A metal plate bending auxiliary equipment and using method thereof

A technology of sheet metal and auxiliary equipment, applied to metal processing equipment, cleaning methods using tools, cleaning methods, and appliances, can solve problems such as high labor intensity, large loss of bending force, and poor bending characteristics of sheet metal, achieving Improve bending quality, reduce friction loss, and reduce the effect of external force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

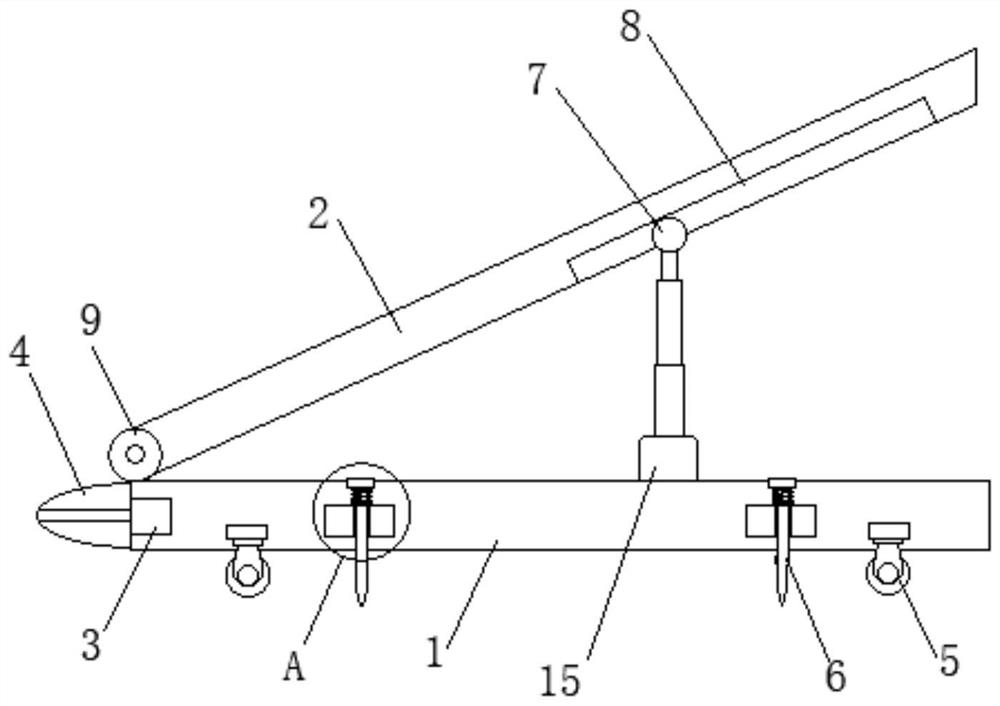

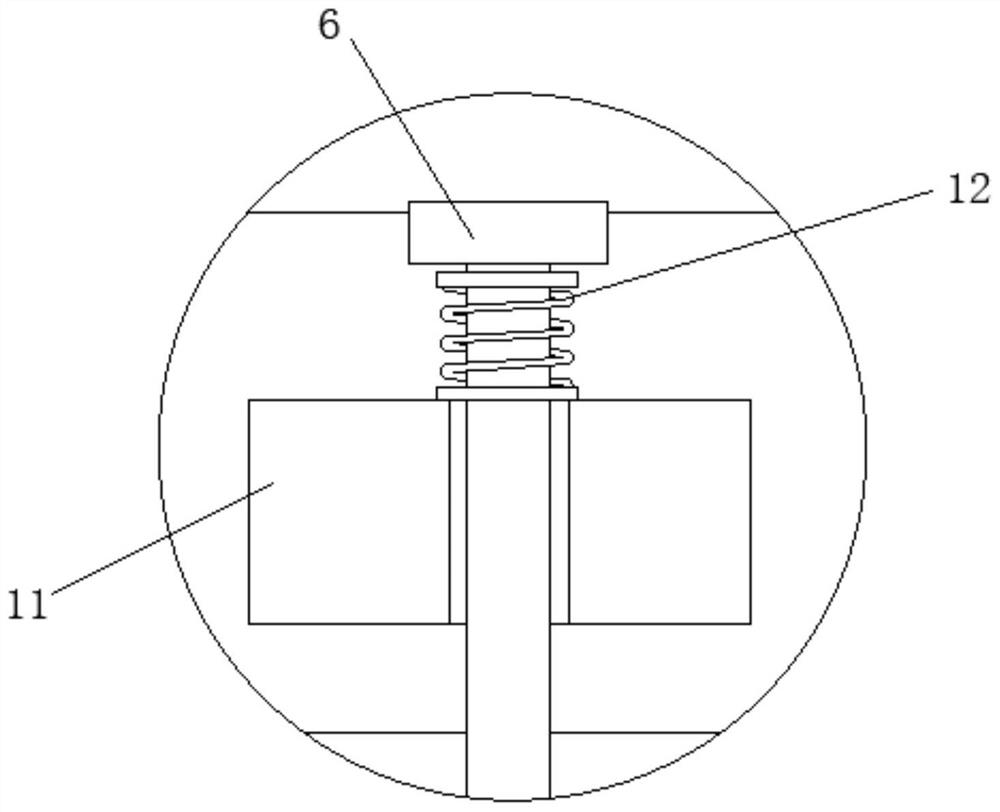

[0046] see figure 1 , a metal plate bending auxiliary equipment, including a mobile base 1, the upper side of the mobile base 1 is provided with a contrast adjustment plate 2, please refer to figure 2 , a rotating shaft 9 is connected between the front end of the mobile base 1 and the end of the contrast adjustment plate 2, please refer to Figure 4 , the rotating shaft 9 is provided with a fan-shaped angle ruler 10, and the lower end of the fan-shaped angle ruler 10 is fixedly connected with the mobile base 1, and the operator can adjust the angle between the contrast adjustment plate 2 and the mobile base 1 according to the scale on the fan-shaped angle ruler 10, and move The middle part of the upper end of the base 1 is fixedly connected with a hydraulic cylinder 15, which is used to drive the rotation of the control adjustment plate 2. The side end of the mobile base 1 is connected with a universal wheel 5 and a positioning mechanism. The universal wheel 5 facilitates the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com