A pouring heat-insulating aluminum profile

A technology of casting aluminum profiles, which is applied in construction, building components, building structures, etc., can solve the problems of high production cost of pouring heat-insulating aluminum profiles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

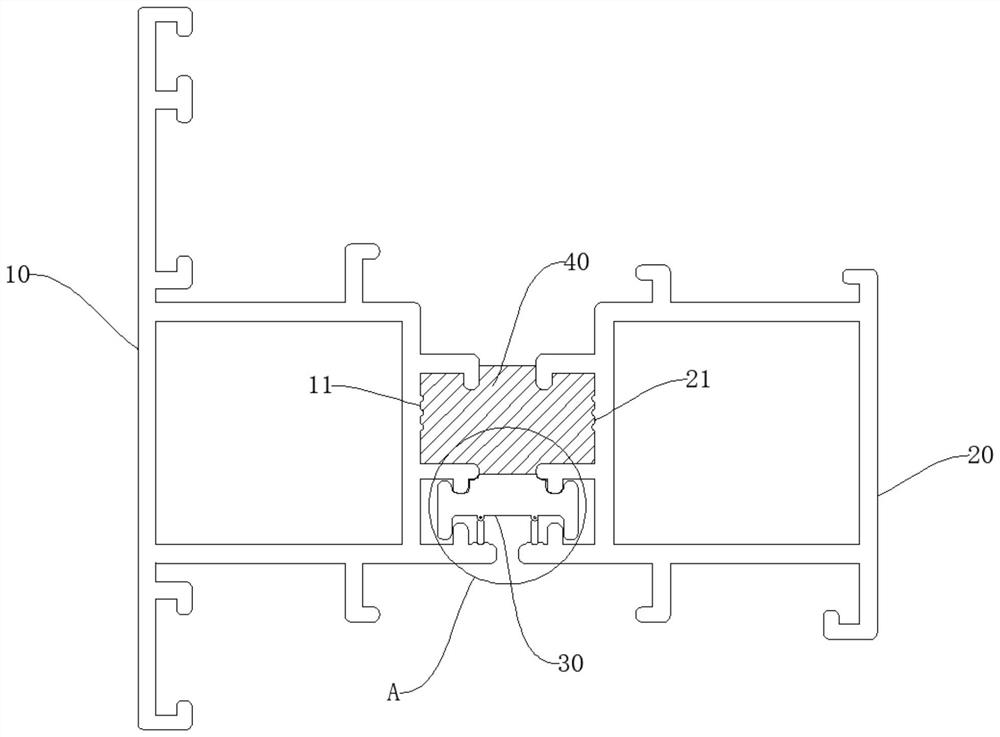

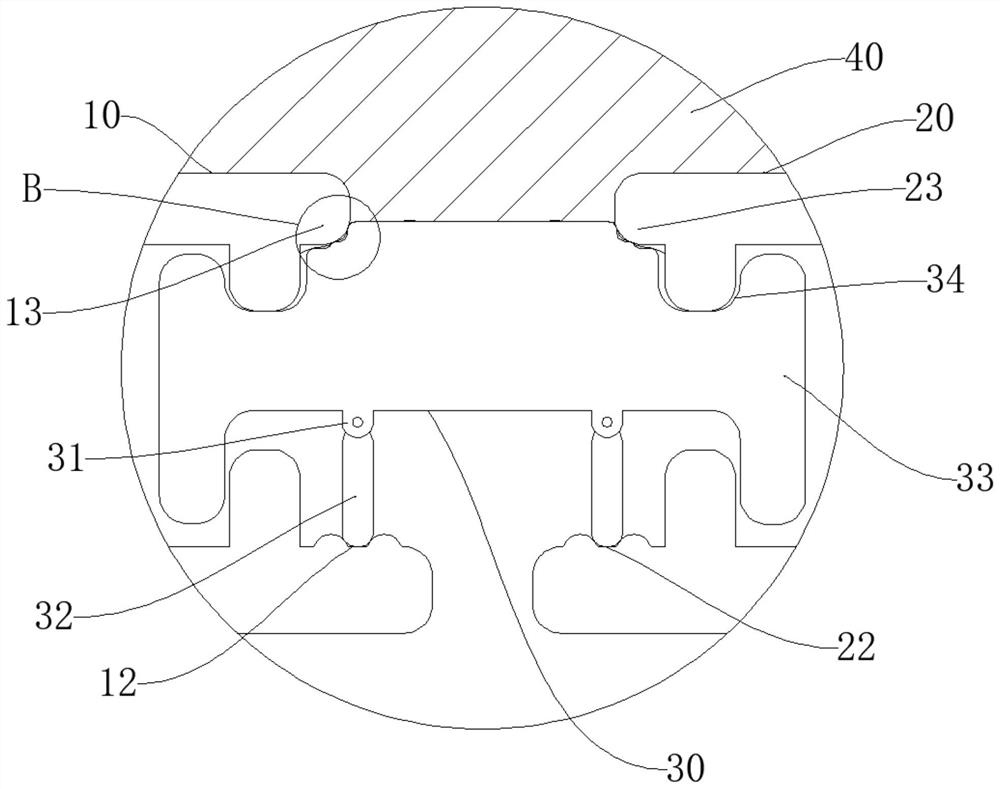

[0026] see Figure 1-5 , an embodiment provided by the present invention: a castable heat-insulating aluminum profile, including aluminum profile one 10, aluminum profile two 20 and glue injection 40, wherein the material of glue injection 40 can be PA66, that is, polyadipyl adipyl Diamine resin also includes bridging support 30 and refractory film 50 , wherein the material of bridging support 30 can be aluminum alloy or steel with higher mechanical strength to meet the requirement of long-term repeated use.

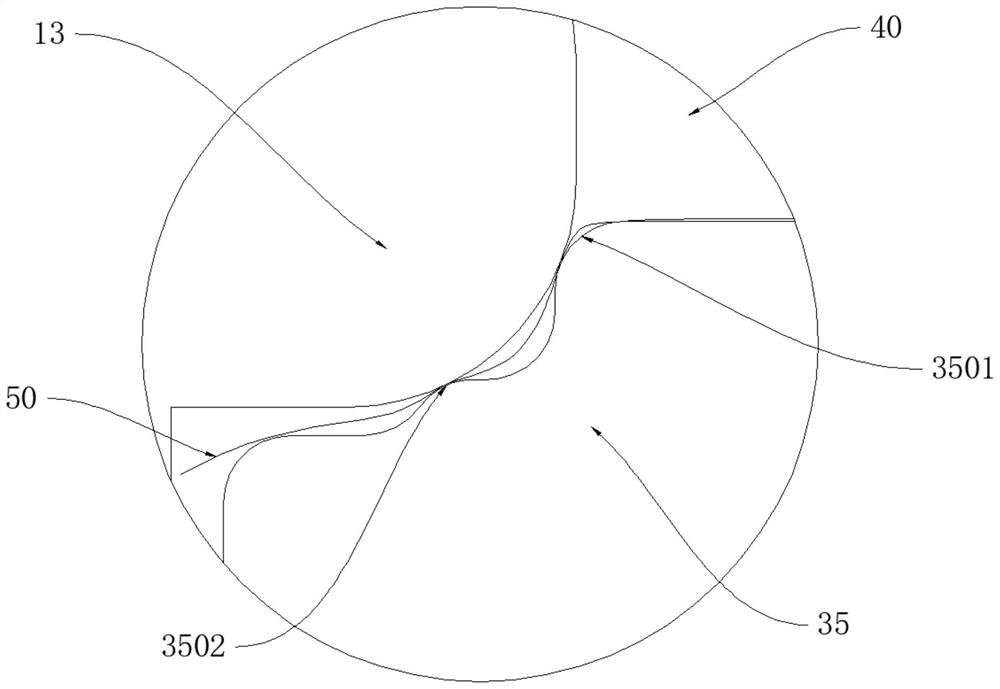

[0027] Further, the material of the refractory film 50 can be selected from aluminum foil, polytetrafluoroethylene, polyphenylene sulfide, polyether ether keto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com