A system and method for in-situ leaching and stratified liquid collection of thick weathering crust leaching type rare earth ore

A weathering crust leaching type, in-situ leaching technology, applied in the direction of improving process efficiency, can solve problems such as affecting the recovery rate of rare earth, geological disasters, loss of leachate, etc., to achieve sustainable and efficient production, improve the recovery rate of rare earth, reduce The effect of leachate loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

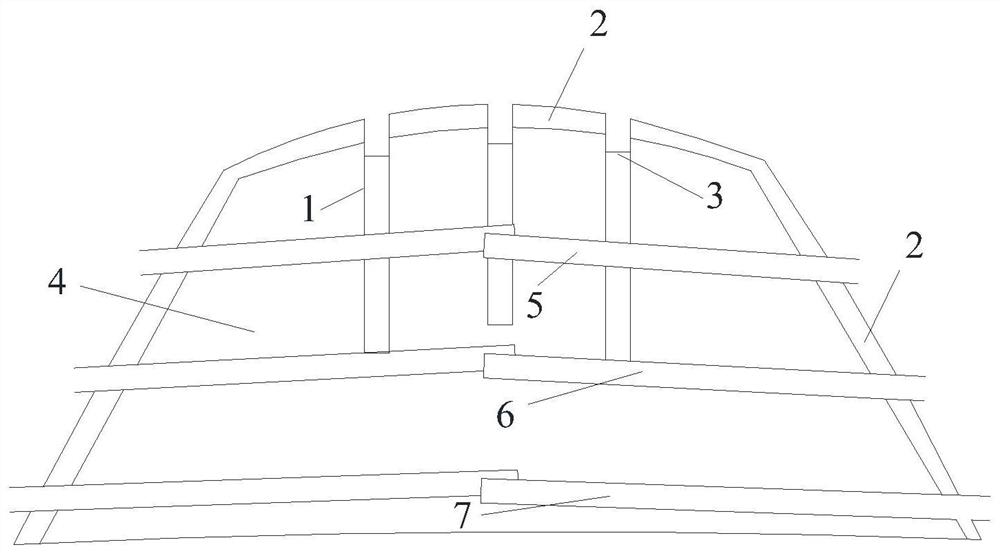

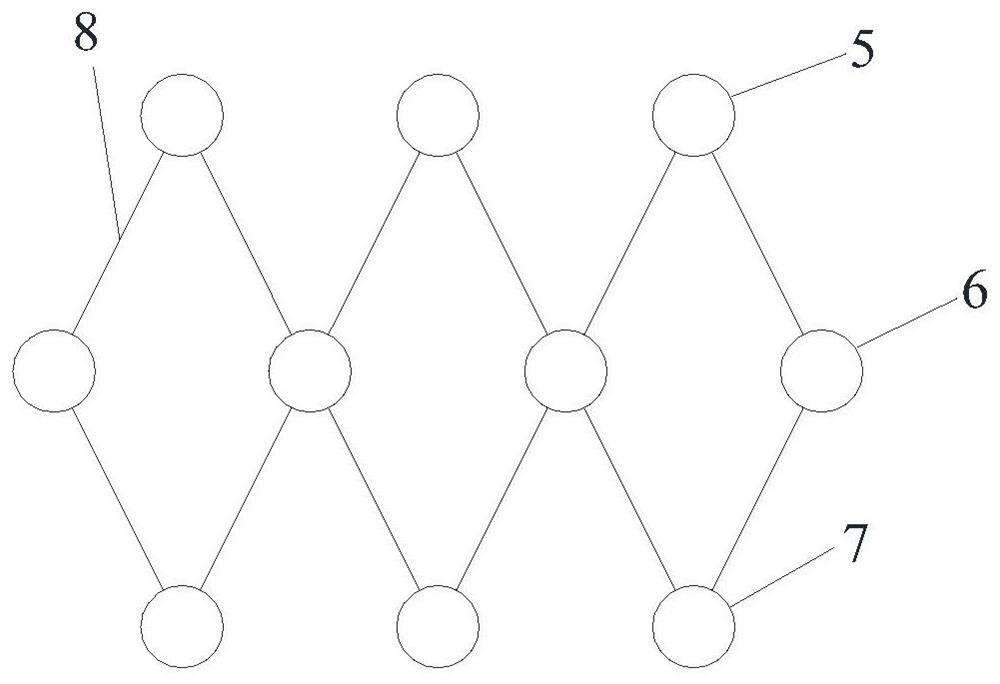

[0032] Such as Figure 1-2 As shown, this embodiment provides a thick weathering crust leaching type rare earth ore in-situ leaching layered liquid collection system. The ore body 4 consists of humic layer 2, fully weathered layer and semi-weathered layer from top to bottom. The in-situ leaching layered liquid collection system for thick weathering crust leaching type rare earth ore includes 1 / 3 of the thickness of the ore body 4, 2 / 3 of the thickness and 5 to 15 cm below the interface between the semi-weathered layer and the bedrock along the ore body. 4. One layer of liquid collection and diversion hole groups arranged separately, one-to-one corresponding liquid collection grooves and liquid collection pools arranged in the valley, each layer of liquid collection and diversion hole groups include A plurality of liquid collection diversion holes arranged in parallel and at intervals, the liquid collection diversion holes of the three-layer liquid collection diversion hole gro...

Embodiment 2

[0039] A high-altitude thick weathering crust leaching type rare earth ore in southern Yunnan, the rare earth composition is medium yttrium rich in europium, and the average grade of rare earth is RE 2 o 3 0.079%. The mine adopts the in-situ leaching layered liquid collection method to recover rare earths, and the specific steps are as follows:

[0040] S1. Arrange grid injection wells 1 along the surface of the ore body 4, with a spacing of 2×2m. The diameter of the injection wells 1 is 10cm, and the depth reaches the semi-weathered layer. Equivalent, and a high-strength PVC pipe with a diameter of 4 cm allows all the leaching solution 2% ammonium sulfate to quickly flow into the ore body 4 through the PVC pipe, effectively preventing hole collapse, controlling the flow of the leaching agent, and making the leaching agent solution The liquid level 3 in the liquid well 1 is lower than the humus layer 2;

[0041] S2. Using a thousand-meter drill, drill a row of parallel liqu...

Embodiment 3

[0046] A high-altitude thick weathering crust leaching type rare earth ore in southern Yunnan, the rare earth composition is medium yttrium rich in europium, and the average grade of rare earth is RE 2 o 3 0.091%. The mine adopts the in-situ leaching layered liquid collection method to recover rare earths, and the specific steps are as follows:

[0047] S1. Arrange grid injection wells 1 along the surface of the ore body 4 with a spacing of 3×3m. The diameter of the injection wells 1 is 15cm, and the depth reaches the semi-weathered layer. Equivalent, and a high-strength PVC pipe with a diameter of 6 cm allows all the leaching solution 2% ammonium sulfate to quickly flow into the ore body 4 through the PVC pipe, effectively preventing hole collapse, controlling the flow of the leaching agent, and making the leaching agent solution The liquid level 3 in the liquid well 1 is lower than the humus layer 2;

[0048] S2. Using a thousand-meter drill, drill a row of parallel liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com