Automatic control method for hazardous waste incineration

A hazardous waste and algorithm technology, applied in combustion methods, neural learning methods, incinerators, etc., can solve problems such as low production efficiency, impact on enterprise production, delay in operating conditions, etc., to improve stability and start-up rate, and realize Fully automatic control, reducing the effect of experience dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

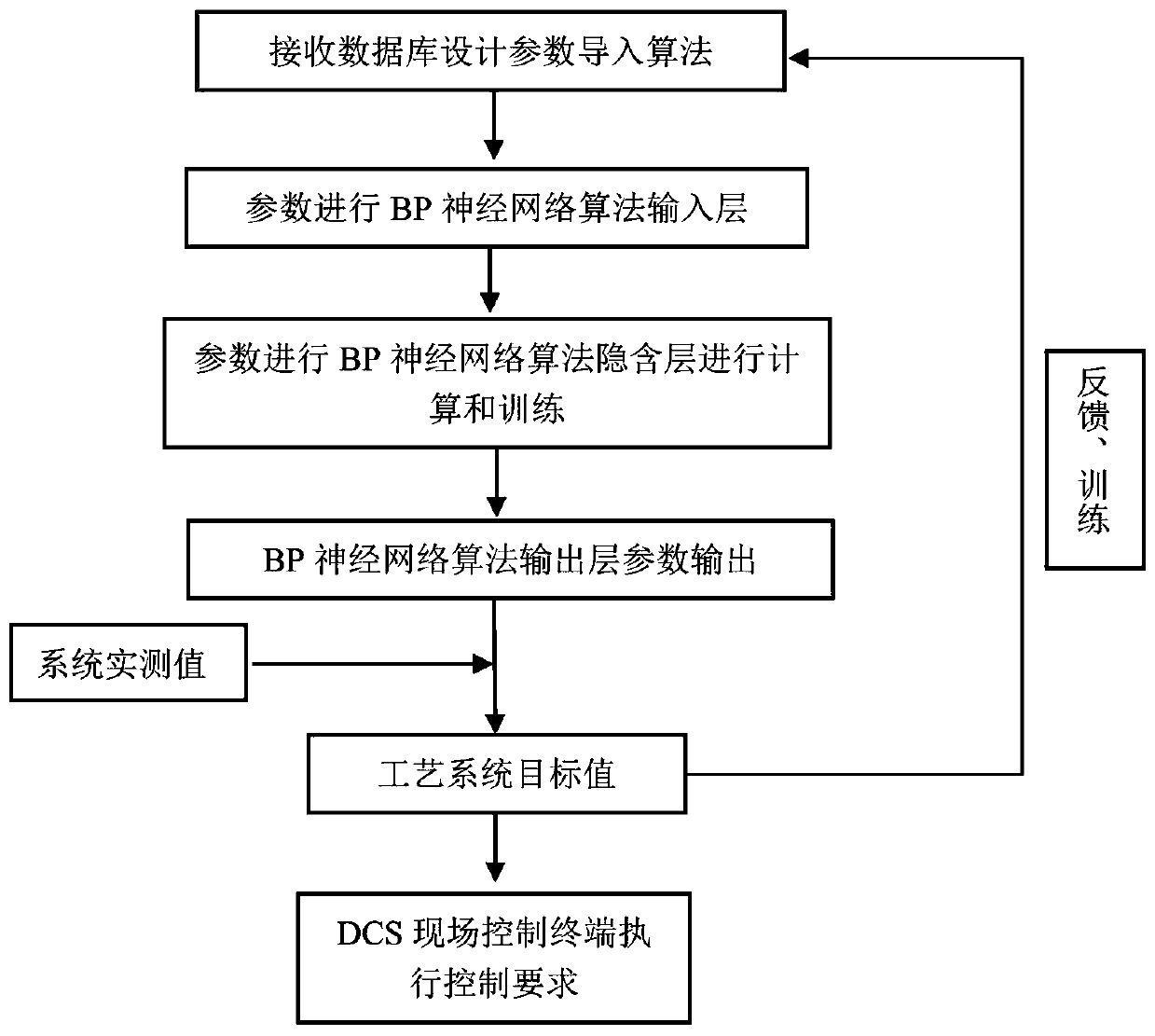

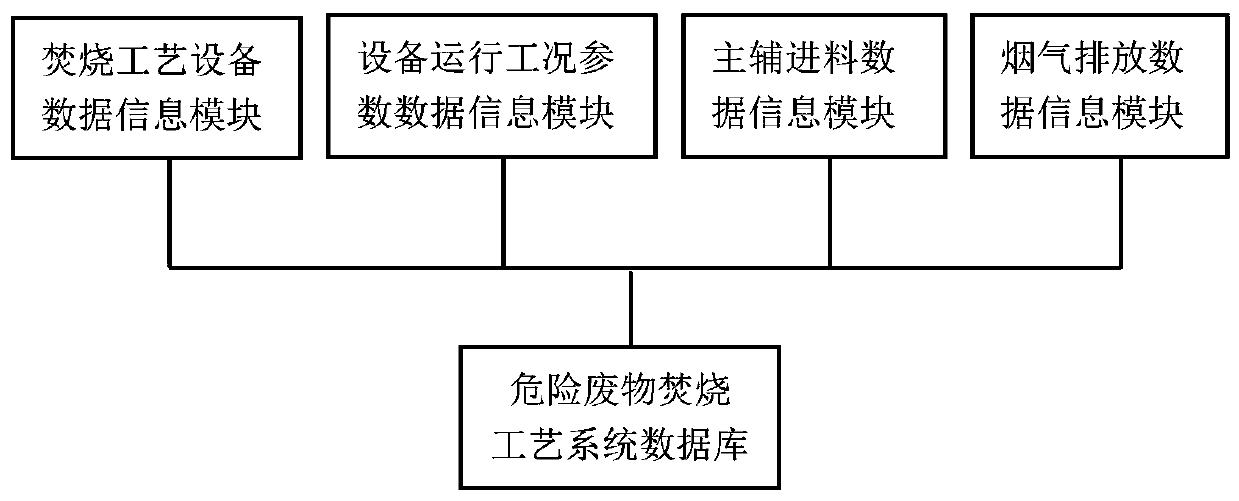

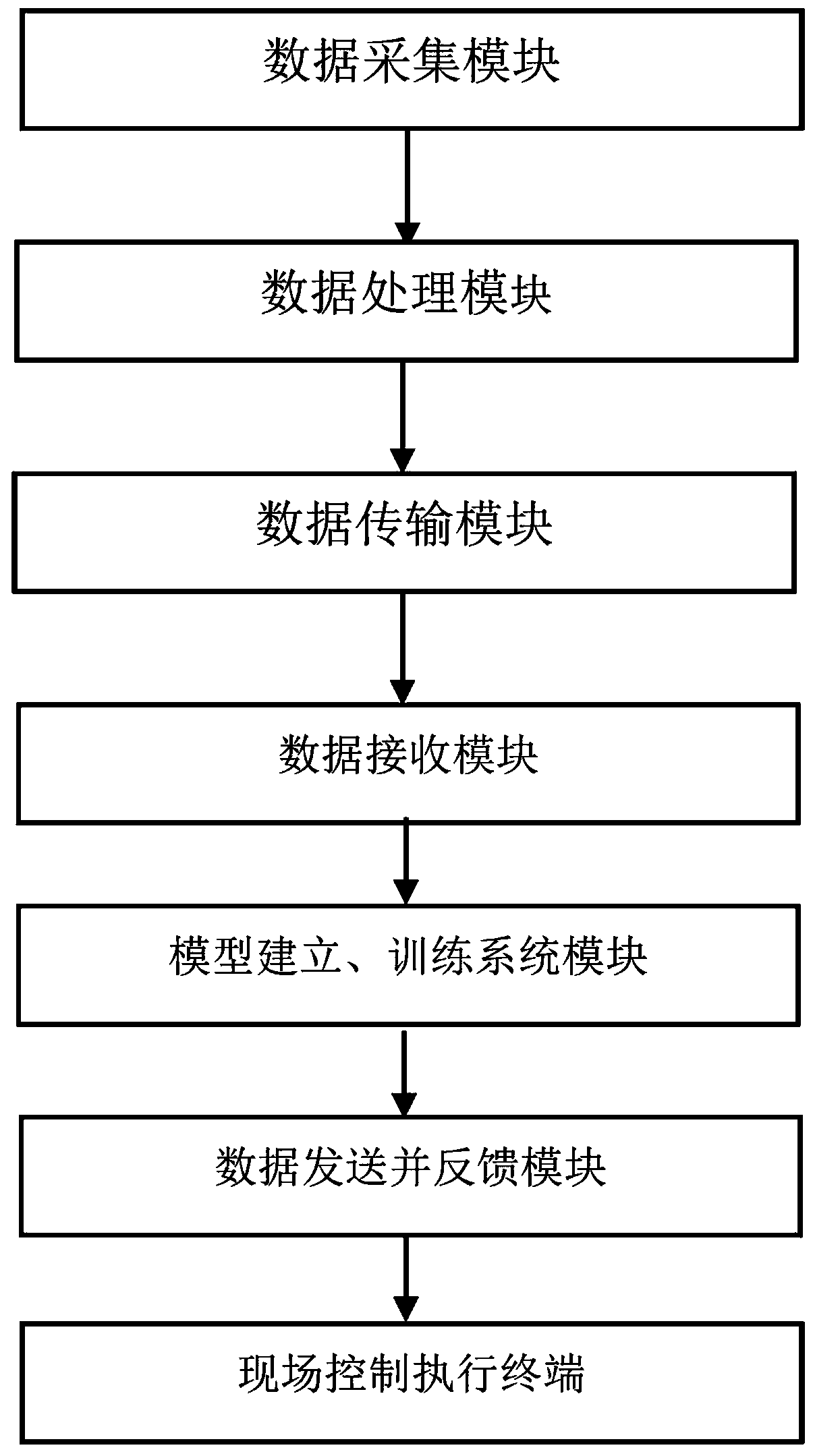

[0030] as attached Figure 1-2 As shown, the method of the present invention includes: collecting a large amount of data information in the hazardous waste incineration system from design, installation, commissioning to operation stages, these data information include process equipment data information, equipment operating condition parameter data information, main and auxiliary feed materials Data information and smoke emission data information. Use the data information to establish data information modules for hazardous waste incineration process equipment, equipment operating condition parameter data information modules, main and auxiliary feed data information modules, and flue gas emission data information modules, and accumulate and record static and dynamic data information. Temporal time series and recording frequency establish a two-dimensional graph and database. The two-dimensional graph here refers to the timing diagram of the data value of this item.

[0031] Tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com