Concrete flexural member with prestressed aluminum alloy plate and its flexural strengthening method

A technology of aluminum alloy plates and bending components, which is applied in building structures, truss structures, joists, etc., can solve problems such as super-reinforcement damage, and achieve the effects of avoiding stress concentration and interface peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present application will be described in detail below in conjunction with the accompanying drawings and specific examples. This example is implemented on the premise of the technical solution of the present application, and provides detailed implementation and specific operation process, but the protection scope of the application is not limited to the following implementation operation process.

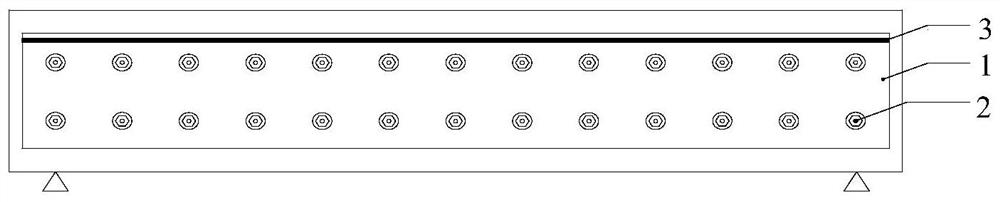

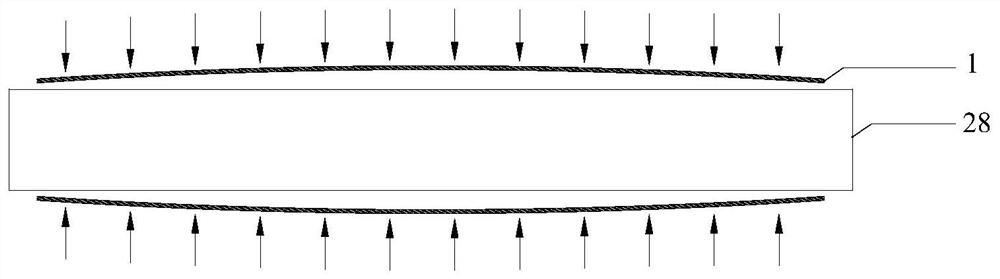

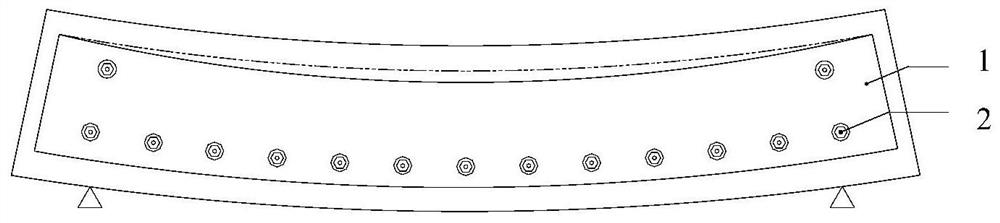

[0043] This application can be widely used in the reinforcement and transformation of structures such as buildings and bridges, as well as post-disaster repairs such as earthquakes and fires. The aluminum alloy plate 1 on the side of the beam is connected and fixed to the main body 28 of the concrete bending member by using the post-anchoring technology of planting bars. The rib-type post-anchoring technology ensures the joint work of the aluminum alloy plate 1 on the beam side and the main body 28 of the concrete bending member. The aluminum alloy plate 1 on the beam side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com