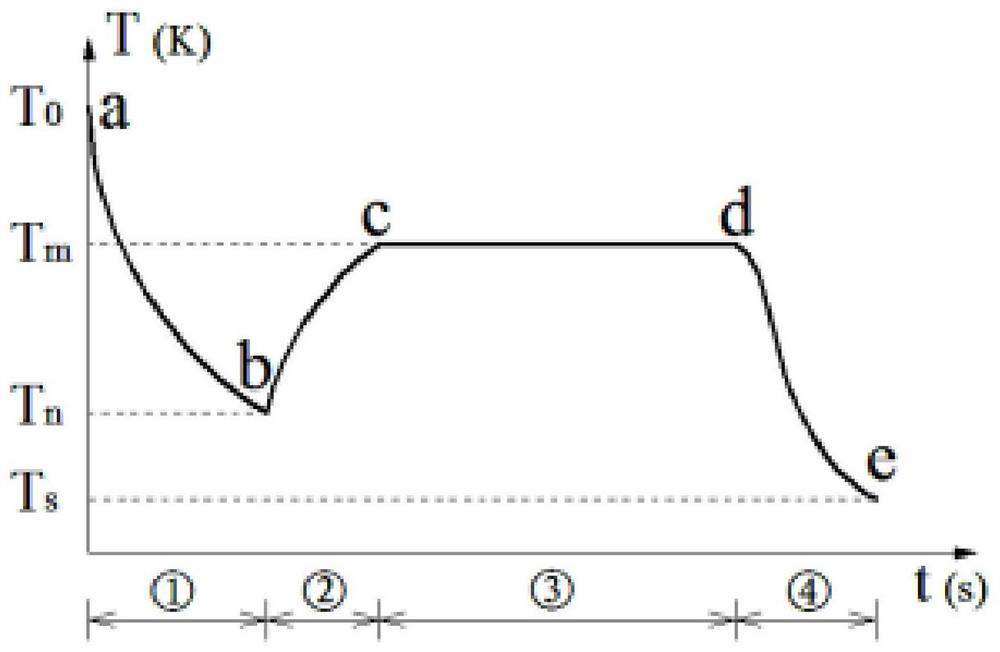

[0031] Water, including tap water, pure water, mineral water or sea water, can be divided into four stages theoretically when it cools down to form ice crystals, such as figure 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com