Clamp ring spraying manipulator device and method

A manipulator, pincer-shaped technology, applied in manipulators, injection devices, manufacturing tools, etc., can solve problems such as difficulty in operation, and achieve the effects of reducing energy consumption, wide range and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

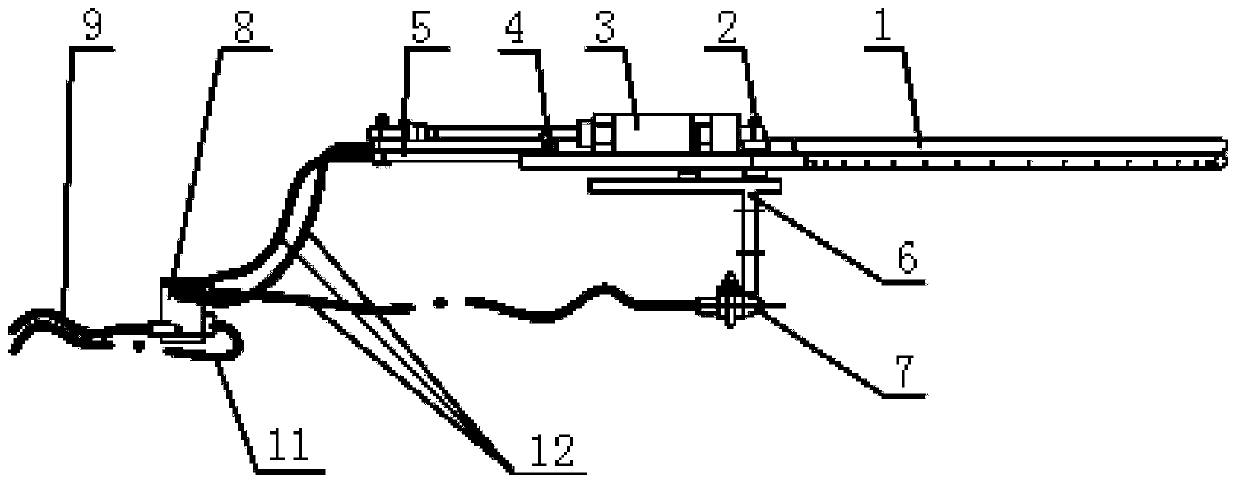

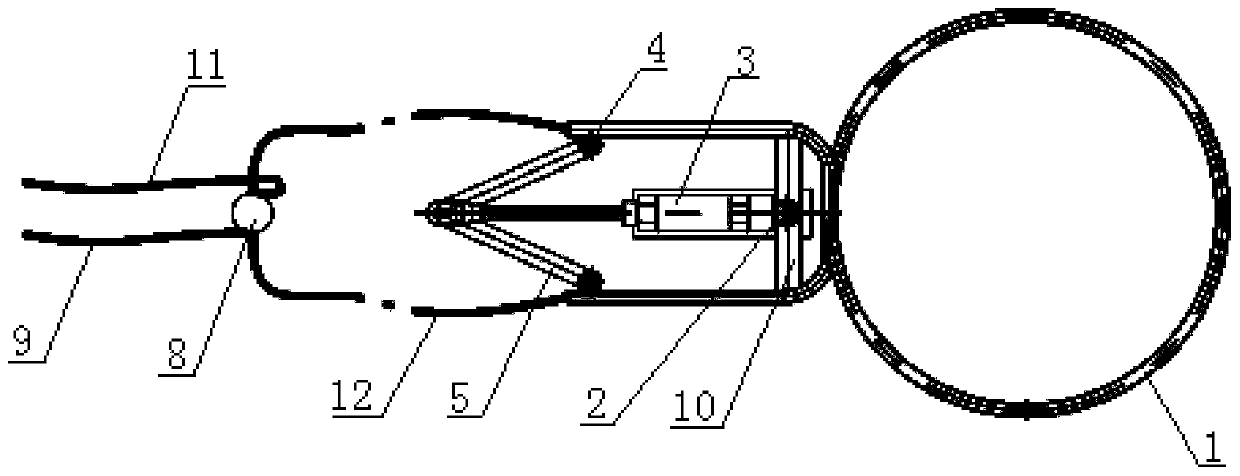

[0027] figure 1 Schematically shows a schematic view of the structure of the pincer ring spray manipulator device according to the present invention, figure 2 Schematically shows the top view of the pincer ring spray manipulator device according to the present invention, as figure 1 and 2 As shown, a pincer ring spray manipulator device includes two symmetrical pincer ring assemblies 1, a connecting shaft 2, a pincer ring assembly driving mechanism 3, a connecting sleeve 4, a connecting rod 5, and a connecting flange bracket 6. Large fan angle direct jet rotary nozzle 7. Gas-liquid two-phase flow mixer 8.

[0028] Wherein, the tails of the two pincer ring assemblies 1 are connected with the output rods of the pincer ring assembly driving mechanism 3 through two connecting rods 5, and the linear reciprocating motion of the pincer ring assembly driving mechanism 3 is made through the connecting rods 5. The pincer ring assembly 1 is extended or closed, and the tail of the con...

Embodiment 2

[0043] In this embodiment, the driving mechanism 3 of the clamp ring assembly also includes an electric push rod connected to an external power supply through a cable. As this embodiment, the pincer ring assembly 1 can be driven by an electric push rod, and other structures of the device are the same as those of embodiment 1, so details are not repeated here.

[0044] Figure 5 Shown schematically according to the present invention adopts electric push rod as the pincer ring spraying method of driving force, as Figure 5 As shown, according to another aspect of the present invention, a kind of pincer ring spraying method is provided, comprising the steps:

[0045] Step S201: Adjust the retraction stroke of the electric push rod according to the diameter of the cylindrical product to be processed, and the pincer ring assembly 1 drives the connecting rod 5 to the open position through the electric push rod, which is beneficial to embrace the cylindrical product;

[0046] Step ...

Embodiment 3

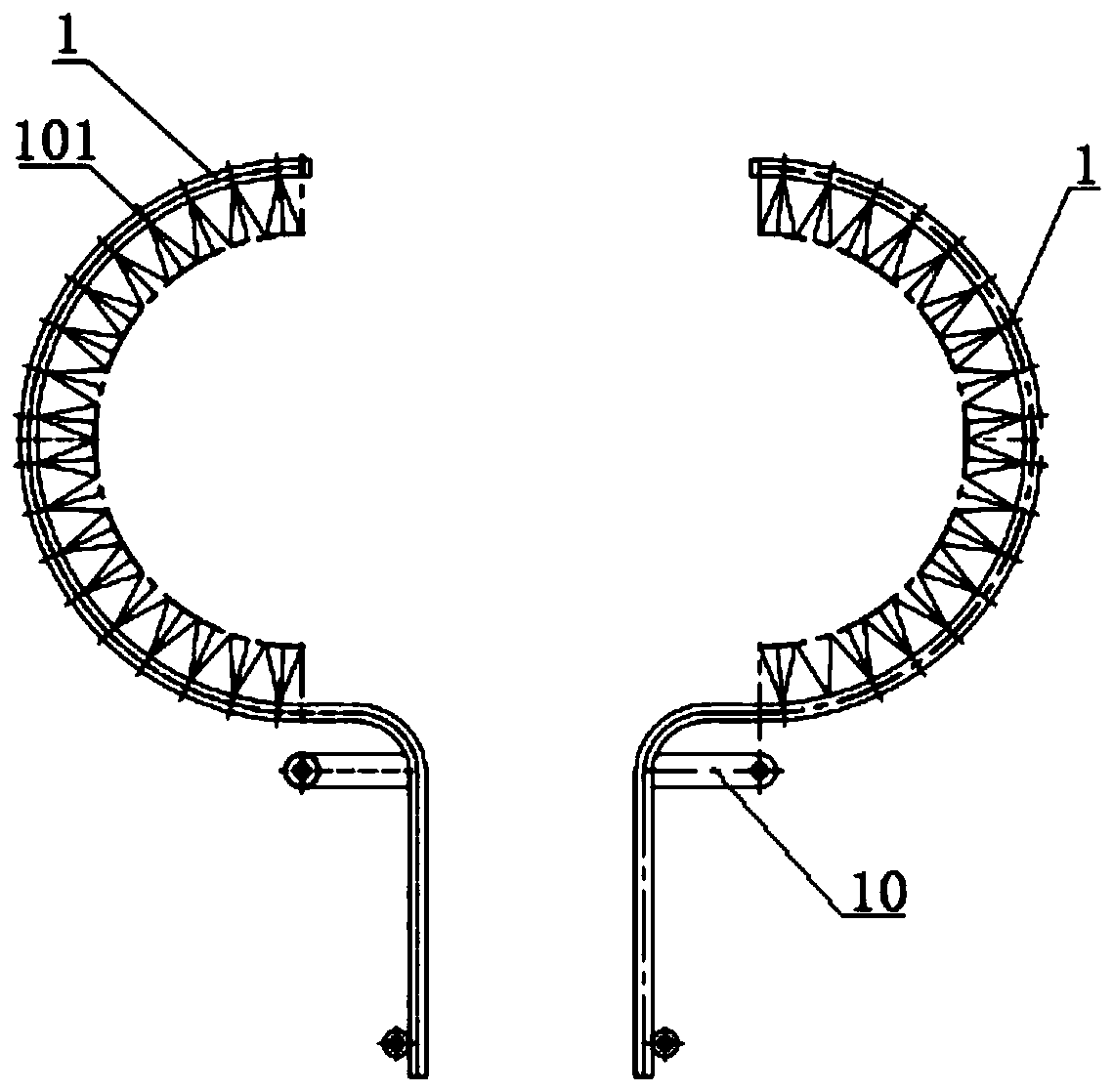

[0051] Image 6 Schematically shows the schematic diagram of the pincer ring spray manipulator device according to the present invention according to the operation of a product shape, such as Image 6 As shown, this embodiment is applied to a cylindrical product with a larger diameter. At this time, to put the cylindrical product into the clamp ring assembly 1, the clamp ring assembly 1 needs to be opened to a large extent, so that the Put the cylindrical product into the clamp ring assembly 1, then at this time, the driving mechanism 3 of the clamp ring assembly is adjusted to a medium stroke according to the cylindrical product, and the clamp ring assembly 1 is opened in a wide range through the connecting rod. The cylindrical product is put into the pincer ring assembly 1 and then tightened. Finally, the injection port 101 of the pincer ring assembly 1 and the large fan angle direct-fire rotary nozzle 7 perform 360°circling and up and down processing on it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com