Contour error controller for multi-axis motion system and control method thereof

A multi-axis motion and contour error technology, applied in digital control, program control, computer control, etc., can solve the problem of affecting the position accuracy and contour accuracy of the CNC machining system, increasing the complexity of the cross-coupling controller, and being easily affected by external disturbances To achieve the effect of ensuring single-axis tracking accuracy and robustness, ensuring contour control accuracy, improving dynamic performance and parameter matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

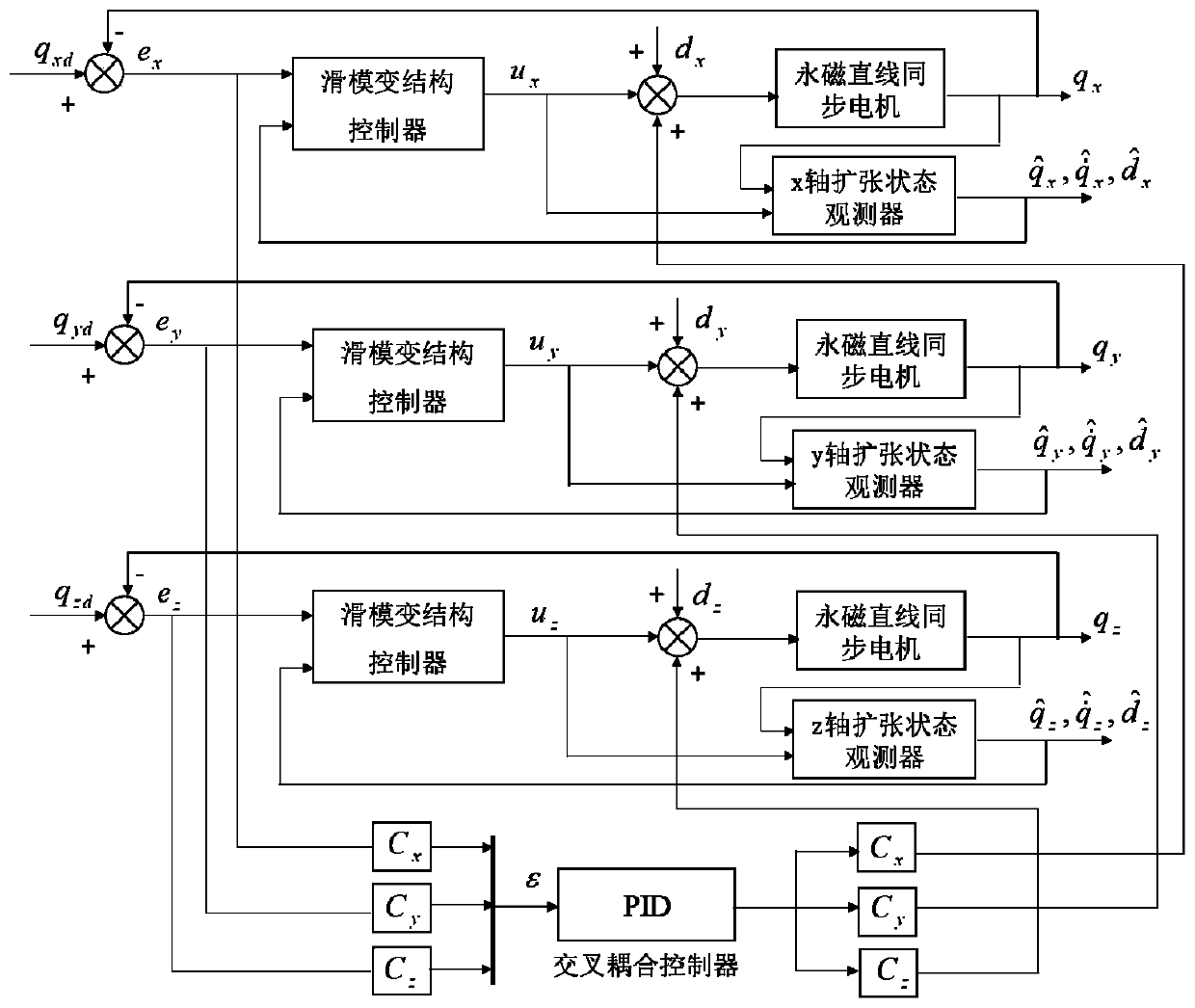

[0051] In the prior art, the mismatch of the dynamic characteristics of the motors of each axis is the main cause of the contour error. In this embodiment, the cross-coupling control is used to coordinate the movements between the axes, and the appropriate cross-coupling control gain is selected to calculate the contour error and calculate the contour error. Allocate the contour error compensation amount for each axis to each axis. Therefore, it is very important to establish a more accurate contour error model. This embodiment proposes an effective two-axis contour error vector estimation method for non-circular arbitrary contours, and further calculates a multi-axis contour error calculation formula.

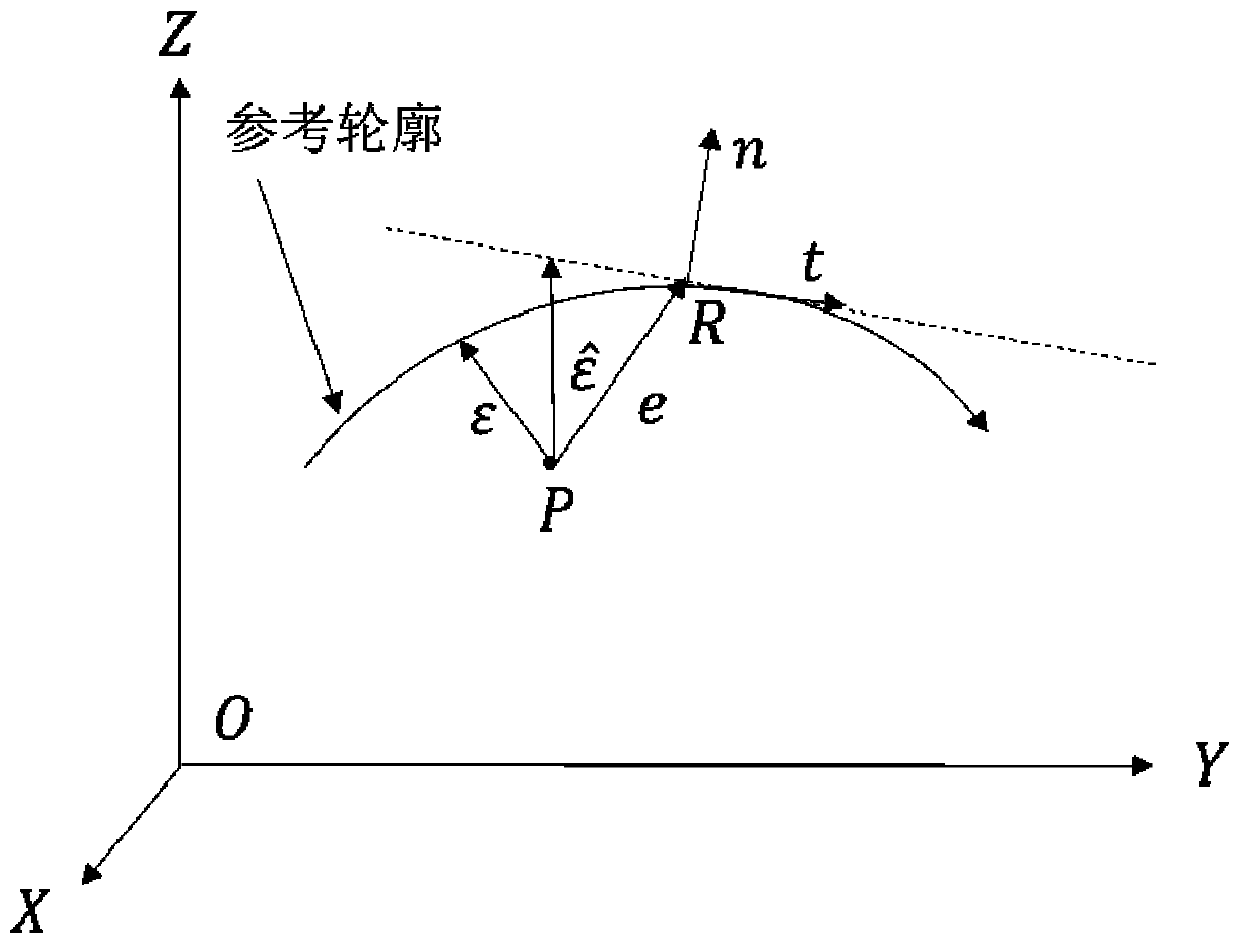

[0052] The three-dimensional space motion contour error vector diagram is as follows figure 1 where P is the actual position, R is the reference position, e is the tracking error vector between the reference position and the actual position, t is the normalized tangent vector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com