Cutting machine and cutter cooling device thereof as well as cutter main cooling spray head

A technology for cooling nozzles and cooling devices, which is applied to fine working devices, manufacturing tools, working accessories, etc., can solve the problems that the main cooling nozzles of tools cannot be applied and the scope of application is narrow, so as to improve the cutting effect, prolong the service life, and overall compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

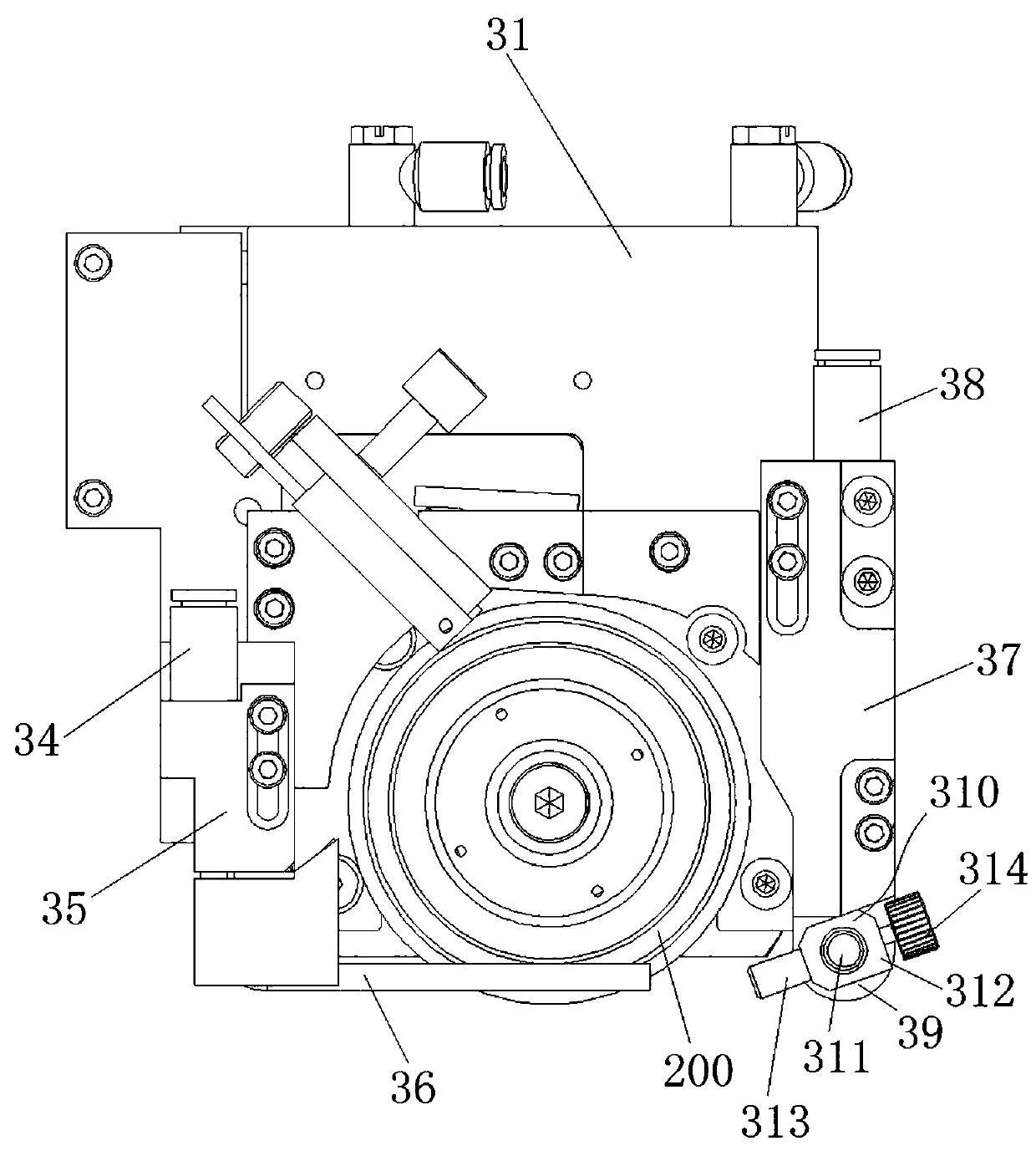

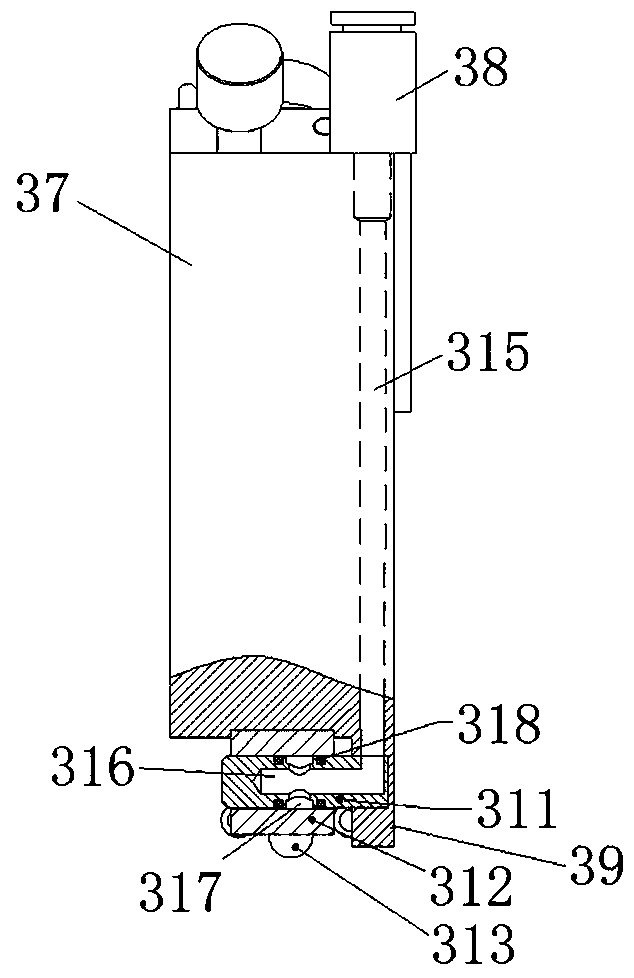

[0064] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

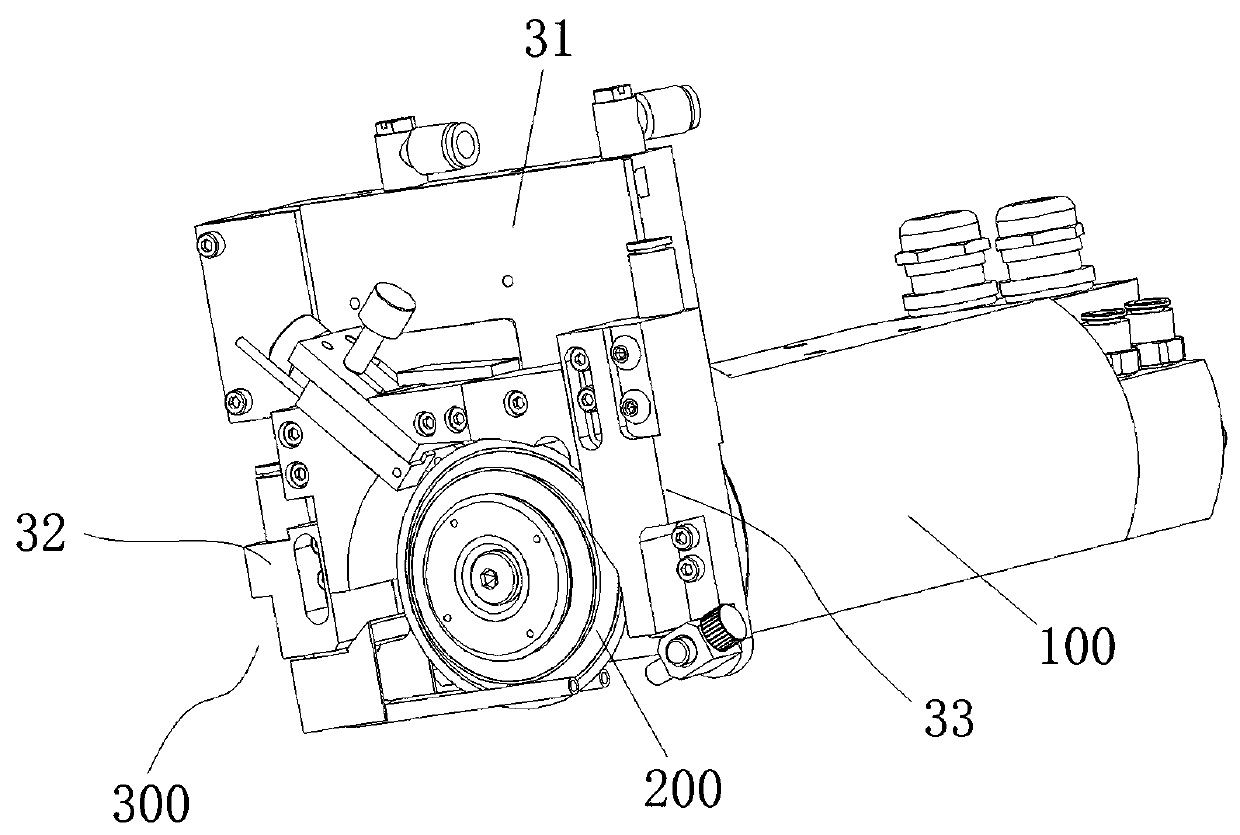

[0065] Specific embodiment 1 of the dicing machine of the present invention, such as Figure 1 to Figure 3 As shown, the dicing machine includes a frame, and a worktable is fixed on the frame. When in use, the workpiece is positioned on the workbench and the workpiece is firmly fixed by vacuum adsorption. The workbench can reciprocate along the X-axis direction move. A mobile frame is also installed on the frame, and the air static pressure high-speed spindle 100 is fixedly installed on the mobile frame. A blade 200 is installed at one end of the air static pressure high-speed spindle 100. The mobile frame can move relative to the workbench to drive the air static pressure high-speed spindle. 100 and the blade 200 move to slice and cut the workpiece to be processed.

[0066] In order to cool the blade 200 when the blade 200 is cutting, and take away th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com