Support pre-stress connection joint of concrete support frame structure

A technology for supporting frames and connecting nodes, which is applied in the direction of building structure, construction, etc., can solve the problems of affecting the quality of concrete pouring, unclear force transmission in node areas, and difficult construction, so as to save costs, construction processes and procedures Simple, easy-to-make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

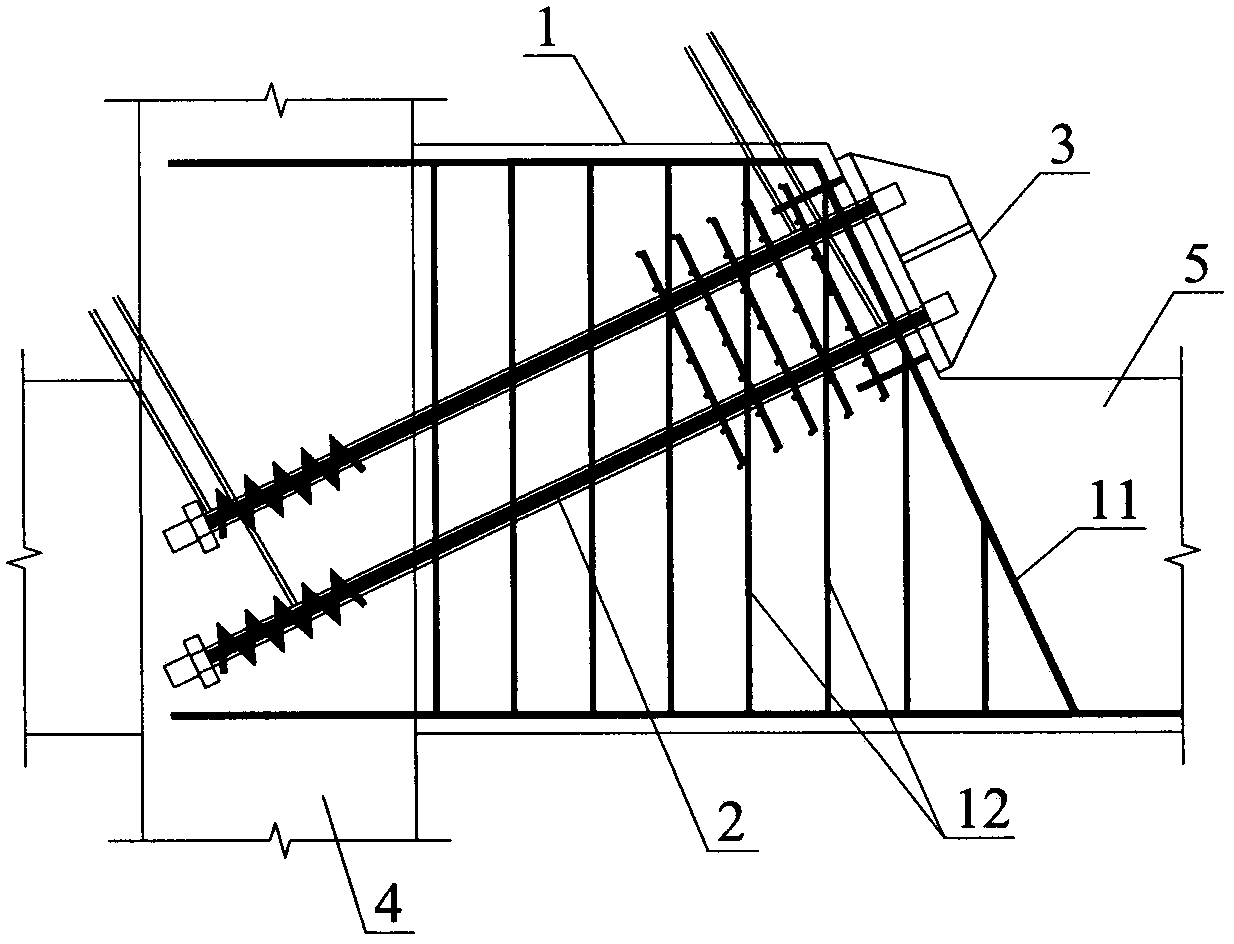

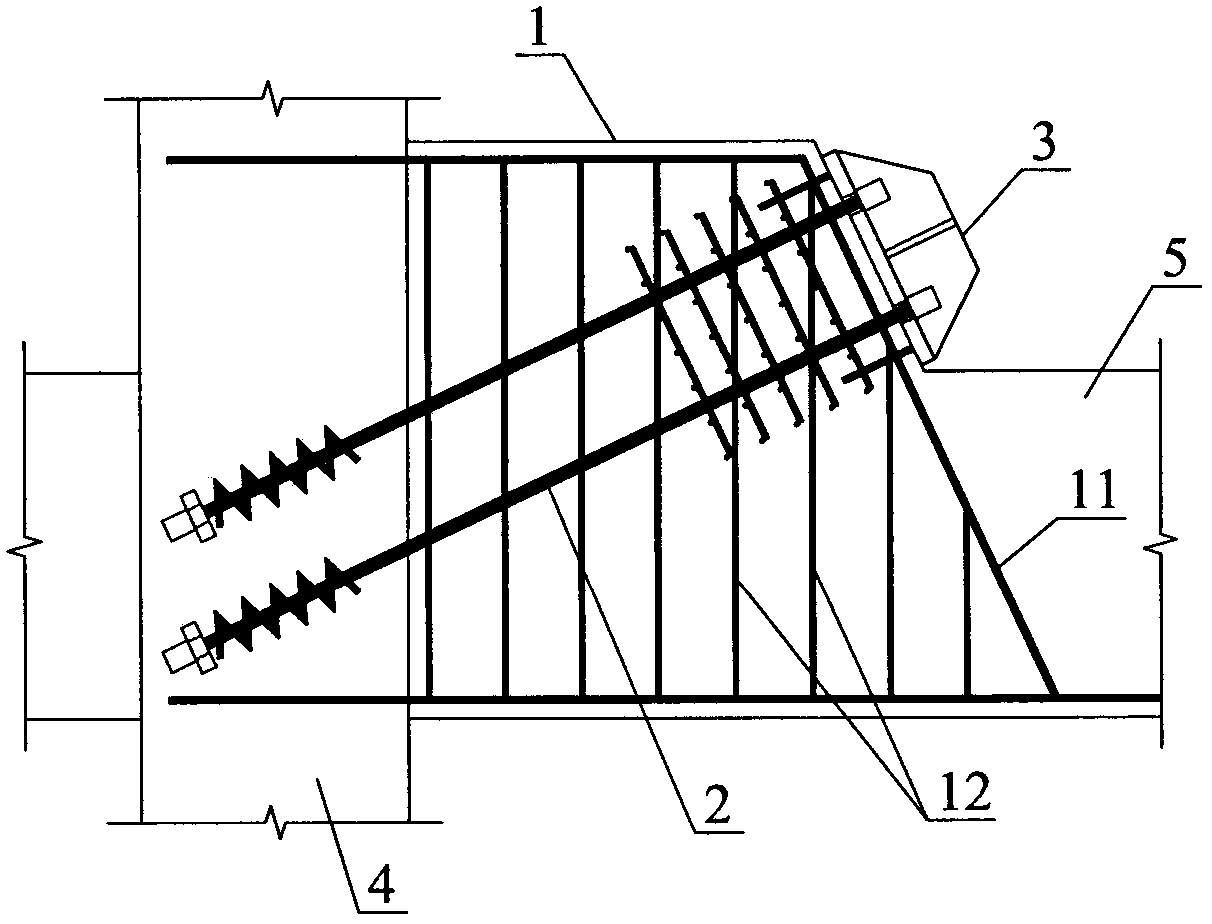

[0019] see Figure 1-6 , a support prestressed connection node of a concrete support frame structure of the present invention, comprising a concrete abutment 1 in the node area, a prestressed component 2, and a pre-embedded connector 3 .

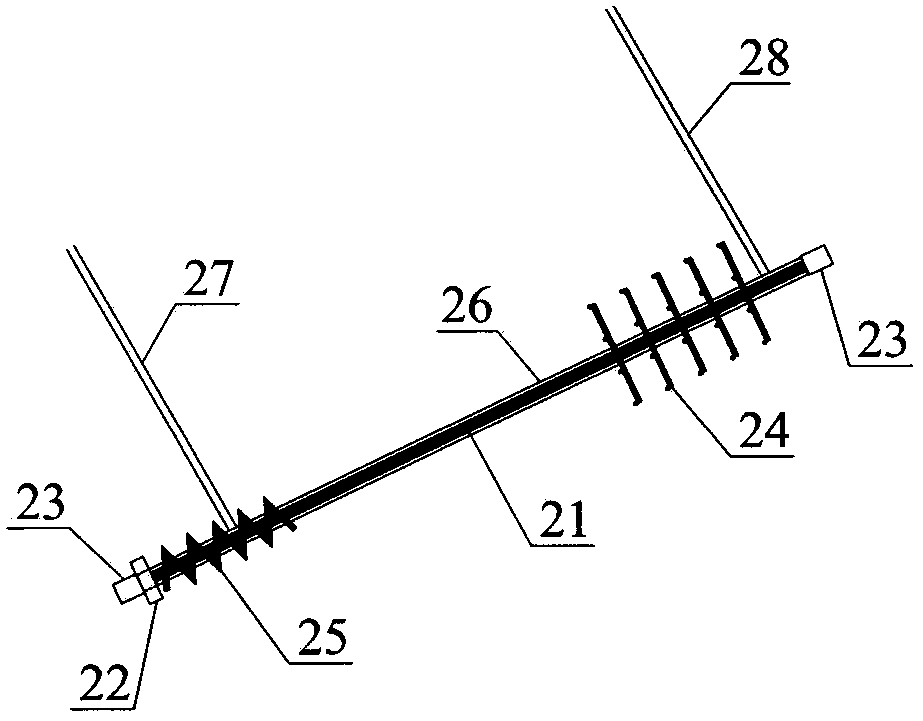

[0020] Set vertical bars 11 in the concrete abutment 1, and insert them into the structural columns 4 and structural beams 5 to meet certain anchorage length requirements, and the stirrups 12 are bound between the vertical bars 11 and the longitudinal bars of the structural beams 5; The prestressed component 2 includes high-strength prestressed steel bars 21, inner anchor plates 22, anchors 23 at both ends of the prestressed steel bars, grid-type indirect steel bars 24 or spiral-type indirect steel bars 25; the embedded connector 3 includes embedded steel plates 31. Connecting steel plates 32 and anchor bars 33, the pre-embedded steel plates 31 are pre-embedded on the surface of the concrete abutment 1, the connecting steel plates 32 are wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com